The global demand for reliable and standardized power supply cords, including 3-prong configurations, continues to rise in tandem with the proliferation of electronic devices across consumer, industrial, and commercial sectors. According to a 2023 report by Mordor Intelligence, the global power cords and cables market is projected to grow at a CAGR of over 7.2% from 2023 to 2028, driven by increasing energy infrastructure investments and the expansion of IT and telecommunications industries. Similarly, Grand View Research estimated in 2022 that the worldwide power cable market size was valued at USD 26.8 billion and is expected to expand at a CAGR of 6.9% through 2030. With safety, durability, and compliance playing critical roles in product selection, sourcing partners are increasingly turning to specialized 3-prong power supply cord manufacturers that meet international standards such as UL, CE, and RoHS. As demand intensifies, identifying top-tier manufacturers becomes essential for OEMs and procurement teams aiming to balance performance, cost, and supply chain resilience.

Top 10 3 Prong Power Supply Cord Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quail Electronics Inc. ®

Domain Est. 1996

Website: quail.com

Key Highlights: Quail Electronics, Inc. is a leading manufacturer and supplier for a wide range of North American power cords. NEMA cables follow standards set by the ……

#2 Power Cord Sets, Power Cords and Jumper Cords

Domain Est. 1993

Website: volex.com

Key Highlights: Volex is a leading global manufacturer and supplier of power cord sets, power cords and jumper cords….

#3 Power Cord Manufacturer • Custom & Standard

Domain Est. 1997

Website: conwire.com

Key Highlights: We offer a comprehensive selection of high-quality power supply and retractile cords to meet the demands of numerous electronic applications….

#4 Prime Wire & Cable Inc.

Domain Est. 1998

Website: primewirecable.com

Key Highlights: Prime Wire & Cable provides indoor & outdoor cords, surge protectors & power strips , timers & remotes, lighting & related accessories. Prime Wire & Cable ……

#5 Power Cord & Electrical Cords

Domain Est. 1999

Website: americord.com

Key Highlights: Free delivery 30-day returnsWe offer a wide variety of power cords online, ranging from electronics power cords to cords for industrial machinery and everything in between….

#6 Power Cord Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: Our line of products include wiring harnesses, Coiled cords, extension cords, processed wires, high voltage twist lock cords, and more….

#7 Power Cords

Domain Est. 2018

Website: ecmfg.com

Key Highlights: We are a leading custom power cord manufacturer, providing design capabilities that meet or exceed all safety and operation standards….

#8 Power Cord Manufacturers

Domain Est. 2019

Website: powercordmanufacturers.com

Key Highlights: We specialize in designing and manufacturing power cords, cord sets, and … Copper is the standard choice for conductive wire in cord sets, a practice ……

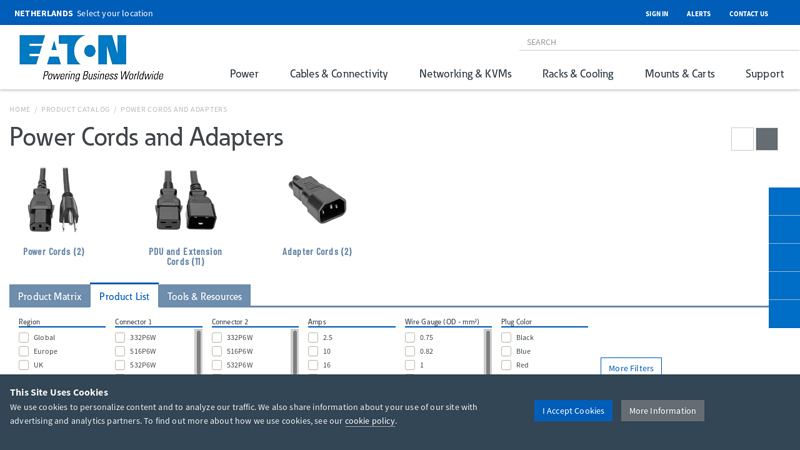

#9 Power Cords and Adapters

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: We offer AC power cords, extension cords, splitters and adapters for computers, servers and PDUs. Our cords have innovative features like coiled cords and ……

#10 StayOnline

Domain Est. 1996

Expert Sourcing Insights for 3 Prong Power Supply Cord

H2: 2026 Market Trends for 3 Prong Power Supply Cords

The global market for 3 prong power supply cords is poised for steady evolution by 2026, shaped by technological advancements, regulatory shifts, and changing consumer demands across residential, commercial, and industrial sectors. As a foundational component in electrical connectivity, these cords—featuring hot, neutral, and grounding conductors—are critical for safe power delivery in a wide array of devices, from household appliances to IT equipment and industrial machinery. The following analysis outlines key trends expected to influence the 3 prong power supply cord market through 2026.

