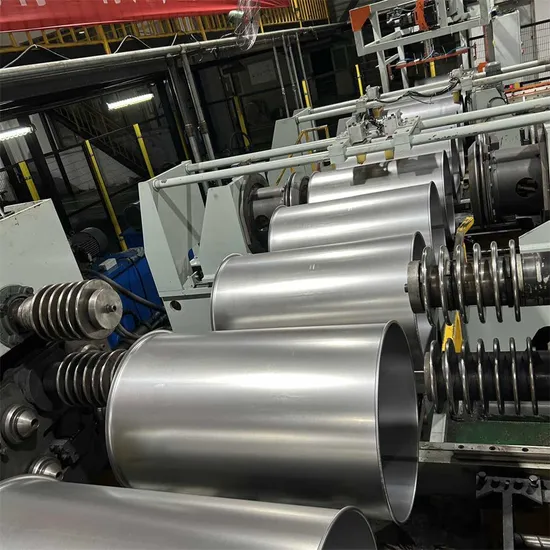

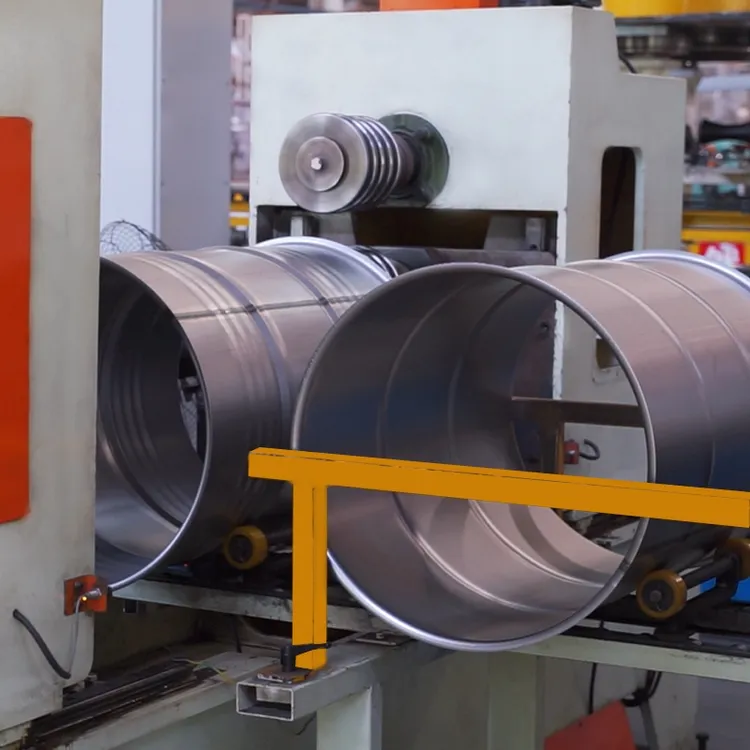

The global stainless steel barrel market is experiencing steady growth, driven by increasing demand across industries such as food and beverage, pharmaceuticals, chemicals, and renewable energy. According to Grand View Research, the global stainless steel tanks and vessels market was valued at USD 47.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by stringent hygiene regulations, the material’s corrosion resistance, and its recyclability, making stainless steel a preferred choice for storage and transport solutions. With 55-gallon stainless steel barrels being a staple in bulk handling and industrial applications, the need for reliable, high-quality manufacturers has never been greater. As production volumes rise and sustainability standards tighten, leading manufacturers are investing in advanced fabrication technologies and quality certifications to meet evolving global demands. Below are the top 8 manufacturers recognized for their innovation, product consistency, and market reach in producing 55-gallon stainless steel barrels.

Top 8 55 Gallon Stainless Steel Barrel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Buy Steel Drums, Heavy Duty Drums, and More

Domain Est. 2005

Website: mcmanusdrum.com

Key Highlights: At McManus Drum Co. Inc., we offer heavy-duty 55-gallon plastic drums that are suitable for a variety of applications, including the storage of liquids ……

#2 55 Gallon Drum Manufacturers

Website: 55gallondrumcompanies.com

Key Highlights: For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons ……

#3 Stainless Steel Drums

Domain Est. 1996

Website: skolnik.com

Key Highlights: We manufacture our stainless steel drums either as a conventional welded seam or crevice-free, seamless design. Unit of Measurement Selector….

