The global aluminum alloy market continues to expand, driven by rising demand in aerospace, automotive, marine, and construction industries. According to a 2023 report by Mordor Intelligence, the market is projected to grow at a CAGR of 5.8% from 2023 to 2028, fueled by the increasing adoption of lightweight materials to enhance fuel efficiency and reduce emissions. Among the most widely used aluminum alloys, 5052 and 6061 stand out for their distinct mechanical properties and versatility—5052 for its excellent corrosion resistance and formability, 6061 for its superior strength and weldability. As demand for high-performance aluminum solutions rises, manufacturers specializing in these alloys are scaling production and advancing alloy processing technologies. This growing competitive landscape underscores the importance of identifying leading suppliers that consistently deliver quality, innovation, and reliability. Below, we highlight the top seven manufacturers excelling in the production of 5052 and 6061 aluminum alloys, based on market presence, product range, and performance metrics.

Top 7 5052 Vs 6061 Aluminum Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industry Standards

Domain Est. 1998

Website: aluminum.org

Key Highlights: For 70 years, the Aluminum Association has worked with the industry to develop and maintain technical standards for aluminum production….

#2 Identifying Aluminum 5052 & 6061 Similarities and Differences

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 5052 aluminum is easier to form and bend without cracking. On the other hand, 6061 aluminum is easily extruded into shapes like channels, angles, and tees….

#3 5052

Domain Est. 1999

Website: nemaenclosures.com

Key Highlights: Difference in Properties & Yield Strength Between 5052 vs 6061. 5052-vs-6061-aluminum. By jake | Published January 29, 2020 | Full size is 800 × 2000 pixels…

#4 Difference Between 5052 Aluminum vs 6061 Aluminum

Domain Est. 2015

Website: metalscut4u.com

Key Highlights: 6061 aluminum alloy is considered a more preferable alloy for general use and 5052 aluminum is a more preferable material for welded sheet work and marine ……

#5 10 Differences Between 5052 vs 6061 Aluminum Alloy

Domain Est. 2017

Website: chalcoaluminum.com

Key Highlights: Generally, 6061 aluminum alloy is most suitable for machining, while 5052 is used for sheet metal and welding applications. This kind of ……

#6 Is there a huge difference in machineability between 6061 and 5052 …

Website: forum.makerforums.info

Key Highlights: Yes. 5052 is much more difficult to machine. It does have good formability however. It is used primarily for laser cut + folded parts. 6061 is machinable but ……

#7 5052

Domain Est. 1999

Website: gtrmfg.com

Key Highlights: With higher fatigue strength and elasticity than 6061-T6, aluminum 5052-H32 is a terrific forming alloy. However, this material is “gummier” to ……

Expert Sourcing Insights for 5052 Vs 6061 Aluminum

H2: Market Trends for 5052 vs. 6061 Aluminum in 2026

As the global aluminum market evolves toward sustainable manufacturing, lightweighting in transportation, and advanced fabrication technologies, the competition between two of the most widely used aluminum alloys—5052 and 6061—will be shaped by distinct material properties, industry demands, and regional economic factors in 2026.

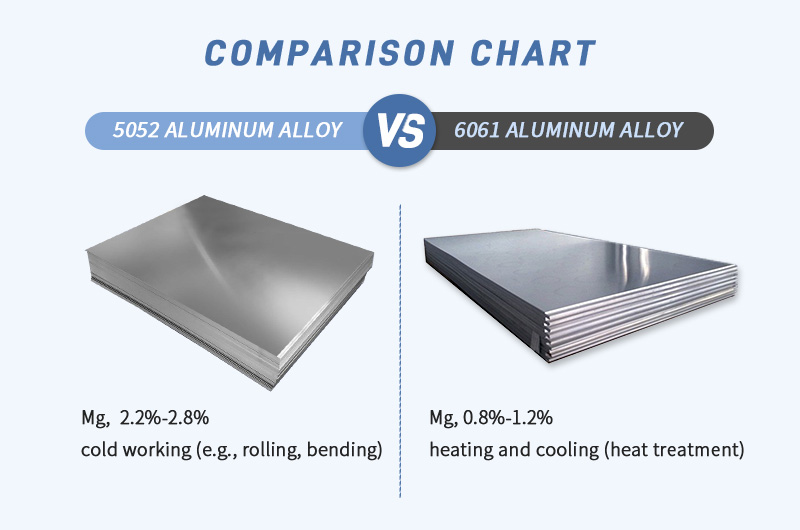

1. Material Properties and Applications Driving Demand

-

Aluminum 5052: Known for its excellent corrosion resistance, moderate strength, and superior workability, 5052 is predominantly used in marine environments, fuel tanks, sheet metal work, and HVAC systems. Its non-heat-treatable nature limits its use in high-stress applications but enhances its appeal in environments requiring durability and formability.