-

Increased Emphasis on Safety and Compliance

By 2026, regulatory standards such as UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and regional electrical codes are anticipated to become more stringent, especially in North America and Europe. The third prong, serving as a grounding mechanism, will remain essential in meeting safety requirements. Growing awareness of electrical hazards and surge protection will drive demand for certified, high-quality cords that comply with updated safety norms, particularly in healthcare, education, and consumer electronics applications. -

Growth in Consumer Electronics and Remote Work Infrastructure

The proliferation of home offices, data centers, and remote work setups continues to fuel demand for reliable power solutions. Devices such as desktop computers, monitors, printers, and network equipment predominantly use 3 prong cords for stable and grounded power. As hybrid work models persist into 2026, the need for durable, tangle-resistant, and longer-length power cords will rise, supporting market expansion. -

Sustainability and Eco-Friendly Materials

Environmental regulations and corporate sustainability goals are pushing manufacturers toward greener alternatives. By 2026, there will be a noticeable shift toward power cords made with low-halogen, recyclable, or bio-based insulation materials. Companies may increasingly adopt eco-labeling and lifecycle assessments to appeal to environmentally conscious buyers, particularly in Europe and North America. -

Integration with Smart and Energy-Efficient Systems

While the 3 prong cord itself remains a passive component, its role in smart power strips, surge protectors, and IoT-enabled energy management systems is expanding. These intelligent systems often require grounded connections for safe operation. As smart home and building automation markets grow, so will the demand for reliable 3 prong cords that support advanced power distribution units and energy monitoring devices. -

Regional Market Dynamics

North America will remain a dominant market due to legacy electrical infrastructure and strict grounding requirements. Asia-Pacific, particularly China and India, will experience increased demand driven by urbanization, rising disposable incomes, and expanding electronics manufacturing. However, regional variations in plug types (e.g., NEMA 5-15 in the U.S. vs. IEC 60320 in international markets) will necessitate customization, creating opportunities for modular or region-specific cord designs. -

Supply Chain Resilience and Localization

Following disruptions from global events in prior years, manufacturers are expected to localize production and diversify sourcing of raw materials (e.g., copper, PVC, rubber) by 2026. This trend will enhance supply chain resilience and reduce lead times, particularly for OEMs in appliance and industrial equipment sectors reliant on consistent cord supply. -

Competition from Alternative Technologies

Although wireless power and USB-C PD (Power Delivery) are gaining traction for low-power devices, they are unlikely to displace 3 prong cords for high-wattage applications. Instead, coexistence is expected, with 3 prong cords maintaining dominance in high-power and safety-critical environments. Innovation will focus on hybrid solutions—such as cords with built-in surge protection or EMI filtering—rather than outright replacement.

Conclusion

By 2026, the 3 prong power supply cord market will remain robust, underpinned by enduring safety standards and the growing electrification of everyday life. While incremental innovations in materials, design, and integration with smart systems will shape product evolution, the core function of safe, grounded power delivery will ensure continued relevance across global markets. Manufacturers who prioritize compliance, sustainability, and adaptability to regional needs will be best positioned to capture growth in this mature yet dynamic segment.

Common Pitfalls When Sourcing a 3-Prong Power Supply Cord (Quality, IP)

Sourcing a reliable 3-prong power supply cord—especially when considering quality and Ingress Protection (IP) ratings—can be fraught with challenges. Overlooking key factors may lead to safety hazards, premature failure, or non-compliance. Below are common pitfalls to avoid:

1. Prioritizing Cost Over Safety and Certification

One of the most frequent mistakes is choosing the lowest-priced option without verifying safety certifications. Cheap cords may lack essential approvals like UL, CE, CSA, or ETL, increasing fire or shock risks. Always confirm the cord meets regional safety standards and includes proper certification marks.

2. Misunderstanding IP Ratings and Environmental Suitability

Many buyers assume all 3-prong cords offer some level of water or dust resistance. However, standard power cords often have no IP rating (IP00), meaning they’re not protected against solids or liquids. If the application involves moisture, dust, or outdoor use, selecting a cord with an appropriate IP rating (e.g., IP67 for dust-tight and water immersion) is crucial. Always match the IP rating to the environment to prevent damage or electrical hazards.

3. Overlooking Cable Gauge and Current Rating

Using undersized wiring (e.g., 18 AWG instead of 16 or 14 AWG) for high-power devices can lead to overheating, voltage drop, and fire risk. Ensure the cord’s gauge and current rating match the load requirements. For heavy-duty applications, verify that both the plug and receptacle are rated for the intended amperage and voltage.

4. Assuming All 3-Prong Cords Are Interchangeable

Not all NEMA 5-15P or IEC 60320 connectors are equal in build quality. Differences in plug materials, strain relief, and internal soldering can impact durability. Poor strain relief leads to broken wires near the plug, a common failure point. Inspect samples for robust construction and secure wire anchoring.

5. Neglecting Cord Jacket Material and Flexibility

The outer jacket material affects performance in different environments. PVC jackets may crack in cold temperatures or under UV exposure. For industrial or outdoor use, consider more durable materials like rubber, neoprene, or thermoplastic elastomer (TPE), which offer better flexibility and resistance to oils, abrasion, and weather.

