The global market for agricultural and landscaping equipment continues to expand, driven by increasing demand for efficient land management solutions. According to Mordor Intelligence, the global agricultural machinery market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, fueled by rising mechanization in both developed and emerging economies. As land clearing becomes a critical step in agricultural expansion, forestry management, and urban development, specialized attachments like 3-point hitch stump grinders are seeing heightened adoption among contractors and landowners. These compact, tractor-mounted tools offer cost-effective and efficient solutions for removing tree stumps without the need for heavy, standalone machinery. With growing investment in land development and rural infrastructure, Grand View Research notes that the global landscaping equipment market is expected to register a CAGR of 4.8% from 2023 to 2030. This surge in demand has led to a competitive landscape among manufacturers innovating in durability, cutting efficiency, and compatibility across tractor models. In this report, we analyze the top nine manufacturers leading the 3-point hitch stump grinder segment, evaluating their market presence, technological advancements, and product performance based on sales data, customer reviews, and industry benchmarks.

Top 9 3 Point Hitch Stump Grinder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 StumpBuster

Domain Est. 1998

Website: shavermfg.com

Key Highlights: Shaver Manufacturing is a leading manufacturer of skid steer and 3-point hitch attachments. We manufacture a complete line of post drivers, post hole diggers, ……

#2 Stump Grinders for Tractors

Domain Est. 2015

#3 TSG50

Domain Est. 1998

Website: woodsequipment.com

Key Highlights: TSG50 ; Performance. Twenty-four tough, carbide steel teeth cut bidirectionally for increased productivity. Easily and efficiently grind tree stumps to mulch….

#4 3

Domain Est. 2002

Website: erskineattachments.com

Key Highlights: The 3-Point Stump Grinder is mean to the stump but kind to your tractor. Its heavy-duty stabilizer base allows for more efficient grinding performance….

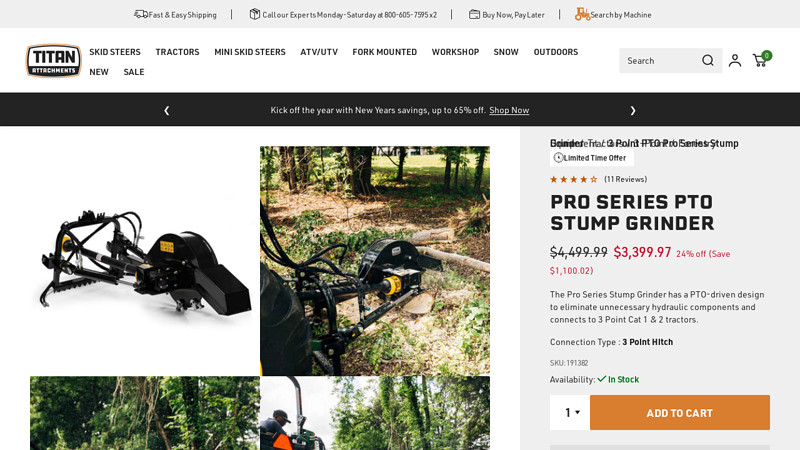

#5 3 Point PTO Pro Series Stump Grinder

Domain Est. 2002

Website: palletforks.com

Key Highlights: In stock Rating 4.0 (11) Remove tree stumps fast with the Pro Series Stump Grinder. This implement attaches to Cat 1 and 2 tractors with a 3 Point hitch for easy installation….

#6 3

Domain Est. 2003

Website: quickattach.com

Key Highlights: Rating 4.6 (23) · $299 delivery · 60-day returnsThe 3-Point Stump Grinder is mean to the stump but kind to your tractor. Its heavy-duty stabilizer base allows for more efficie…

#7 Stump Grinders

Domain Est. 2006

Website: woodlandmills.com

Key Highlights: Our rugged PTO-drive stump grinders are equipped with large diameter, dynamically balanced, solid steel grinding flywheels and resilient tungsten carbide ……