-

Aluminum 6061: A heat-treatable alloy with good mechanical strength, weldability, and machinability, 6061 is favored in structural applications, aerospace components, automotive frames, and consumer electronics. Its versatility in extrusion and fabrication makes it a go-to choice in precision engineering.

By 2026, demand for 6061 is expected to grow at a faster pace than 5052 due to its broader applicability in high-performance sectors, particularly in electric vehicles (EVs) and renewable energy infrastructure.

2. Automotive and Transportation Sector Influence

The global push toward lightweight vehicles to improve fuel efficiency and extend EV range will heavily influence aluminum alloy selection. While both alloys are used in automotive applications, 6061’s higher strength-to-weight ratio makes it more suitable for critical structural components like chassis parts and battery enclosures. In contrast, 5052 remains relevant in non-structural, corrosion-prone areas such as fuel lines and interior panels.

With EV production projected to rise significantly by 2026—particularly in China, Europe, and North America—6061 demand is expected to surge, supported by investments in aluminum-intensive vehicle platforms.

3. Aerospace and Defense Applications

In aerospace, 6061 is widely used for non-critical structural parts, while higher-strength alloys (e.g., 7075) dominate primary load-bearing components. However, 6061’s favorable balance of strength and weldability ensures steady demand. 5052 sees limited use in this sector, primarily in fuel tanks and ducting, where corrosion resistance is paramount.

As commercial air travel rebounds and defense spending increases globally, 6061 will benefit from retrofitting programs and drone technology, where lightweight, durable materials are essential.

4. Construction and Renewable Energy Growth

The construction industry continues to adopt aluminum for façades, roofing, and modular structures. 6061 is preferred for structural framing and solar panel mounting systems due to its extrudability and strength. In solar infrastructure—a sector expected to expand rapidly by 2026—6061 dominates in support structures, further boosting its market share.

5052 retains a niche in roofing and cladding where formability and weather resistance are key, but its growth will be more subdued compared to 6061.

5. Regional Production and Supply Chain Dynamics

China remains the largest producer and consumer of both alloys, but tightening environmental regulations and energy efficiency standards are pushing manufacturers toward higher-value, recyclable alloys. 6061’s compatibility with closed-loop recycling enhances its sustainability profile, aligning with ESG goals.

In North America and Europe, reshoring of manufacturing and investments in green technology favor 6061, supported by local fabrication ecosystems. Meanwhile, 5052 maintains steady demand in marine industries in Southeast Asia and maritime regions.

6. Price and Availability Outlook for 2026

Aluminum prices will remain sensitive to energy costs, alumina supply, and geopolitical factors. 6061 typically commands a slight price premium over 5052 due to alloying elements like silicon and magnesium. However, rising demand and potential supply constraints on magnesium (a key component in both alloys) could tighten margins.

Recycling advancements are expected to stabilize supply, with recycled 6061 gaining favor in eco-conscious industries.

7. Technological and Processing Innovations

Advancements in welding, extrusion, and additive manufacturing will favor 6061, which performs well in automated fabrication lines. The rise of Industry 4.0 and smart manufacturing will increase demand for alloys that integrate seamlessly into precision systems—another edge for 6061.

While 5052 excels in deep-drawing and bending operations, its applications are less aligned with high-tech manufacturing trends.

Conclusion

By 2026, 6061 aluminum is projected to outperform 5052 in market growth, driven by its adaptability to high-tech, lightweight, and sustainable applications in transportation, renewable energy, and construction. While 5052 will maintain a stable presence in marine and general sheet metal industries, its growth trajectory will be more limited. Manufacturers and suppliers should anticipate a shift toward 6061-centric production strategies, supported by innovation, recycling, and global decarbonization efforts.

