The global plastic drums market is experiencing steady growth, driven by rising demand across industries such as chemicals, pharmaceuticals, food & beverage, and agriculture. According to Grand View Research, the global industrial plastic packaging market was valued at USD 195.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030, with plastic drums representing a significant segment of this demand due to their durability, reusability, and transport efficiency. As industries prioritize cost-effective and sustainable packaging solutions, the need for high-quality 55-gallon plastic drums—particularly those meeting rigorous specifications for material composition, drop resistance, and regulatory compliance—has intensified. With North America and Europe leading in production and consumption, manufacturers are increasingly focused on innovation in drum design, including UV resistance, stackability, and UN certification standards. This report identifies the top 6 manufacturers distinguished by their technical precision, material quality, global compliance, and scale of output in the 55-gallon plastic drum segment.

Top 6 55 Gallon Plastic Drum Specifications Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 55 Gallon Drum Manufacturers

Website: 55gallondrumcompanies.com

Key Highlights: A 55 gallon plastic drum is a storage or shipping container made of a high density industrial strength polymer with thick walls that provide endurance, strength ……

#2 55 Gallon Blue Straight

Domain Est. 1996

Website: usplastic.com

Key Highlights: In stock $162.05 deliveryDurable & lightweight blow-molded HDPE · UV resistant, weather & chemical resistant · Inside Dimensions: 20-1/16″ Top Dia. · Outside Dimensions: 21″ Top Di…

#3 Blue 55 Gal Plastic Drum Barrel

Domain Est. 1997

Website: eagle.justrite.com

Key Highlights: In stock $56.51 deliveryEagle Blue 55 Gallon Plastic Drum is constructed of blue blow-molded high-density polyethylene (HDPE) with UV inhibitors, is durable and lightweight….

#4 55 Gallon Closed

Domain Est. 1997

#5 55 Gallon Drums & Accessories

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: 30-day returnsThe outside 55 gallon drum dimensions are typically 23″ (584 mm) diameter and 34.5″ (876 mm) height. Tight-head drums typically have an outside height of 35.25″ ……

#6 55 Gallon Drum Manufacturers and Suppliers

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: Find 55 gallon drum companies that can design, engineer, and manufacture 55 gallon drums to your companies specifications….

Expert Sourcing Insights for 55 Gallon Plastic Drum Specifications

2026 Market Trends for 55 Gallon Plastic Drum Specifications

As the global industrial and chemical sectors evolve, the demand for reliable, durable, and compliant packaging solutions continues to shape the market for 55-gallon plastic drums. By 2026, several key trends are expected to influence the specifications, production, and usage of these essential containers. This analysis explores the anticipated developments in material composition, design standards, sustainability requirements, regulatory compliance, and technological advancements that will define the 55-gallon plastic drum market in the coming years.