#4 55 gal Stainless Steel Wine Barrels

Domain Est. 1997

Website: berlinpackaging.com

Key Highlights: Store wine and fruit wine when ageing is not required in these 55 gal Stainless Steel Wine Barrels from Berlin Packaging. Shop today for great prices!…

#5 55 Gallon Steel Drums

Domain Est. 1997

Website: bascousa.com

Key Highlights: 5-day delivery 30-day returns55 Gallon Steel Drums Available Now with no Minimum Order Size. Order now on phone or online!…

#6 Heavy Duty Stainless Steel Drums

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: 30-day returnsBrowse stainless steel drums in various sizes, from 5 to 85 gallons. We also carry top-selling stainless steel 55 gallon drums — Wholesale Pricing….

#7 55 Gallon Seamless Stainless Steel Barrel

Domain Est. 2012

#8 Safe Drum Handling Company

Domain Est. 2013

Website: safedrumhandling.com

Key Highlights: Stainless Steel Drum Handling Equipment for repositioning, lifting, moving, palletizing, mixing and pouring 55 gallon (208 liter) drums and barrels. Stainless ……

Expert Sourcing Insights for 55 Gallon Stainless Steel Barrel

H2: Projected 2026 Market Trends for 55 Gallon Stainless Steel Barrels

The global market for 55-gallon stainless steel barrels is poised for steady growth by 2026, driven by increasing demand across key industrial sectors, sustainability initiatives, and technological advancements in material science and manufacturing. Below is an analysis of the major market trends expected to shape the industry in 2026:

-

Rising Demand in Food & Beverage and Pharmaceutical Industries

Stainless steel barrels are essential in hygienic applications due to their corrosion resistance, durability, and ease of sterilization. By 2026, the food and beverage and pharmaceutical sectors are expected to be the primary growth drivers. With heightened regulatory standards for sanitation and contamination control—especially in emerging markets—the preference for stainless steel over plastic or carbon steel containers will continue to rise. -

Growth in Renewable Energy and Chemical Storage Applications

The expansion of biofuel production, hydrogen energy projects, and specialty chemical manufacturing will increase the need for reliable, long-term storage solutions. Stainless steel barrels offer superior resistance to reactive chemicals and high-pressure environments, making them ideal for handling aggressive substances. As green energy infrastructure scales up globally, demand for these barrels in transport and temporary storage will grow. -

Emphasis on Sustainability and Reusability

Environmental regulations and corporate sustainability goals are pushing industries to adopt reusable packaging. Unlike single-use plastic or coated steel drums, 55-gallon stainless steel barrels can be cleaned, sanitized, and reused hundreds of times, reducing waste and lifecycle costs. By 2026, companies will increasingly opt for stainless steel to align with ESG (Environmental, Social, and Governance) objectives, supporting circular economy models. -

Regional Market Shifts and Manufacturing Relocation

Asia-Pacific, particularly China and India, will emerge as both major producers and consumers of stainless steel barrels due to rapid industrialization and infrastructure development. Simultaneously, nearshoring trends in North America and Europe may lead to increased regional manufacturing of stainless steel containers to reduce supply chain vulnerabilities, especially post-pandemic and amid ongoing geopolitical tensions. -

Technological Advancements and Customization

Innovation in welding techniques, surface finishing (e.g., electropolishing), and smart integration (e.g., embedded sensors for temperature or pressure monitoring) will enhance barrel performance and traceability. By 2026, customized stainless steel barrels with IoT-enabled tracking capabilities could gain traction in logistics and high-value chemical transport, improving safety and compliance. -

Price Volatility and Raw Material Challenges

The market may face fluctuations due to the cost of raw materials like nickel and chromium, key components of stainless steel. Supply chain disruptions or trade policies affecting metal imports could impact pricing. However, advances in recycling technologies and the use of lower-nickel alloys may help mitigate cost pressures. -

Competitive Landscape and Consolidation

The market is expected to see consolidation among mid-sized manufacturers as larger players acquire niche suppliers to expand product offerings and geographic reach. Differentiation through quality certifications (e.g., FDA, 3A, ASME), fast turnaround times, and value-added services will become key competitive advantages.

In summary, the 55-gallon stainless steel barrel market in 2026 will be shaped by regulatory demands, sustainability trends, and industrial expansion in high-growth sectors. Companies that invest in innovation, regional supply chains, and environmental stewardship will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing 55 Gallon Stainless Steel Barrels (Quality & IP)

Sourcing 55-gallon stainless steel barrels requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to significant operational, financial, and legal risks. Below are common pitfalls to avoid:

Quality-Related Pitfalls

1. Incorrect Stainless Steel Grade Selection

Using substandard or inappropriate stainless steel grades (e.g., 304 instead of 316L) can result in corrosion, contamination, and premature failure—especially in corrosive or sanitary environments. Always verify the grade meets industry standards (e.g., ASTM A240) and application requirements (e.g., food, pharmaceutical, chemical).

