The global 3D printing market is experiencing robust expansion, driven by advancements in additive manufacturing technologies and growing demand for customized, on-demand production across industries such as fashion, electronics, and industrial design. According to Mordor Intelligence, the 3D printing market is projected to grow at a CAGR of over 20% from 2023 to 2028, with increasing adoption in both prototyping and end-part manufacturing. A key niche within this upward trend is the production of 3D printed buttons—offering design flexibility, rapid prototyping, and low-volume customization unattainable through traditional molding methods. As brands prioritize sustainability, reduce tooling costs, and respond to fast-changing design trends, the demand for specialized 3D printed fasteners and accessories continues to rise. This momentum has catalyzed the emergence of innovative manufacturers leveraging materials like durable resins, bioplastics, and nylon to deliver high-precision, aesthetically diverse buttons for apparel, tech wearables, and smart devices. The following list highlights the top 10 manufacturers at the forefront of this transformation, combining technological expertise, scalability, and design innovation to lead the next generation of button manufacturing.

Top 10 3D Printed Buttons Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial 3D Printing & 3D Printer Manufacturer

Domain Est. 2003

Website: voxeljet.com

Key Highlights: The experts in 3D printing systems: voxeljet is a leading industrial 3D printing company and 3D printer manufacturer and supplier….

#2 Incodema 3D

Domain Est. 2013

Website: incodema3d.com

Key Highlights: We focus on innovative additive manufacturing technology in support of aerospace, defense, and other industrial applications….