Material and Construction Innovations

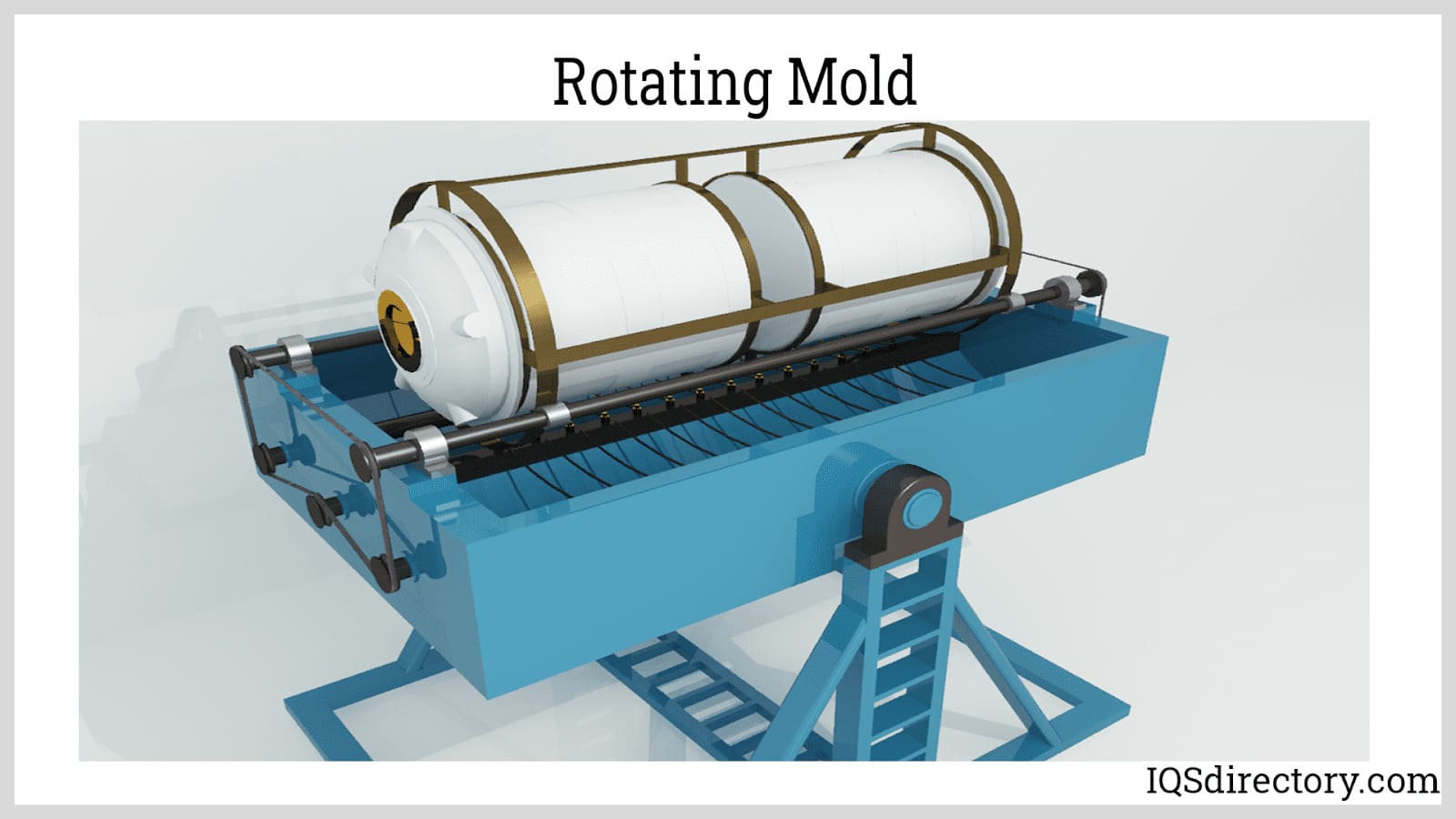

By 2026, high-density polyethylene (HDPE) will remain the dominant material for 55-gallon plastic drums due to its excellent chemical resistance, strength-to-density ratio, and recyclability. However, advancements in polymer science are expected to introduce modified HDPE blends with enhanced properties such as improved UV resistance, higher impact strength, and reduced permeability. Co-extruded layers incorporating barrier materials may become more common for drums intended to store volatile organic compounds (VOCs) or sensitive food-grade products, helping meet stricter emissions and contamination standards.

Additionally, the adoption of recycled HDPE content is projected to rise significantly. Driven by corporate sustainability goals and tightening environmental regulations, manufacturers are expected to offer drums containing 30–50% post-consumer recycled (PCR) content without compromising structural integrity. This shift will necessitate tighter quality controls during the reprocessing phase to ensure consistent drum performance.

Design and Functional Enhancements

In 2026, 55-gallon drum designs will increasingly prioritize user safety, ergonomics, and automation compatibility. Key specification trends include:

- Improved closure systems: Tamper-evident and leak-proof closures—such as ring-seal lids with enhanced gasket materials (e.g., EPDM or fluorocarbon)—will become standard, especially for hazardous material transport.

- Integrated labeling and traceability: Drums will feature molded-in barcode or QR code areas, and some may incorporate RFID tags embedded in the rim or base to support supply chain tracking and inventory management.

- Stackability and handling: Drum dimensions will continue to conform to ISO pallet standards (e.g., 22.5” diameter, 34.5” height), with reinforced chimes and bases to support higher stacking loads in automated warehouses. Lightweight designs that maintain drop-test compliance will gain traction to reduce shipping costs and carbon footprint.