2. Poor Fabrication and Welding Practices

Inadequate welding techniques can compromise structural integrity and hygiene. Look for fully TIG-welded seams, proper passivation, and absence of crevices. Poor welds lead to pitting, bacterial growth, and leaks, particularly under pressure or thermal cycling.

3. Inadequate Surface Finish

Barrels used in sanitary applications require specific surface finishes (e.g., Ra ≤ 0.8 µm for pharmaceutical use). Suppliers may cut corners with rougher finishes that harbor contaminants and are difficult to clean, violating FDA or 3-A standards.

4. Lack of Proper Certification and Traceability

Failing to obtain material test reports (MTRs), mill certificates, or compliance documentation (e.g., FDA, ASME) can result in non-compliance with regulatory requirements. Always demand full traceability of materials and manufacturing processes.

5. Substandard Fittings and Accessories

Low-quality bungs, valves, or lids made from inferior materials can become contamination points or fail under operational stress. Ensure all components match the barrel’s grade and are certified for the intended use.

Intellectual Property (IP)-Related Pitfalls

1. Sourcing Counterfeit or IP-Infringing Products

Some suppliers replicate branded barrel designs (e.g., TriClamp fittings, proprietary venting systems) without authorization. Using such barrels may expose your company to legal liability for contributory infringement or damage brand reputation.

2. Unauthorized Use of Patented Designs

Certain barrel configurations—such as specialized drainage, lifting features, or modular stacking systems—may be protected by patents. Sourcing from unauthorized manufacturers risks infringement lawsuits, especially in regulated industries.

3. Lack of IP Due Diligence in Supplier Vetting

Failing to verify that a supplier has the right to produce and sell specific designs can lead to supply chain disruptions if IP disputes arise. Conduct due diligence by reviewing supplier IP licenses or design registrations.

4. Misrepresentation of Compliance and Branding

Suppliers may falsely claim their barrels are “FDA-compliant” or “equivalent to Brand X,” misleading buyers. Such misrepresentation can constitute false advertising and expose your business to regulatory and legal risk.

5. Inadequate Contractual IP Protections

Purchase agreements often lack clauses addressing IP ownership, indemnification for infringement, or warranty of non-infringement. Always include strong IP provisions to shield your organization from third-party claims.

Best Practices to Avoid Pitfalls

- Require full documentation: MTRs, compliance certificates, and design specifications.

- Audit suppliers: Conduct on-site or third-party audits of manufacturing facilities.

- Verify IP status: Consult legal counsel to assess risk when sourcing non-OEM barrels.

- Use reputable suppliers: Prefer vendors with a proven track record and transparent supply chains.

- Include IP clauses in contracts: Ensure indemnification and warranty of non-infringement.

By proactively addressing both quality and IP concerns, organizations can ensure reliable, compliant, and legally sound sourcing of 55-gallon stainless steel barrels.

H2: Logistics & Compliance Guide for 55 Gallon Stainless Steel Barrel

The 55-gallon stainless steel barrel is a durable, reusable industrial container commonly used for the storage and transport of high-value, sensitive, or regulated materials such as chemicals, pharmaceuticals, food products, and hazardous substances. Proper logistics planning and regulatory compliance are essential to ensure safety, environmental protection, and adherence to international and national standards.

1. Product Specifications Overview

- Capacity: 55 gallons (approximately 208 liters)

- Material: 304 or 316 stainless steel (corrosion-resistant, non-reactive)

- Weight: Empty weight typically ranges from 85 to 120 lbs (38–54 kg), depending on wall thickness and construction

- Dimensions: Standard height ~34.5 in (87.6 cm), diameter ~23 in (58.4 cm)

- Lid Type: Removable full-open or 2”/3/4” bung closure

- Features: Often includes lifting rings, forklift skids, and UN/DOT certification

2. Transportation Logistics

A. Mode of Transport

– Truck: Most common. Use pallets or cradles to secure barrels. Forklift access required at loading/unloading points.

– Rail & Sea: Suitable for large shipments. Ensure proper lashing and documentation.

– Air: Rare due to weight and cost; requires special approval for hazardous contents.

B. Securing and Stacking

– Stacking: Generally safe up to 3–4 high when empty and on stable pallets. Loaded barrels should not be stacked unless designed for it.

– Securing: Use straps, dunnage, or containers to prevent rolling or shifting during transit.

– Palletization: Mount on wooden or plastic pallets (48″x40″) for forklift handling and stability.