Common Pitfalls Sourcing 5052 vs 6061 Aluminum: Quality and IP Concerns

When sourcing aluminum alloys, particularly 5052 and 6061, manufacturers and procurement teams often face critical challenges related to material quality and intellectual property (IP) protection. Mistakes in specification, verification, or supplier management can lead to component failure, compliance issues, or loss of competitive advantage. Below are the most common pitfalls to avoid.

1. Confusing Alloy Properties and Applications

One of the most frequent sourcing errors is misapplying 5052 and 6061 due to misunderstanding their mechanical and chemical differences.

-

Pitfall: Using 5052 in high-stress structural applications where 6061 is required.

5052 is a non-heat-treatable alloy known for excellent corrosion resistance and formability, making it ideal for marine environments and sheet metal fabrication. However, it has lower strength (30–35 ksi UTS) compared to 6061 (45–50 ksi UTS after T6 temper), which is heat-treatable and commonly used in aerospace, automotive, and structural frames. -

Consequence: Premature failure under load, warranty claims, and safety risks.

-

Solution: Clearly define application requirements (load, environment, weldability) and match alloy properties accordingly. Never substitute without engineering validation.

2. Inadequate Material Certification and Traceability

Lack of proper documentation opens the door to substandard or counterfeit material.

-

Pitfall: Accepting mill certifications (MTCs) without verifying authenticity or alloy composition.

Some suppliers provide falsified or generic certificates. Without traceability (heat lot numbers, ASTM compliance), it’s impossible to confirm the material is truly 5052 or 6061. -

Consequence: Risk of non-compliance with industry standards (e.g., AS9100, ISO 9001), rejected shipments, or field failures.

-

Solution: Require full ASTM B209 (sheet/plate) or ASTM B221 (extrusions) compliance, with certified test reports (CoC) including chemical analysis and mechanical properties. Conduct third-party PMI (Positive Material Identification) testing when sourcing high-risk or critical components.

3. Overlooking Temper Designation Impact

The temper (e.g., H32, T6) significantly affects performance, but is often overlooked during procurement.

-

Pitfall: Sourcing 6061-O (annealed) instead of 6061-T6 (solution heat-treated and artificially aged).

The T6 temper offers nearly double the tensile strength of the O temper. Similarly, 5052-H32 provides better strength and stability than H12 or O tempers. -

Consequence: Reduced part performance, dimensional instability, and assembly issues.

-

Solution: Specify exact temper in purchase orders and drawings. Audit supplier processes to confirm proper heat treatment and aging.

4. Intellectual Property Exposure in Custom Fabrication

When outsourcing machining or forming, IP risks increase significantly—especially with proprietary designs.

-

Pitfall: Sharing detailed CAD models or tooling specs with unvetted suppliers, especially overseas.

Custom 6061 extrusions or 5052 enclosures may reveal unique design features vulnerable to replication. -

Consequence: Loss of competitive edge, reverse engineering by competitors, or unauthorized production.

-

Solution: Use NDAs with enforceable IP clauses. Share only necessary fabrication drawings (not full design intent). Work with trusted suppliers in jurisdictions with strong IP enforcement. Consider split manufacturing (e.g., extrusion in one country, machining in another) to limit exposure.

5. Supply Chain Transparency and Counterfeit Risk

Cost-driven sourcing can lead to supply chains with limited visibility.

-

Pitfall: Purchasing through brokers or secondary distributors without knowing the original mill source.

Recycled or mislabeled aluminum may be passed off as prime 5052 or 6061, especially in high-demand markets. -

Consequence: Inconsistent quality, out-of-spec chemistry (e.g., excess iron or silicon), and processing defects like cracking during bending or welding.

-

Solution: Source directly from reputable mills or certified distributors. Require full chain-of-custody documentation. Perform incoming material inspection with handheld XRF analyzers for alloy verification.

Bottom Line: Accurate sourcing of 5052 and 6061 aluminum requires more than just price comparison. A disciplined approach combining technical understanding, robust certification, and IP protection is essential to ensure performance, reliability, and competitive integrity.

H2: Logistics & Compliance Guide: 5052 vs. 6061 Aluminum

Choosing between 5052 and 6061 aluminum alloys involves critical considerations beyond mechanical properties. This guide outlines key logistics and compliance factors to ensure smooth procurement, processing, and use.