Sustainability and Regulatory Compliance

Environmental regulations will play a central role in shaping drum specifications by 2026. The European Union’s Single-Use Plastics Directive, U.S. EPA guidelines, and extended producer responsibility (EPR) laws in multiple jurisdictions will push manufacturers toward circular economy models. As a result:

- Drums will be designed for multiple reuse cycles, with specifications emphasizing durability, ease of cleaning, and resistance to degradation from repeated use.

- Markings indicating recyclability, material content (e.g., “HDPE 2 – 50% PCR”), and proper end-of-life handling will become mandatory in many markets.

- Reconditioned drum markets will grow, supported by standardized testing and certification protocols (e.g., UN reconditioning standards) to ensure safety and performance parity with new drums.

Industry-Specific Customization

Different sectors will drive divergent specification needs:

- Chemical and pharmaceutical industries will demand drums with FDA or USP Class VI compliance, low extractables, and electrostatic dissipative (ESD) properties to prevent ignition in flammable environments.

- Food and beverage sectors will require drums certified for food contact (e.g., NSF/ANSI 61), with smooth interiors to prevent bacterial growth and facilitate cleaning.

- Agricultural and fertilizer markets will favor UV-stabilized drums with high resistance to acids and salts, often with translucent bodies to allow level visibility.

Technological Integration and Smart Drums

Emerging digital technologies may begin to influence drum specifications by 2026. “Smart drums” equipped with embedded sensors to monitor internal pressure, temperature, or fill levels could enter niche markets, particularly in pharmaceuticals or high-value chemicals. While widespread adoption may still be limited due to cost, pilot programs and industry partnerships are likely to expand, setting the stage for broader integration in the next decade.

Conclusion

The 2026 market for 55-gallon plastic drums will be defined by a convergence of sustainability mandates, regulatory rigor, and technological innovation. Specifications will increasingly emphasize recyclability, safety, traceability, and performance across diverse applications. Manufacturers that proactively adapt to these trends—by investing in advanced materials, modular designs, and circular business models—are poised to lead the evolving global packaging landscape.

Common Pitfalls When Sourcing 55 Gallon Plastic Drums: Quality and IP (Intellectual Property) Concerns

Sourcing 55-gallon plastic drums, especially for critical applications involving chemicals, food, or hazardous materials, requires careful attention to specifications. Overlooking key quality factors or intellectual property (IP) rights can lead to safety hazards, regulatory non-compliance, financial loss, and legal liabilities. Below are common pitfalls to avoid:

1. Neglecting Material Grade and Resin Specifications

One of the most frequent mistakes is assuming all plastic drums are created equal. Not all high-density polyethylene (HDPE) or polypropylene is suitable for every application.

- Pitfall: Failing to verify the exact resin type (e.g., virgin vs. recycled content), resin grade (e.g., FDA-compliant, USP Class VI, NSF), and additives (e.g., UV stabilizers, antioxidants). Using drums with recycled content in food or pharmaceutical applications violates regulations.

- Consequence: Chemical incompatibility, leaching of contaminants, product degradation, or regulatory rejection.

- Solution: Demand detailed material certifications (e.g., CoA – Certificate of Analysis) and confirm resin meets required standards (e.g., FDA 21 CFR, USP, NSF/ANSI 61).

2. Overlooking UN/DOT Certification for Hazardous Materials

Shipping or storing hazardous materials requires drums that meet specific international safety standards.

- Pitfall: Procuring drums without proper UN/DOT certification markings (e.g., UN 1H1/Y1.8/150/XX) or assuming certification covers all chemicals.

- Consequence: Inability to legally transport hazardous goods, safety risks during transit, fines from regulatory bodies (e.g., PHMSA), and potential environmental incidents.

- Solution: Verify the drum’s UN rating matches the specific hazard class, packing group, and specific gravity of your material. Inspect certification documentation and physical markings.

3. Ignoring Compatibility with Intended Contents

Chemical resistance varies significantly between resins and additives, even within the same drum type.

- Pitfall: Assuming a drum labeled “chemical resistant” is suitable for your specific chemical without testing or consulting compatibility charts.

- Consequence: Swelling, cracking, permeation, or catastrophic failure leading to spills, exposure, and contamination.

- Solution: Consult the manufacturer’s chemical compatibility guide for your exact chemical(s) and concentration. Conduct real-world testing under expected conditions (temperature, duration).