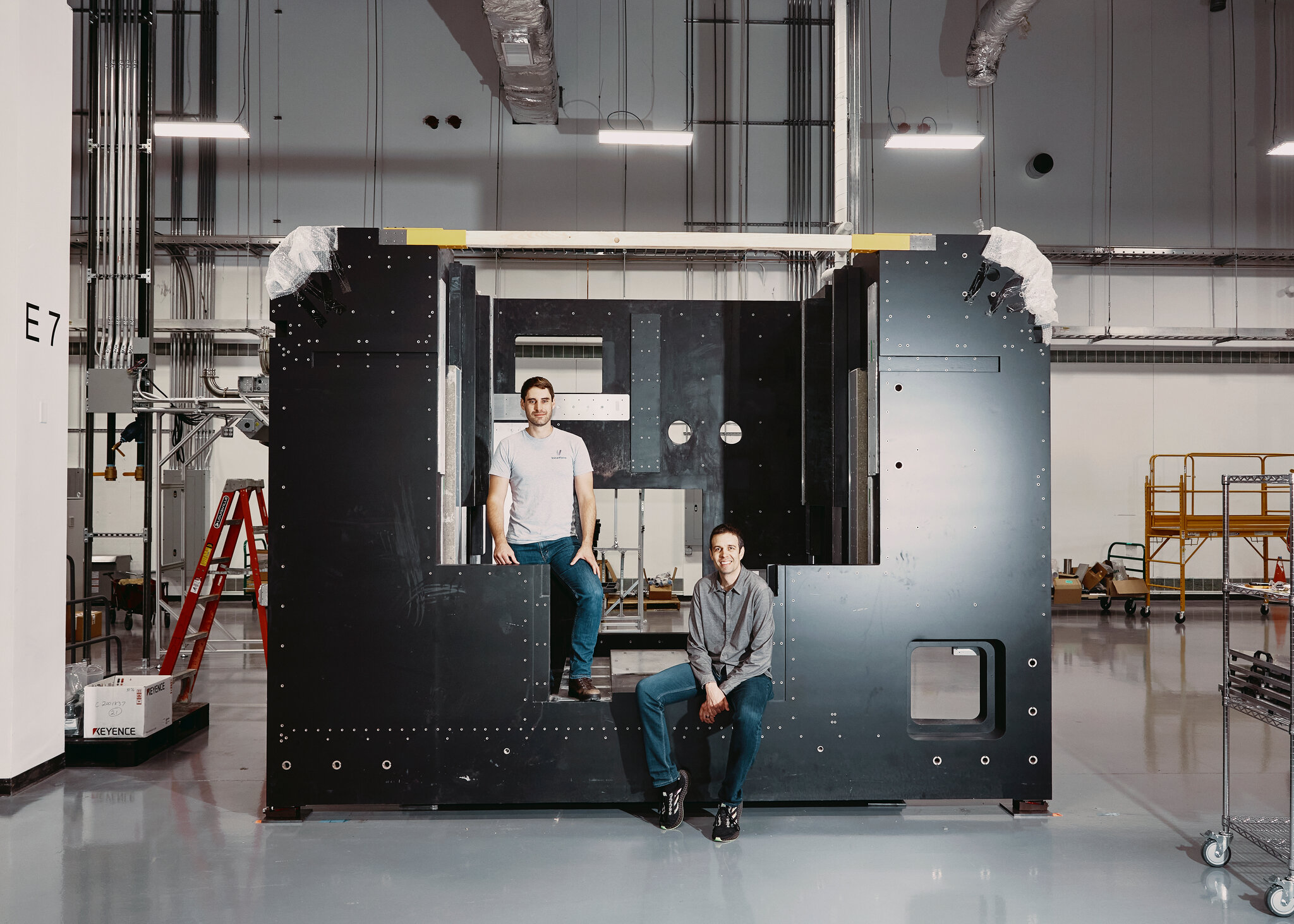

#3 AON3D

Domain Est. 2015

Website: aon3d.com

Key Highlights: A production-ready 3D printer for manufacturing full-scale, end-use parts in high performance polymers, such as PEEK and ULTEM™. Unrivaled Part Performance ……

#4 3D Systems

Domain Est. 1996

Website: 3dsystems.com

Key Highlights: 3D Systems provides comprehensive products and services, including 3D printers, print materials, software, on-demand manufacturing services, and healthcare ……

