The global CNC machine market is experiencing robust growth, driven by rising demand for precision manufacturing across aerospace, automotive, and industrial machinery sectors. According to Mordor Intelligence, the CNC Machine Market was valued at USD 74.39 billion in 2023 and is projected to reach USD 108.98 billion by 2029, growing at a CAGR of 6.58% during the forecast period. This sustained expansion has fueled not only new machine sales but also a surge in demand for high-quality second-hand CNC equipment, as cost-conscious manufacturers seek reliable, performance-proven alternatives. With machine longevity and technological resilience enabling extended operational lifespans, pre-owned CNC systems from established manufacturers offer significant value. As companies look to optimize capital expenditures without compromising on accuracy or efficiency, the market for used CNC machines has become increasingly strategic. In this context, identifying reputable second-hand CNC machine manufacturers—those known for durability, spare parts availability, and strong service networks—is critical. Based on market presence, resale value trends, and machine performance data, the following nine manufacturers consistently emerge as top choices in the pre-owned CNC space.

Top 9 2Nd Hand Cnc Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Used CNC Machines & New Mazak Machinery

Domain Est. 1991

Website: machsys.com

Key Highlights: Machinery Systems, Inc. is your complete source for new and used machining equipment and financing. Our passion for manufacturing drives us to engineer the best …Missing: 2nd ha…

#2 Resell CNC

Domain Est. 2008

Website: resellcnc.com

Key Highlights: Browse our huge selection of quality used CNC machines and used Haas and Mazak machines for sale from top manufacturers like Mazak, Haas, DMG, Okuma, ……

#3 CNC Machines

Domain Est. 1997

Website: cncmachines.com

Key Highlights: We have a wide selection of used CNC machines, starting from used CNC Mills, CNC Lathes and used fabrication equipment. We strive to become your primary source ……

#4 Used CNC LLC

Domain Est. 1997

Website: usedcnc.com

Key Highlights: Used CNC LLC brings 40+ years of expertise in buying, selling, and liquidating CNC machinery. Get top value and a hassle-free process for your used CNC ……

#5 CNC Machine Tools Distributor

Domain Est. 1997

Website: absolutemachine.com

Key Highlights: Absolute Machine Tools is a master importer and distributor of CNC machine tools throughout North America. Comprehensive Metal Cutting and Automation Products….

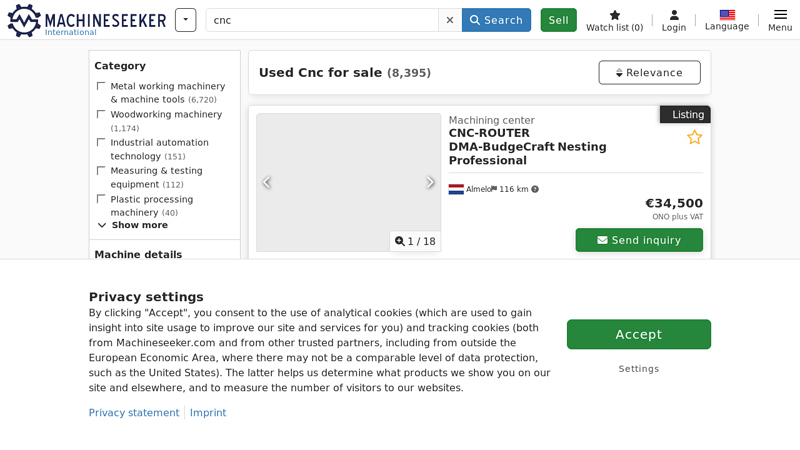

#6 Used Cnc for sale on Machineseeker.com

Domain Est. 1999

Website: machineseeker.com

Key Highlights: Used Cnc for sale on Machineseeker.com ✔️ great brands & offers available now ✔️ buy or sell Cnc on Machineseeker in the USA….