H2.1: Material Sourcing & Supply Chain Logistics

- 5052 Aluminum:

- Availability: Widely available globally, particularly in sheet, plate, and coil forms. Common in marine, chemical, and fuel tank applications.

- Suppliers: Numerous global and regional suppliers (e.g., Novelis, Hydro, Kaiser, local mills). Often stocked by service centers specializing in sheet metal.

- Lead Times: Generally shorter for standard tempers (H32) and common gauges/thicknesses. Custom tempers or large volumes may have longer lead times.

- Form Factors: Primarily sheet, plate, and coil. Less common in complex extrusions or forgings.

- 6061 Aluminum:

- Availability: Extremely widespread, one of the most common structural alloys. Available globally in diverse forms.

- Suppliers: Ubiquitous. Supplied by all major global aluminum producers and countless extruders, forgers, and service centers.

- Lead Times: Standard extrusions, bars, and plate are readily available with short lead times. Complex shapes, specific tempers (T6), or large forgings require longer planning.

- Form Factors: Highly versatile: extrusions (complex profiles), plate, bar (round, square, hex), tube, forgings.

Key Logistics Takeaway: 6061 offers greater form flexibility and potentially shorter lead times for standard structural shapes (especially extrusions), while 5052 is readily available but primarily in sheet/plate form for specific industrial applications.

H2.2: Transportation & Handling Requirements

-

Both Alloys:

- General: Standard aluminum handling applies. Protect from physical damage (dents, scratches), moisture (water spotting), and contamination (dirt, oil, other metals). Use non-metallic slings or padded metal slings.

- Weight: Similar density (~2.7 g/cm³). Logistics calculations (shipping costs, load limits) are comparable for equivalent volumes.

- Packaging: Typically bundled with protective interleave (paper/plastic) for sheet/plate. Extrusions/bars bundled and crated. Ensure packaging prevents movement during transit.

-

5052 Specifics:

- Sheet/Coil Sensitivity: More susceptible to oil canning (oil-canning) and handling dents due to typical use in thinner gauges. Requires careful stacking and support.

- 6061 Specifics:

- Extrusion Handling: Complex profiles require careful support to prevent bending or twisting. T6 temper parts are harder but more brittle; avoid impact.

- Forgings: Handle with care to avoid chipping edges.

Key Logistics Takeaway: Standard aluminum handling suffices, but 5052 sheet requires extra care against dents, while 6061 extrusions need support to maintain dimensional integrity.

H2.3: Regulatory & Compliance Considerations

-

Material Certification (Both Alloys):

- Requirement: Always obtain Mill Test Certificates (MTCs) or Certificates of Conformance (CoC) meeting relevant standards (e.g., ASTM B209, B221, AMS, EN).

- Content: Certificates must specify alloy, temper, dimensions, applicable standard, and test results (chemical composition, mechanical properties). Traceability (heat number) is crucial.

- Industry Specifics: Aerospace (AMS), Pressure Vessels (ASME BPVC), Construction (ASTM), Military (MIL-DTL) have specific certification requirements. Ensure the CoC meets the end-use standard.

-

5052 Compliance Focus:

- Marine & Chemical: Compliance with marine classification society rules (e.g., ABS, DNV, LR) is critical for boat hulls/tanks. May require specific welding procedure qualifications (WPS/PQR) using appropriate filler (e.g., 5356/5556). Chemical resistance must be validated for specific media.

- Food Contact: If used for tanks or processing equipment, verify compliance with FDA 21 CFR 175.300 (indirect food additives) or EU 1935/2004. Surface finish and cleaning procedures matter.

- 6061 Compliance Focus:

- Structural Engineering: Compliance with building codes (e.g., AISC, Eurocode) and design standards (e.g., ADM, AA). Requires precise mechanical property data (especially T6 temper).

- Aerospace: Strict adherence to AMS specifications (e.g., AMS 4027, AMS 4117) for extrusions, forgings, or plate. Traceability and NDT requirements are paramount.

- Pressure Equipment: Compliance with ASME BPVC Section VIII for vessels requires specific material specs (e.g., ASTM B209, B221) and often third-party inspection/certification.

- Transportation: May need to meet specific vibration, impact, or crashworthiness standards (e.g., automotive, rail).

Key Compliance Takeaway: Certification (CoC/MTC) is mandatory. 5052 compliance centers on marine/chemical regulations and welding; 6061 compliance is dominated by structural, aerospace, and pressure equipment standards requiring rigorous certification and traceability.