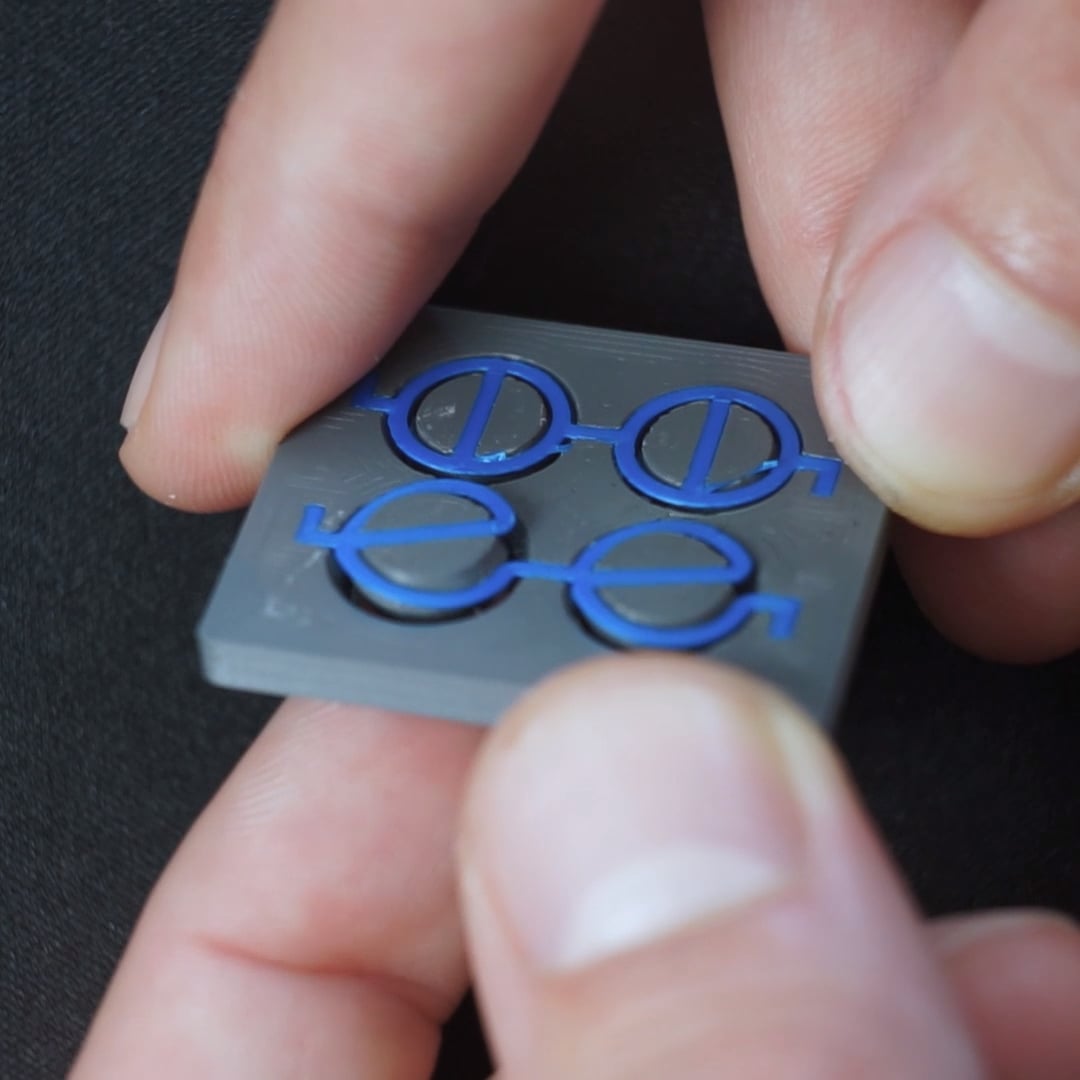

#5 reBUTTON Launches on Kickstarter

Domain Est. 1999

Website: 3dprint.com

Key Highlights: A new company called reBUTTON, based out of Houston, Texas, and founded by a man named Anthony Obodoechina, has abruptly emerged on the scene via a Kickstarter ……

#6 DyeMansion: Leading 3D Printing Post

Domain Est. 2009

Website: dyemansion.com

Key Highlights: We are the global leader in offering complete, connected & fully integrated end-to-end solutions for all finishing steps for 3D-printed polymer parts….

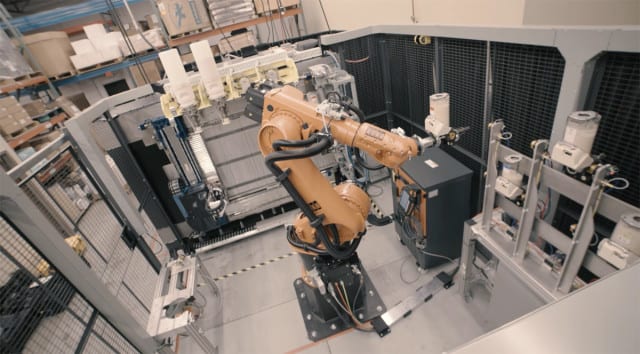

#7 High-Volume Automated 3D Printing

Domain Est. 2015

Website: mosaicmfg.com

Key Highlights: Unlock customization at scale with Mosaic’s additive manufacturing solution that’s built for flexibility. Seamlessly produce high-mix, low-volume parts in a ……

#8 unspun

Domain Est. 2017

Website: unspun.io

Key Highlights: Your future supply chain is—fast, local, and automated. Explore our software and hardware solutions for smarter apparel and textile production with 3D ……

#9 Mantle 3D

Domain Est. 2019

Website: mantle3d.com

Key Highlights: Mantle combines trusted CNC machining with 3D printing of industry-standard tool steels to produce precision tooling with the accuracy, surface finish, and ……

#10 EOS GmbH: Professional 3D Printing Solutions

Website: eos.info

Key Highlights: EOS is the world’s leading provider of 3D printing solutions, offering professional 3D printers, materials and software from a single source….

Expert Sourcing Insights for 3D Printed Buttons

H2: Emerging Market Trends in 3D Printed Buttons (2026 Outlook)

The 3D printed buttons market is poised for significant transformation by 2026, driven by advances in additive manufacturing, rising demand for customization, and growing sustainability initiatives across fashion and industrial sectors. As digital fabrication becomes more accessible and cost-effective, several key trends are expected to shape the landscape of 3D printed buttons over the next few years.

-

Customization and Personalization Surge

By 2026, the demand for highly personalized apparel and accessories is expected to drive widespread adoption of 3D printed buttons. Consumers and designers alike are seeking unique, limited-edition, or bespoke fashion elements, and 3D printing enables rapid prototyping and on-demand production of custom button designs. From monogrammed buttons to artist collaborations, the ability to produce small batches economically will make 3D printed buttons a staple in niche and luxury fashion markets. -

Integration with Smart Textiles and Wearables

The convergence of 3D printing with smart materials is opening new frontiers. By 2026, expect to see functional buttons that integrate conductive filaments or embedded microelectronics, serving as tactile interfaces for wearable technology. These “smart buttons” could act as switches for heated garments, fitness trackers, or even health-monitoring wearables, bridging aesthetics with utility in fashion-tech applications. -