4. Underestimating Structural Integrity and Performance Standards

Drum performance under stress is crucial for safety and logistics.

- Pitfall: Not specifying requirements for drop tests, hydrostatic pressure, stacking strength, or top-load capacity.

- Consequence: Drum failure during handling, shipping, or storage—leading to leaks, product loss, and workplace hazards.

- Solution: Require test data (e.g., ASTM D695 for compression, ASTM D880 for impact) and ensure drums meet performance standards for your supply chain (e.g., stacking height, forklift handling).

5. Overlooking Closure and Gasket Compatibility

The closure system (bungs, lids) is as critical as the drum body.

- Pitfall: Using incompatible gasket materials (e.g., Buna-N, EPDM, PTFE) that degrade when exposed to certain chemicals or temperatures.

- Consequence: Leaks, vapor emissions, pressure build-up, or difficulty opening/closing.

- Solution: Specify gasket material based on chemical and temperature compatibility. Ensure closures are properly torqued and meet required sealing standards.

6. Failing to Address Intellectual Property (IP) and Counterfeit Risks

Using or sourcing branded drums without authorization can lead to legal issues.

- Pitfall: Purchasing or using drums bearing trademarks, logos, or patented designs (e.g., specific venting systems, closure mechanisms) without a license. This includes “look-alike” drums from unauthorized suppliers.

- Consequence: Infringement lawsuits, seizure of goods, reputational damage, and supply chain disruptions.

- Solution: Source from authorized distributors or manufacturers. Verify IP rights if customizing or branding drums. Avoid suppliers offering “generic” versions of well-known patented designs.

7. Inadequate Quality Assurance and Traceability

Lack of documentation undermines quality control.

- Pitfall: Accepting drums without batch traceability, quality control records, or lot-specific testing data.

- Consequence: Inability to investigate failures, recall affected batches, or prove compliance during audits.

- Solution: Require full traceability (resin lot numbers, manufacturing dates, test results) and implement incoming inspection protocols.

8. Prioritizing Lowest Price Over Total Cost of Ownership

The cheapest drum can be the most expensive in the long run.

- Pitfall: Selecting suppliers based solely on unit price without considering durability, compliance, and failure risks.

- Consequence: Higher long-term costs due to leaks, contamination, regulatory fines, downtime, and environmental clean-up.

- Solution: Perform a total cost analysis including compliance, safety, lifespan, and potential liability.

By proactively addressing these common pitfalls—particularly around material quality, regulatory compliance, chemical compatibility, and IP rights—purchasers can ensure the safe, legal, and cost-effective sourcing of 55-gallon plastic drums.

Logistics & Compliance Guide for 55 Gallon Plastic Drum Specifications

Overview of 55 Gallon Plastic Drums

55 gallon plastic drums are widely used in industrial, chemical, pharmaceutical, and food-grade applications for the safe storage and transportation of liquids, semi-solids, and dry materials. Constructed primarily from high-density polyethylene (HDPE), these drums offer excellent chemical resistance, durability, and recyclability. Understanding their specifications is critical to ensuring compliance with international, national, and industry-specific regulations during logistics operations.

Key Physical and Material Specifications

Capacity & Dimensions

– Nominal capacity: 55 US gallons (208 liters)

– Typical dimensions: 22.5 inches (57.2 cm) diameter × 34.5 inches (87.6 cm) height

– Weight: 18–25 lbs (8–11 kg), depending on wall thickness and design

Material Composition

– Primary material: High-density polyethylene (HDPE)

– UV-stabilized and FDA-compliant options available for food, beverage, and pharmaceutical use

– May include additives for flame retardancy or anti-static properties (e.g., for flammable materials)

Closure Types

– Open Head (Removable Head): Features a full-top opening with a bolt ring or lever lock closure. Suitable for solids, viscous materials, or cleaning.

– Tight Head (Closed Top): Equipped with 2” and 3/4” NPT bung openings. Ideal for liquids and pressurized contents.