H2.4: Processing & Fabrication Implications

- Forming:

- 5052: Excellent cold formability (especially H32 temper). Ideal for deep drawing, bending, spinning. Minimal springback. Preferred for complex sheet metal parts.

- 6061: Good formability in annealed (O) temper. Cannot be cold formed effectively in T4 or T6 tempers (high risk of cracking). Requires solution heat treatment after forming if final properties are needed.

- Machining:

- 5052: Good machinability, produces fine chips. Slightly “gummier” than 6061.

- 6061: Excellent machinability, especially T6 temper. Produces clean chips. Preferred for complex machined parts.

- Welding:

- 5052: Weldable by common techniques (GTAW/TIG, GMAW/MIG). Use 5xxx series filler (5356, 5556). Critical: Susceptible to stress corrosion cracking (SCC) in the H116/H343 tempers if welded; H32 is preferred for weldability. Avoid 4xxx fillers (risk of hot cracking).

- 6061: Weldable by common techniques. Use 4xxx (4043, 4047) or 5xxx (5356) fillers. Critical: Welding significantly reduces strength in the Heat-Affected Zone (HAZ) of T6 material. Post-weld heat treatment (PWHT) is often required for critical structural applications (complex process). 4043 is common but lower strength; 5356 offers higher strength but higher cracking risk on thick sections.

- Heat Treatment:

- 5052: Work-hardened (H tempers). Cannot be strengthened by heat treatment. Annealing possible but rare.

- 6061: Precipitation-hardened (T tempers). Requires solution heat treatment and artificial aging (T6). This adds complexity, cost, and potential for distortion.

Key Processing Takeaway: 5052 excels in cold forming; avoid welding H116/H343. 6061 machines superbly but cannot be cold formed in T4/T6; welding requires careful filler selection and often PWHT for full strength, adding significant processing complexity and cost.

H2.5: Summary & Selection Guidance

| Feature | 5052 Aluminum | 6061 Aluminum |

| :————— | :—————————– | :——————————– |

| Best For Logistics | Sheet/plate supply; standard forms | Extrusions, bars, forgings; versatile forms |

| Critical Compliance | Marine/Chemical rules; Welding (Filler, SCC) | Structural/Aerospace codes; Welding (HAZ strength, PWHT); Pressure Vessels |

| Key Processing | Excellent Cold Forming; Weldable (H32 + 5xxx filler) | Excellent Machining; No Cold Forming (T4/T6); Weldable (PWHT often needed) |

| Heat Treat | Work-Hardened (H) only | Heat-Treatable (T – T6 common) |

| Primary Risk | SCC in welded & sensitized tempers | HAZ weakness after welding; Distortion during HT |

Choose 5052 when: Logistics prioritize readily available sheet/plate, and the application demands excellent formability, good corrosion resistance (especially marine), and welding of H32 temper material without the need for final heat treatment.

Choose 6061 when: Logistics require complex extrusions, bars, or forgings, and the application demands high strength (T6), excellent machinability, and can accommodate the complexities of heat treatment and potential post-weld heat treatment requirements for structural integrity.

Conclusion: Sourcing 5052 vs. 6061 Aluminum

When deciding between sourcing 5052 and 6061 aluminum, the choice ultimately depends on the specific requirements of the application.

5052 aluminum excels in environments requiring high corrosion resistance, excellent workability, and superior weldability. It is ideal for marine applications, chemical containers, and sheet metal forming due to its excellent fatigue strength and non-heat-treatable nature. However, it offers lower mechanical strength compared to heat-treatable alloys.

6061 aluminum, on the other hand, is a heat-treatable alloy known for its high strength-to-weight ratio, good machinability, and versatility. It is widely used in structural, aerospace, and automotive applications where strength and durability are critical. While it has good corrosion resistance, it is generally less corrosion-resistant than 5052 unless properly anodized or coated.

In summary:

– Choose 5052 for applications prioritizing formability, weldability, and corrosion resistance in harsh environments.

– Choose 6061 when higher strength, machinability, and structural performance are needed, especially in load-bearing or precision components.

Sourcing decisions should consider not only material properties but also availability, cost, fabrication methods, and end-use conditions to ensure optimal performance and cost-efficiency.