Sustainable and Biodegradable Materials Adoption

Environmental concerns are pushing the fashion industry toward eco-friendly alternatives. 3D printed buttons offer a sustainable edge due to reduced material waste and the use of biodegradable or recycled filaments such as PLA, algae-based polymers, or recycled PETG. By 2026, brands emphasizing circularity and low carbon footprints are likely to adopt 3D printed buttons as part of their sustainability commitments, especially in fast-fashion and eco-conscious apparel segments. -

On-Demand and Localized Manufacturing Growth

3D printing enables decentralized production, reducing reliance on global supply chains. By 2026, more fashion brands are expected to adopt localized, on-demand manufacturing models using in-house or regional 3D printing hubs. This shift will reduce lead times, inventory waste, and shipping emissions, with buttons printed as needed for specific garment runs or customer orders. -

Expansion Beyond Fashion into Industrial and Medical Applications

While fashion remains a primary market, 3D printed buttons are finding utility in industrial controls, medical devices, and assistive technologies. Custom ergonomic buttons for prosthetics, tactile aids for the visually impaired, or durable control interfaces for machinery are emerging use cases. These applications benefit from the design flexibility and rapid iteration that 3D printing offers. -

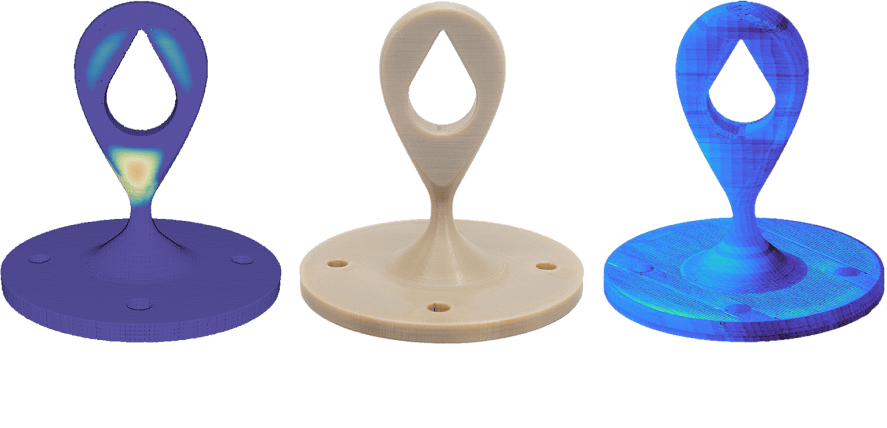

Improved Print Resolution and Material Diversity

Technological advancements in resin-based and multi-material 3D printing will enhance the aesthetic and functional quality of printed buttons. By 2026, manufacturers will leverage high-resolution printing to achieve intricate textures, vibrant colors, and durable finishes—making 3D printed buttons indistinguishable from traditionally manufactured counterparts while offering greater design freedom. -

Growth in B2B and Designer Toolkits

Platforms offering 3D printable button design software and cloud-based customization tools are expected to grow. By 2026, designers and small brands will have access to intuitive digital marketplaces where they can design, preview, and order 3D printed buttons seamlessly, accelerating innovation and lowering entry barriers.

In conclusion, the 3D printed buttons market in 2026 will be defined by personalization, sustainability, and digital integration. As additive manufacturing matures, 3D printed buttons will transition from a novelty to a mainstream component across fashion, technology, and industrial sectors, supported by evolving consumer preferences and technological capabilities.

Common Pitfalls When Sourcing 3D Printed Buttons: Quality and Intellectual Property Risks

Sourcing 3D printed buttons offers customization and rapid prototyping advantages, but it also introduces specific challenges related to quality consistency and intellectual property (IP) protection. Overlooking these pitfalls can lead to product failures, legal disputes, and reputational damage.

Quality Inconsistencies and Material Limitations

One of the primary challenges in sourcing 3D printed buttons is ensuring consistent quality across production runs. Unlike traditional manufacturing methods such as injection molding, 3D printing—especially with technologies like Fused Deposition Modeling (FDM) or Stereolithography (SLA)—can produce variable results due to differences in printer calibration, layer adhesion, and post-processing techniques. Factors like warping, surface roughness, and dimensional inaccuracies may affect button fit and functionality, particularly in high-use applications. Additionally, the mechanical properties of 3D printed materials (e.g., brittleness, UV sensitivity, or wear resistance) may not match industrial standards, leading to premature failure. Without rigorous quality control protocols and material certifications from suppliers, businesses risk receiving subpar components unsuitable for end-use.