UN/DOT Certification and Hazardous Materials Compliance

UN Rating Requirements

– Drums used for hazardous materials must meet UN performance standards (UN 1H1 for plastic drums)

– Markings include: UN symbol, packaging code, packing group (I, II, III), maximum gross mass, and manufacturer details

– Must pass drop, stack, and hydraulic pressure tests per 49 CFR and UN Recommendations on the Transport of Dangerous Goods

Packing Groups

– Group I: High hazard (e.g., strong acids, solvents)

– Group II: Medium hazard

– Group III: Low hazard

– Drum wall thickness and design vary based on required packing group

DOT & IATA Regulations

– Compliance with 49 CFR (U.S. Department of Transportation) is mandatory for domestic U.S. transport

– IATA Dangerous Goods Regulations apply to air freight

– IMDG Code governs international maritime shipments

Regulatory Compliance and Industry Standards

FDA & Food-Grade Certification

– For food, pharmaceutical, or potable water use, drums must comply with FDA 21 CFR 177.1520

– Must be manufactured using food-safe resins and processing methods

– Often marked “FDA Approved” or “Food Grade”

Environmental and Sustainability Standards

– HDPE drums are recyclable (Resin Identification Code #2)

– Reconditioned or remanufactured drums must meet RIPA (Reconditioned Industrial Packaging Association) standards

– Some regions require tracking of drum lifecycle under extended producer responsibility (EPR) laws

OSHA & WHMIS Considerations

– Drums must be compatible with stored substances to prevent degradation or leaks

– Secondary containment may be required under OSHA 29 CFR 1910.106 for flammable liquids

– Proper labeling per GHS (Globally Harmonized System) and WHMIS (Canada) is mandatory for hazardous contents

Logistics and Handling Best Practices

Stacking and Storage

– Maximum stack height typically 4–5 drums when filled, depending on drum rating and warehouse floor load capacity

– Store in cool, dry, UV-protected areas to prevent material degradation

– Use pallets and ensure uniform load distribution

Transportation Requirements

– Secure drums upright using straps, dunnage, or containment systems to prevent shifting

– For hazardous materials, use compatible absorbents and spill kits

– Avoid mixed loads with incompatible substances (e.g., acids and bases)

Labeling and Documentation

– Clearly display UN markings, hazard labels, and handling instructions

– Maintain shipping papers, Safety Data Sheets (SDS), and manifests as required by jurisdiction

– Include drum batch/lot number for traceability in case of recalls or incidents

Inspection and Maintenance Guidelines

Pre-Use Inspection

– Check for cracks, dents, leaks, or stress marks

– Verify bung threads are undamaged and seals are intact

– Confirm compatibility with intended contents using chemical resistance charts

Reconditioning Standards

– Reconditioned drums must undergo cleaning, testing, and relabeling per RIPA or EPA 40 CFR 261.4(a)(23)

– Prohibited for certain hazardous wastes unless specifically authorized

End-of-Life Management

– Recycle through certified HDPE recyclers

– Follow local, state, and federal regulations for disposal of contaminated drums

Conclusion

Proper selection, handling, and compliance management of 55 gallon plastic drums are essential for safe logistics operations and regulatory adherence. Ensuring drums meet UN/DOT specifications, industry standards, and environmental guidelines minimizes risks and supports sustainable supply chain practices. Always consult the latest regulatory publications and work with certified suppliers to maintain compliance across transportation modes and jurisdictions.

Conclusion: Sourcing 55-Gallon Plastic Drum Specifications

In sourcing 55-gallon plastic drums, it is essential to carefully evaluate key specifications to ensure suitability for the intended application, regulatory compliance, and long-term performance. Critical factors include material composition (typically high-density polyethylene or HDPE), drum dimensions, weight, closure type (e.g., open-head or tight-head), UN ratings for hazardous material transport, and resistance to specific chemicals, UV exposure, and environmental conditions.

Additionally, considerations such as recyclability, stacking strength, compatibility with handling equipment (e.g., forklifts, drum handlers), and certifications (such as FDA compliance for food-grade use or USDA approval) play a significant role in selecting the right drum. Suppliers should provide detailed technical data sheets and test certifications to validate performance claims.

Ultimately, aligning drum specifications with operational needs—whether for storage, transport, or disposal of liquids or solids—ensures safety, efficiency, and cost-effectiveness. A thorough assessment of these specifications, combined with reliable supplier partnerships, enables informed procurement decisions and supports sustainable and compliant industrial operations.