#8 PTO Stump Grinders for Compact Tractors – Heavy-Duty

Domain Est. 2021

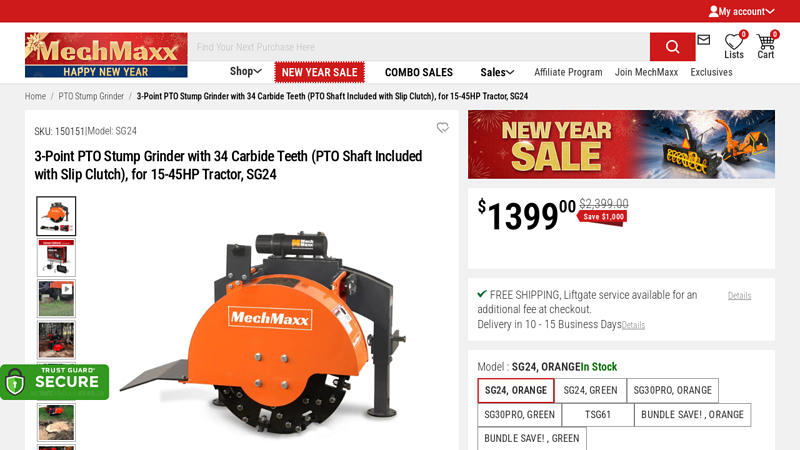

#9 MechMaxx 3

Domain Est. 2022

Website: mechmaxx.com

Key Highlights: In stock Rating 5.0 (27) Connects directly to your tractors 3 point hitch system and is equipped with a large 24” diameter solid steel grinding flywheel and 34 tungsten carbide …

Expert Sourcing Insights for 3 Point Hitch Stump Grinder

2026 Market Trends for 3 Point Hitch Stump Grinder

The 3 Point Hitch Stump Grinder market is poised for notable evolution by 2026, driven by advancements in agricultural and landscaping equipment, rising demand for efficient land clearing solutions, and increasing adoption among small to mid-sized landowners and contractors. This analysis explores key market trends shaping the industry in the coming years.

Growing Demand in Residential and Agricultural Sectors

A primary driver of the 2026 market outlook is the rising need for efficient land management tools in both residential and agricultural applications. As urban expansion continues and rural landowners seek to reclaim overgrown areas, the 3 point hitch stump grinder—compatible with widely available tractors—offers a cost-effective and versatile solution. The popularity of compact tractors among hobby farmers and suburban landowners is expected to boost demand, especially in North America and Europe.

Technological Advancements and Equipment Integration

By 2026, manufacturers are anticipated to integrate smart features such as improved blade durability, vibration reduction systems, and compatibility with precision farming technology. Enhanced hydraulic systems and quick-attach mechanisms will further streamline operations, reducing labor intensity and increasing productivity. These innovations will appeal to professional landscapers and municipal maintenance crews seeking reliable, high-performance equipment.

Emphasis on Sustainability and Fuel Efficiency

Environmental regulations and consumer preferences are pushing manufacturers toward more sustainable designs. The 2026 market will likely see a rise in stump grinders optimized for fuel efficiency, with some models exploring hybrid or electric auxiliary power systems. This shift aligns with broader trends in outdoor power equipment, where reduced emissions and noise levels are becoming competitive advantages.

Expansion of Online Sales and Rental Markets

E-commerce platforms and equipment rental services are expected to play a larger role in market accessibility by 2026. Online marketplaces enable easier comparison and purchase of 3 point hitch stump grinders, while rental programs lower entry barriers for occasional users. This trend supports market penetration in emerging regions and among DIY users who may not justify a full purchase.

Regional Market Dynamics

North America remains the dominant market due to widespread tractor ownership and active land development. However, growth in Latin America, Eastern Europe, and parts of Asia-Pacific is forecasted, fueled by agricultural modernization and infrastructure projects. Localized manufacturing and distribution partnerships will be key for companies aiming to capture emerging market share.

In conclusion, the 2026 outlook for 3 Point Hitch Stump Grinders reflects a market shaped by innovation, accessibility, and sustainability. As user needs diversify and technology advances, manufacturers who adapt to these trends will be well-positioned for growth.

Common Pitfalls When Sourcing a 3 Point Hitch Stump Grinder (Quality, IP)

Sourcing a 3 Point Hitch Stump Grinder involves several risks, particularly concerning product quality and intellectual property (IP) protection. Understanding these pitfalls helps ensure a reliable, legal, and cost-effective purchase.

Poor Build Quality and Materials

Many low-cost stump grinders, especially those from less-regulated manufacturers, use substandard steel, inadequate welding, or inferior bearings and blades. This leads to premature wear, frequent breakdowns, and safety hazards. Buyers may overlook certifications or fail to verify material specifications, resulting in equipment that cannot withstand heavy-duty use.