Intellectual Property Infringement and Design Theft

Sourcing 3D printed buttons also raises significant intellectual property concerns. Digital design files (e.g., STL or OBJ formats) are easily shared and replicated, increasing the risk of unauthorized use or counterfeiting. If a supplier lacks robust IP safeguards, your proprietary button designs could be copied or sold to competitors. Conversely, using a 3D printing service that unknowingly produces buttons based on copyrighted or trademarked designs—such as branded shapes, logos, or patented mechanisms—can expose your company to infringement claims. It’s critical to establish clear contractual terms regarding design ownership, usage rights, and confidentiality, and to verify that the supplier conducts due diligence on design legality before production.

Logistics & Compliance Guide for 3D Printed Buttons

Product Classification & Regulatory Overview

3D printed buttons are generally classified as textile accessories or general consumer products, depending on their end-use (e.g., apparel, industrial gear, or novelty items). While they are typically low-risk, compliance with regional safety and labeling requirements is essential. Buttons intended for children’s clothing may fall under stricter regulations, such as the U.S. Consumer Product Safety Improvement Act (CPSIA) or EU REACH and Toy Safety Directive. Ensure materials used are non-toxic and free from restricted substances.

Material Compliance & Safety Standards

All 3D printing materials (e.g., PLA, ABS, PETG, TPU) must comply with relevant chemical safety regulations. In the EU, adherence to REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) is mandatory. In the U.S., materials should meet CPSIA requirements if used in children’s products, particularly regarding lead and phthalate content. Provide material safety data sheets (MSDS) and ensure suppliers certify compliance.

Labeling & Packaging Requirements

Buttons must be labeled according to destination market rules. Include:

– Manufacturer or importer name and address

– Country of origin

– Material composition (e.g., “3D Printed PLA”)

– Compliance marks (e.g., CE mark for EU, CPC for U.S. consumer products, if applicable)

Packaging should be durable, minimize environmental impact, and include any required warnings (e.g., “Not for children under 3” if small parts are a choking hazard).

Import/Export Documentation

For international shipping, prepare:

– Commercial invoice detailing product description, value, material, and quantity

– Packing list

– Certificate of Origin

– Material compliance certificates (e.g., REACH, RoHS, CPSIA)

– Harmonized System (HS) code—typically under 9606.22 (plastic buttons) or 6307.90 (other made-up clothing accessories), depending on composition and use

Verify import duties and restrictions with local customs authorities.

Shipping & Logistics Considerations

Due to their small size and lightweight nature, 3D printed buttons are suitable for standard parcel shipping. Use anti-static or padded packaging to prevent damage and static buildup. For bulk shipments, optimize packaging to reduce dimensional weight. Consider on-demand manufacturing near target markets to reduce shipping times and carbon footprint.

Intellectual Property & Design Rights

Ensure button designs do not infringe on existing trademarks, copyrights, or design patents. Custom designs should be original or properly licensed. If producing branded buttons, obtain written authorization from the brand owner. Maintain records of design ownership and usage rights.

Environmental & Sustainability Compliance

Use recyclable or biodegradable materials where possible (e.g., PLA from renewable resources). Dispose of failed prints and support material according to local waste regulations. Comply with Extended Producer Responsibility (EPR) schemes in regions like the EU, which may require registration and reporting for plastic products.

Quality Control & Traceability

Implement batch tracking for materials and finished buttons. Conduct regular inspections for dimensional accuracy, surface finish, and structural integrity. Retain production records (e.g., print settings, material lots) to support traceability in case of recalls or compliance audits.

End-Use & Industry-Specific Requirements

Buttons used in regulated industries (e.g., medical uniforms, military gear, or aviation) may require additional certifications (e.g., flame resistance, durability testing). Confirm end-use specifications with customers and validate performance through testing if needed.

Summary

Successfully distributing 3D printed buttons globally requires attention to material safety, accurate labeling, proper documentation, and adherence to regional regulations. Proactive compliance minimizes delays, avoids penalties, and supports sustainable, scalable operations.

In conclusion, sourcing 3D printed buttons offers a versatile, cost-effective, and highly customizable solution for prototypes, small-batch production, or niche design applications. The ability to rapidly iterate designs, experiment with unique shapes, textures, and personalized features makes 3D printing ideal for creators, fashion designers, and entrepreneurs seeking innovation and sustainability. While traditional manufacturing may be more efficient for large volumes, 3D printing excels in flexibility, reduced waste, and on-demand production. By partnering with reliable 3D printing services or investing in in-house capabilities, businesses and individuals can leverage this technology to bring creative button designs to life efficiently and sustainably.