6. Failing to Verify Authenticity and Supplier Reliability

Counterfeit or misrepresented products are common in online marketplaces. Suppliers may falsely claim certifications or IP ratings. Work with reputable vendors, request test reports, and perform spot checks. Third-party testing can verify claims about insulation thickness, flame resistance, and IP compliance.

7. Ignoring Application-Specific Requirements

Using a general-purpose cord in medical, industrial, or data center environments risks non-compliance with industry regulations. Some applications require low-leakage cords, shielded cables, or specific flame ratings (e.g., UL 1581 VW-1). Always assess the full operating context before sourcing.

Avoiding these pitfalls ensures safer, longer-lasting performance and compliance with technical and regulatory standards.

Logistics & Compliance Guide for 3 Prong Power Supply Cord

Overview

This guide outlines the essential logistics and compliance requirements for the import, distribution, and use of a 3 prong power supply cord (typically NEMA 5-15P to IEC 60320 C13/C15). Adhering to these standards ensures product safety, regulatory compliance, and smooth supply chain operations.

Regulatory Compliance

Electrical Safety Standards

– UL Certification (USA): The cord must be certified to UL 817 (Standard for Power Supply Cords) and bear a UL Listed mark.

– CSA Certification (Canada): Compliance with CSA C22.2 No. 21 is required for sale in Canada; look for the CSA mark.

– CE Marking (Europe): Must meet Low Voltage Directive (LVD) 2014/35/EU and RoHS 2011/65/EU. Typically evaluated under EN 50525 or EN 60204-1.

– UKCA Marking (UK): Post-Brexit, UKCA replaces CE for Great Britain; compliance with UK standards equivalent to CE is required.

Plug and Socket Compatibility

– NEMA 5-15P Plug: Designed for 125V, 15A grounded outlets (common in North America).

– Grounding Requirement: The third prong provides grounding and must be continuously bonded to ensure user safety.

– IEC Connector (e.g., C13/C15): Must match the mating inlet on the equipment; C13 for up to 120°C, C15 for higher temperatures.

Environmental & Material Compliance

– RoHS (Restriction of Hazardous Substances): Restricts lead, mercury, cadmium, and other harmful materials.

– REACH (EU): Requires disclosure of Substances of Very High Concern (SVHCs); applicable for EU shipments.

– California Prop 65: Warns of potential exposure to listed chemicals (e.g., phthalates in PVC insulation).

Logistics Considerations

Packaging & Labeling

– Secure Packaging: Use anti-static or protective packaging to prevent damage during transit.

– Labeling Requirements: Include product type, voltage/current rating (e.g., 125V 10A), manufacturer, country of origin, and compliance marks (UL, CSA, CE).

– Multi-language Labels: For international distribution, include safety warnings in local languages.

Shipping & Handling

– Weight & Dimensions: Typical 3 prong cords are lightweight (under 1 lb) and compact; optimize for small parcel or bulk shipment.

– Hazard Classification: Not classified as hazardous goods under IATA/IMDG; standard shipping applies.

– Storage Conditions: Store in dry, ambient conditions (5°C–40°C); avoid UV exposure and extreme temperatures.

Customs & Import Documentation

– HS Code: Commonly classified under 8544.42 (Insulated electric conductors, with connectors). Confirm locally.

– Required Documents: Commercial invoice, packing list, certificate of compliance (e.g., UL test report), and bill of lading.

– Duties & Tariffs: Vary by country; check local tariff schedules (e.g., HTSUS in the U.S.).

Quality & Testing

Mandatory Testing

– Electrical Tests: Dielectric withstand (hi-pot), continuity, insulation resistance.

– Mechanical Tests: Cord retention (pull test), flex endurance (typically 10,000 cycles).

– Temperature Rise Test: Ensures no overheating under rated load.

Factory Audits & Certifications

– Conduct periodic audits of manufacturing facilities to ensure compliance with ISO 9001 and relevant safety standards.

– Maintain up-to-date test reports from accredited laboratories (e.g., UL, TÜV, Intertek).

End-of-Life & Sustainability

- Recycling: Power cords contain copper and plastic; encourage proper e-waste recycling.

- WEEE Compliance (EU): Producers may be responsible for collection and recycling under WEEE Directive 2012/19/EU.

Summary

Ensuring compliance with electrical safety, environmental regulations, and proper logistics handling is critical for a 3 prong power supply cord. Always verify certification marks, maintain proper documentation, and follow regional requirements to avoid delays or penalties.

In conclusion, sourcing a 3-prong power supply cord requires careful consideration of compatibility, safety standards, and quality. It is essential to verify the correct voltage, amperage, and plug configuration to ensure it meets the requirements of the equipment and complies with regional electrical codes. Opting for cords from reputable suppliers or manufacturers that adhere to safety certifications (such as UL, ETL, or CSA) helps ensure durability and reduces the risk of electrical hazards. Additionally, considering factors like cord length, gauge, and jacket material can enhance both functionality and longevity. By thoroughly evaluating these aspects, you can source a reliable and safe 3-prong power supply cord that supports efficient and secure operation of your devices.