C. Handling Equipment

– Forklifts, pallet jacks, barrel tilters, or drum movers required.

– Use lifting rings or chocks for safe movement.

D. Environmental Considerations

– Avoid exposure to extreme temperatures or moisture during storage and transport.

– Store upright to prevent leakage and contamination.

3. Regulatory Compliance

A. UN/DOT Certification

– If transporting hazardous materials (HAZMAT), the barrel must be UN-rated (e.g., UN 1A1/Y), indicating:

– Material (1A = steel)

– Packaging type (1 = non-removable head)

– Performance level (Y = medium hazard)

– Certification includes passing drop, stack, and leakproof tests.

B. Hazardous Materials Regulations (49 CFR, U.S.)

– Labeling: Proper hazard class labels (e.g., flammable, corrosive), orientation arrows, and UN number.

– Placarding: Vehicles must display correct placards based on material class and quantity.

– Documentation: Shipper must provide a Hazardous Materials Shipping Paper (e.g., Bill of Lading with HAZMAT details).

C. International Compliance

– IMDG Code (sea): Required for ocean freight; includes stowage, segregation, and documentation.

– IATA Dangerous Goods Regulations (air): Apply if shipped by air; stricter than ground rules.

– ADR (Europe): For road transport in Europe; similar framework to DOT.

D. EPA & Environmental Regulations

– Spill Prevention: Secondary containment required if storing hazardous or regulated substances.

– SPCC Plan: Facilities storing >1,320 gallons of oil may need a Spill Prevention, Control, and Countermeasure plan.

– RCRA: If containing hazardous waste, must comply with manifesting, labeling, and storage rules.

E. FDA & Food-Grade Compliance

– For food, beverage, or pharmaceutical use:

– Barrel must meet FDA 21 CFR standards.

– Be certified as 3-A Sanitary Standards compliant if used in dairy or food processing.

– Maintain cleaning and sanitation records.

4. Labeling and Marking Requirements

Each barrel must display:

– UN Mark: e.g., UN 1A1/Y1.8/150/23 USA (indicating type, strength, year, country)

– Manufacturer & Date of Production

– Capacity (55 gal / 208 L)

– Material Type (e.g., SS 316)

– Hazard Labels (if applicable)

– Proper Shipping Name & UN Number (for HAZMAT)

5. Storage Best Practices

- Store in dry, ventilated, temperature-controlled areas.

- Keep away from incompatible materials (e.g., acids near bases).

- Use spill trays or bunded storage for liquids.

- Rotate stock (FIFO) to prevent long-term degradation.

6. Cleaning and Reuse

- Decontamination: Required before reuse, especially for hazardous or regulated materials.

- Validation: For pharmaceutical/food use, cleaning must be validated (e.g., residue testing).

- Inspection: Check for dents, corrosion, or seal damage before reuse.

7. End-of-Life & Recycling

- Stainless steel barrels are 100% recyclable.

- Dispose of via certified metal recyclers.

- If contaminated with hazardous waste, follow RCRA disposal protocols.

8. Documentation & Recordkeeping

Maintain:

– UN certification documents

– HAZMAT shipping papers

– Cleaning and inspection logs

– Training records for HAZMAT handlers (required under DOT 49 CFR §172.704)

Summary

The 55-gallon stainless steel barrel is a robust solution for industrial logistics, but its use demands strict adherence to safety and compliance standards. Whether transporting hazardous chemicals or sterile food products, proper handling, certification, labeling, and documentation are critical to ensure regulatory compliance, worker safety, and environmental protection.

Always consult the latest versions of:

– 49 CFR (DOT)

– OSHA 29 CFR 1910

– EPA Regulations (40 CFR)

– UN Model Regulations

– Industry-specific standards (e.g., FDA, 3-A)

For tailored compliance, engage a certified Dangerous Goods Safety Advisor (DGSA) or regulatory consultant.

In conclusion, sourcing a 55-gallon stainless steel barrel requires careful consideration of material quality, intended application, supplier reliability, and cost-effectiveness. Stainless steel barrels offer durability, corrosion resistance, and easy maintenance, making them ideal for industries such as food and beverage, pharmaceuticals, chemical storage, and sustainable agriculture. When selecting a supplier, it is essential to verify certifications (such as food-grade 304 or 316 stainless steel), ensure compliance with industry standards, and evaluate lead times and logistics. Additionally, considering reconditioned or custom-fabricated options can provide cost savings without compromising performance. By conducting thorough research and due diligence, businesses can secure a reliable, long-term solution that meets both operational needs and regulatory requirements.