#7 Clark Machinery Sales

Domain Est. 2005

Website: clarkmachinerysales.com

Key Highlights: We specialize in late model, clean, used Haas, Doosan, Okuma and Citizen CNC machines. Our process protects both buyer and seller.Missing: 2nd hand…

#8 Used Machines

Domain Est. 2013

Website: en.dmgmori.com

Key Highlights: As the world´s largest dealer in used CNC machine tools – we are the number one partner for all options! Highlights. Sales, Buybacks or Trade-In from a ……

#9 Silverlight CNC

Domain Est. 2015

Website: silverlightcnc.com

Key Highlights: Silverlight CNC features a wide range of used machinery such as Boring Mills, CNC Drilling, CNC Turning and much more, from brands such as Ambar, Brother, …Missing: 2nd hand…

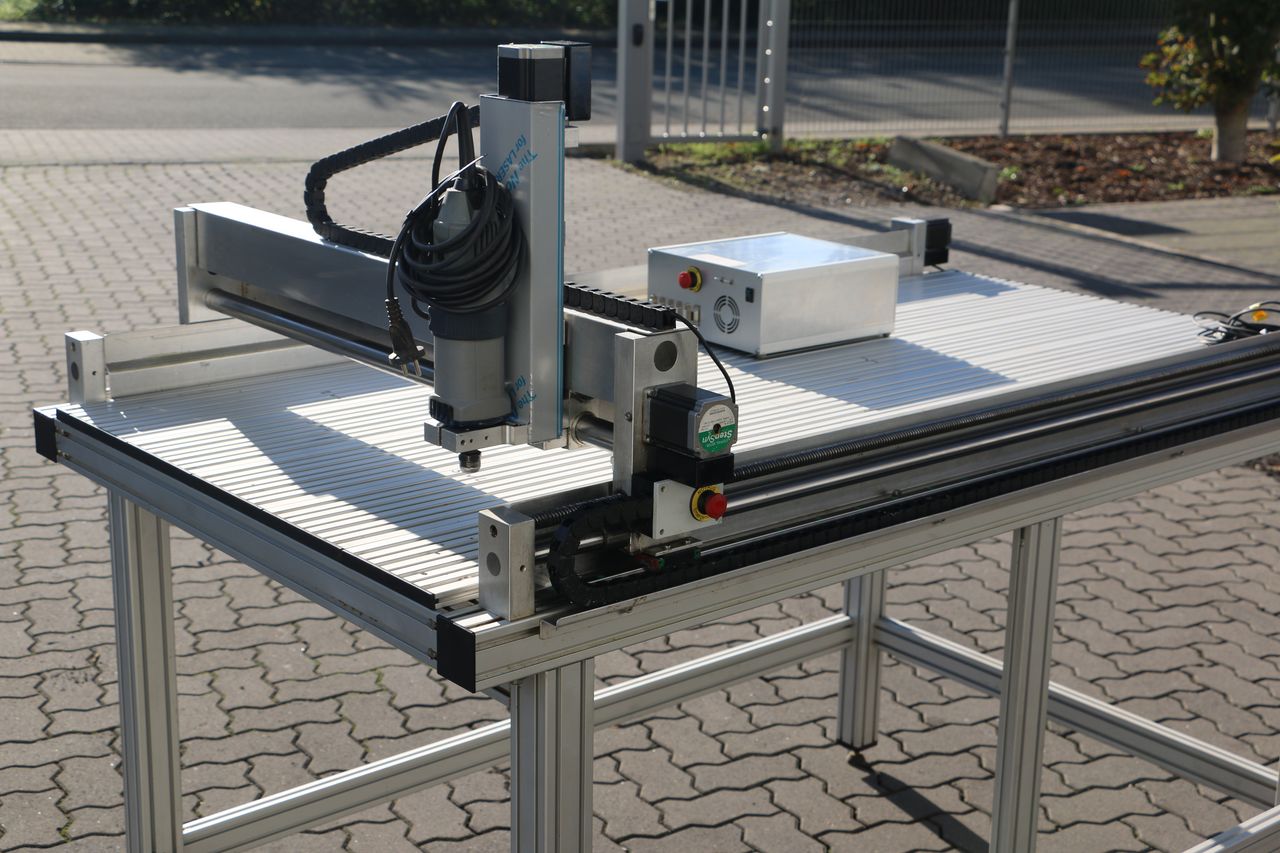

Expert Sourcing Insights for 2Nd Hand Cnc Machine

2026 Market Trends for Second-Hand CNC Machines

The market for second-hand CNC (Computer Numerical Control) machines is poised for significant evolution by 2026, driven by technological advancements, economic pressures, and shifting industrial demands. Key trends shaping this sector include:

Increased Demand Driven by Cost Efficiency and Accessibility

With rising capital expenditure constraints, especially among SMEs and startups, the cost-effectiveness of second-hand CNC machines will make them increasingly attractive. In 2026, buyers are expected to prioritize machines that offer a high return on investment, with reconditioned or refurbished CNC equipment providing near-new performance at a fraction of the cost. This trend will be amplified in emerging markets where access to new machinery remains limited.

Technological Obsolescence and Upgradability

As Industry 4.0 integration becomes standard, many older CNC machines will be retrofitted with smart controls, IoT connectivity, and improved software compatibility. By 2026, the resale value of second-hand machines will heavily depend on their upgradability. Machines that can accept modern control systems (e.g., retrofitting with Fanuc, Siemens, or Heidenhain controls) will dominate the used market, while obsolete models without upgrade paths may face depreciation.

Growth in Digital Marketplaces and Transparent Valuation

Online platforms specializing in used industrial machinery will gain prominence, offering enhanced search capabilities, machine history tracking, and remote diagnostics. Blockchain-based certification for machine usage and maintenance records may emerge, increasing transparency and trust. This digital transformation will streamline transactions and expand global access to second-hand CNC equipment by 2026.

Sustainability and Circular Economy Pressures

Environmental regulations and corporate sustainability goals will drive demand for reusing industrial assets. Reconditioned CNC machines will be marketed not only as cost-saving options but also as eco-friendly alternatives to new manufacturing. In 2026, companies may receive incentives or ESG (Environmental, Social, and Governance) recognition for investing in refurbished machinery, further boosting market growth.

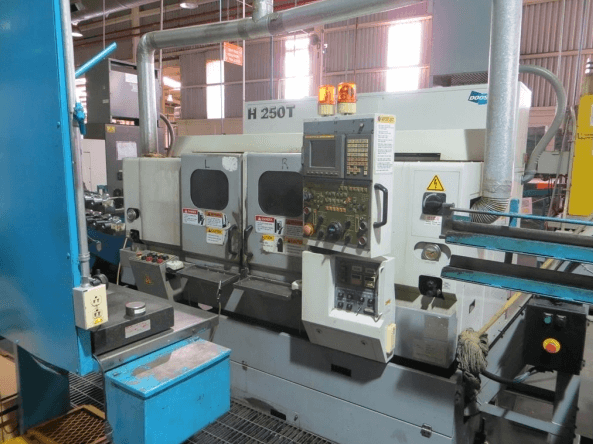

Regional Market Divergence

Developed markets (North America, Western Europe) will see steady demand for high-precision, late-model used machines, often sourced from companies upgrading to automation. In contrast, developing regions (Southeast Asia, Africa, Latin America) will experience rapid growth in demand for basic to mid-range used CNC machines, fueled by expanding manufacturing sectors and limited capital.

Impact of Automation and Labor Shortages

As automation becomes critical in addressing labor shortages, companies will seek affordable CNC solutions to maintain competitiveness. Used CNC machines equipped for lights-out manufacturing or integration with robotic cells will see higher demand. Suppliers offering turnkey used systems with automation-ready features will capture a growing segment by 2026.

In summary, the 2026 second-hand CNC machine market will be characterized by smarter, more connected, and sustainable solutions, supported by digital platforms and driven by economic and environmental imperatives. Sellers and buyers alike must adapt to technological standards and global market dynamics to thrive.

Common Pitfalls When Sourcing a Second-Hand CNC Machine (Quality & IP Issues)

Logistics & Compliance Guide for Second-Hand CNC Machines

Understanding Regulatory Requirements

Before importing or transporting a second-hand CNC machine, it’s essential to understand the regulatory framework in both the exporting and importing countries. Key considerations include customs regulations, import duties, environmental standards, and restrictions on used industrial equipment. Many countries require conformity assessments or certifications to ensure compliance with safety and technical standards (e.g., CE marking in the EU, UL in the U.S.). Verify whether the machine meets current safety and electromagnetic compatibility (EMC) standards. Some jurisdictions may also require a pre-shipment inspection or a certificate of origin.