Lack of Quality Control Processes

Suppliers without robust quality control (QC) systems may deliver inconsistent products. Without third-party inspections or documented QC procedures, defects such as misaligned components or improper assembly can go unnoticed until after delivery, increasing downtime and repair costs.

Inadequate or Missing Safety Features

Some imported stump grinders lack essential safety guards, proper shielding, or vibration dampening systems. This not only increases the risk of operator injury but may also lead to non-compliance with OSHA or ANSI standards in the U.S., exposing buyers to liability.

Misrepresentation of Performance Specifications

Suppliers may exaggerate horsepower, cutting depth, or compatibility with tractor models. Without verified test reports or independent reviews, buyers risk purchasing equipment that underperforms or is incompatible with their existing machinery.

Intellectual Property (IP) Infringement Risks

A significant number of stump grinders on the market—especially from certain overseas manufacturers—copy patented designs, logos, or technical features from reputable brands. Sourcing such products can expose buyers to legal action, shipment seizures, or reputational damage, particularly if importing into markets with strong IP enforcement (e.g., the U.S. or EU).

No Warranty or After-Sales Support

Many low-cost suppliers do not offer warranties or lack accessible customer service. If a defect arises, replacement parts or technical assistance may be unavailable, leading to extended equipment downtime and higher total cost of ownership.

Counterfeit or Clone Products

Some sellers market stump grinders as “compatible with” or “inspired by” well-known brands, but these are often outright clones that infringe on design patents or trademarks. Buyers may unknowingly support IP theft, risking customs issues or legal consequences.

Failure to Verify Supplier Authenticity

Online marketplaces and intermediaries may list suppliers who are not the actual manufacturers. Without due diligence—such as onsite audits, business license verification, or reference checks—buyers may deal with brokers who lack accountability and traceability.

To mitigate these risks, conduct thorough supplier vetting, request product certifications, perform pre-shipment inspections, and consult legal experts when IP concerns arise. Investing in reputable brands or verified manufacturers ensures long-term reliability and compliance.

Logistics & Compliance Guide for 3 Point Hitch Stump Grinder

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient transport, operation, and maintenance of a 3 Point Hitch Stump Grinder. Adherence to these guidelines ensures operator safety, regulatory compliance, and optimal equipment performance.

Transportation & Handling

Proper transport and handling are critical to prevent damage to the stump grinder, your tractor, and surrounding property or personnel.

- Secure Attachment: Always ensure the stump grinder is securely fastened to the tractor’s Category 1, 2, or 3 three-point hitch system using the correct pins (e.g., clevis pins with R-clips or hitch pins). Verify all locking mechanisms are engaged before moving.

- Transport Position: Raise the stump grinder to its highest transport position using the tractor’s hydraulic lift system. This ensures maximum ground clearance and prevents accidental contact with obstacles.

- Blade Safety: Engage any provided blade brake or locking mechanism. If none exists, ensure the cutting disc is fully raised and secured, with the power take-off (PTO) shaft disengaged. Never transport with the disc spinning.

- PTO Shaft Handling: When detaching, shorten the PTO shaft to its minimum safe operating length. Use a support bracket or carrier to prevent the shaft from dragging on the ground during transport. Ensure universal joints are properly greased and not damaged.

- Load Securing (Trailering): If transporting the stump grinder on a trailer:

- Use robust chains or ratchet straps rated for the grinder’s weight, attached to designated lifting/towing points.

- Criss-cross straps from front to rear tie-down points on the trailer frame.

- Chock the trailer wheels.

- Cover the cutting disc with a heavy-duty protective guard if available.

- Route Planning: Avoid low bridges, overhanging branches, or narrow pathways. Be mindful of the increased overall height and width of the tractor-grinder combination.

Regulatory Compliance

Operating a stump grinder involves adherence to various safety and environmental regulations.

- Operator Training & Certification: While specific certification for stump grinders may not always be mandated like for aerial lifts, operators must be thoroughly trained by a qualified person on the specific model’s operation, safety procedures, and emergency protocols. Maintain training records.

- Personal Protective Equipment (PPE): Mandatory PPE includes:

- ANSI-approved safety glasses or a full-face shield.

- Hearing protection (earmuffs or plugs – PTO operation is loud).