Documentation and Paperwork

Accurate and complete documentation is crucial for smooth logistics. Required documents typically include:

– Commercial invoice detailing the machine’s description, value, and transaction terms

– Bill of lading or airway bill

– Packing list with dimensions, weight, and contents

– Certificate of origin

– Export/import licenses (if applicable)

– Equipment conformity certificates (e.g., CE, ISO)

– Previous ownership and maintenance records (recommended)

For U.S. imports, an Importer Security Filing (ISF) may be required. For EU imports, a customs declaration via the Import Control System (ICS) is necessary. Always confirm documentation requirements with local customs authorities or a licensed customs broker.

Transportation and Packaging

Second-hand CNC machines are often heavy, bulky, and sensitive to shock and moisture. Use appropriate crating—preferably wooden or metal skids with bracing—to secure all moving parts and protect delicate components like spindles and control panels. Disassemble and label parts if needed for easier transit. Choose a freight forwarder experienced in industrial machinery, and opt for insured freight (marine or cargo insurance). Consider shipping methods: sea freight for cost efficiency on large machines, air freight for urgent or smaller units. Plan for lift gate service or forklift unloading at both ends.

Import Duties and Taxes

Import costs can significantly affect the total price of a used CNC machine. Research the applicable Harmonized System (HS) code—typically under 8456 (machining centers, multi-tasking machines) or 8457 (machining centers for metal)—to determine duty rates. Some countries apply reduced or zero tariffs on used industrial machinery under specific conditions. Additionally, value-added tax (VAT), goods and services tax (GST), or other local taxes may apply upon import. Factor in customs clearance fees and potential storage charges if inspections delay release.

Environmental and Safety Compliance

Ensure the machine complies with environmental regulations, especially regarding coolants, oils, and waste materials. Some regions enforce strict rules on the import of equipment containing hazardous substances (e.g., PCBs in older electrical panels). Confirm that the machine meets current safety standards, including emergency stops, guarding, and proper grounding. If modifications are needed post-import (e.g., voltage conversion or control system updates), work with a qualified technician to ensure compliance with local workplace safety codes (e.g., OSHA in the U.S., Machinery Directive in the EU).

Inspection and Testing Upon Arrival

Conduct a thorough inspection immediately upon delivery. Check for transit damage, missing components, and verify functionality. Compare the machine to the documentation and any pre-shipment inspection reports. If possible, perform a test run to assess mechanical performance, calibration, and software operation. Notify the carrier and insurer promptly of any damage or discrepancies to initiate claims. Retain all records for compliance audits and potential resale.

After-Sales Compliance and Registration

Some jurisdictions require registration of industrial machinery with local authorities or safety agencies. Maintain records of maintenance, repairs, and safety certifications. Ensure software licenses (e.g., for CNC controls) are transferable or obtain new licenses as needed. Updating outdated operating systems or control software may be necessary for security and compatibility. Compliance doesn’t end at import—ongoing adherence to safety and operational standards is critical for legal and safe use.

Conclusion: Sourcing a Second-Hand CNC Machine

Sourcing a second-hand CNC machine can be a cost-effective and practical solution for businesses or individuals seeking to enter or expand in precision manufacturing without the high capital investment of new equipment. With proper due diligence, it is possible to acquire a reliable, high-performance machine that meets operational requirements and offers a strong return on investment.

Key factors in successful sourcing include assessing the machine’s condition, age, maintenance history, and compatibility with existing workflows. Evaluating the seller’s reputation, requesting live demonstrations, and, where possible, involving technical experts in the inspection process significantly reduce the risk of post-purchase issues. Additionally, considering availability of spare parts, technical support, and software compatibility ensures long-term usability and minimizes downtime.

While second-hand CNC machines may come with certain limitations—such as outdated controls or wear and tear—the benefits often outweigh the drawbacks when a strategic and informed approach is taken. Ultimately, sourcing a pre-owned CNC machine, when done carefully, offers an excellent balance between performance, affordability, and scalability, making it a smart choice for many manufacturing environments.