- Heavy-duty work gloves.

- Steel-toed boots.

- Long pants and a long-sleeved shirt (avoid loose clothing).

- Machine Safety Standards: Ensure the grinder complies with relevant safety standards (e.g., ANSI B71.4 for landscape equipment, or applicable regional standards like CE marking in Europe). Verify the presence and functionality of:

- ROPS (Roll-Over Protective Structure) on the tractor.

- FOPS (Falling Object Protective Structure) on the tractor (if applicable).

- Functional PTO master shield and implement shield.

- Emergency stop mechanism (if equipped).

- Clear, legible warning labels and decals.

- Environmental Regulations:

- Debris Management: Chip wood debris responsibly. Do not leave large piles that could become fire hazards or harbor pests. Compost, chip for mulch, or dispose of at a designated facility per local regulations.

- Soil & Root Disturbance: Be aware of potential impacts on nearby plants, irrigation lines, or underground utilities (call 811/800 before digging near any utility lines).

- Dust Control: On dry, windy days, consider wetting the grinding area slightly to minimize dust, which can be a nuisance or health concern.

Operational Safety & Best Practices

Safe operation prevents accidents and extends equipment life.

- Pre-Operational Inspection: Conduct a thorough check before each use:

- Inspect the PTO shaft for damage, wear, or missing guards.

- Check the cutting disc for cracks, excessive wear, or missing carbide teeth. Replace if damaged.

- Ensure all bolts, nuts, and pins on the three-point hitch and grinder frame are tight.

- Verify hydraulic hoses (if applicable for wheel movement or depth control) are in good condition.

- Check fluid levels (tractor hydraulic, engine oil).

- Worksite Preparation:

- Clear the area of rocks, debris, metal (nails, wire), and other foreign objects that could become dangerous projectiles.

- Ensure bystanders, pets, and children are at a safe distance (at least 50 feet recommended).

- Identify the stump’s root system direction if possible.

- Safe Operation:

- Engage the PTO only when the tractor is at the correct operating RPM (as specified in the manual, usually mid-to-high throttle).

- Lower the grinder gently onto the stump using the tractor’s hydraulic controls. Apply steady, controlled pressure; do not force it.

- Overlap grinding passes slightly to ensure complete removal.

- Disengage the PTO before raising or lowering the grinder to a new position.

- Shut off the tractor engine before performing any maintenance, clearing jams, or inspecting the cutting disc closely.

- Maintenance & Storage:

- Follow the manufacturer’s maintenance schedule for lubricating bearings, checking belts (if applicable), and inspecting hydraulic components.

- Clean debris from the grinder after use.

- Store the grinder in a dry, secure location. Remove the PTO shaft if storing long-term to prevent stress.

- Sharpen or replace carbide teeth as per manufacturer guidelines.

By meticulously following this logistics and compliance guide, operators can ensure the safe, legal, and effective use of their 3 Point Hitch Stump Grinder. Always consult the specific operator’s manual provided with your equipment for the most accurate and model-specific instructions.

Conclusion for Sourcing a 3-Point Hitch Stump Grinder

After evaluating various options for sourcing a 3-point hitch stump grinder, it is clear that selecting the right equipment involves balancing performance, compatibility, durability, and cost. A 3-point hitch stump grinder offers excellent versatility and integration with compact tractors, making it an efficient solution for land clearing, stump removal, and property maintenance.

Key factors to consider when sourcing include:

– Compatibility with your tractor’s horsepower and hitch category (e.g., Category 1 or 2).

– Rotor design and cutting capacity, which directly impact grinding efficiency.

– Build quality and materials to ensure longevity, especially under heavy use.

– Brand reputation and warranty support for reliability and after-sales service.

– Price and availability, weighing new versus used or OEM versus aftermarket models.

Based on these criteria, purchasing from established agricultural or forestry equipment manufacturers—such as Land Pride, King Kutter, or Rhino Ag—provides a reliable balance of performance and support. Alternatively, reputable used equipment dealers or online marketplaces can offer cost-effective solutions if inspection and due diligence are performed.

In conclusion, investing in a quality 3-point hitch stump grinder enhances productivity and land management capabilities. Proper sourcing ensures a durable, efficient, and safe tool that integrates seamlessly with your existing equipment, delivering long-term value for agricultural, landscaping, or forestry operations.