The global extension cord market has experienced steady expansion in recent years, driven by rising demand across residential, commercial, and industrial sectors. According to Grand View Research, the global extension cord market size was valued at USD 3.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. This growth is fueled by increased construction activities, growing reliance on portable power solutions, and the proliferation of outdoor electrical applications. Within this expanding market, 25-foot 12-gauge extension cords have become particularly popular due to their optimal balance of length, durability, and current-carrying capacity—making them ideal for heavy-duty tools and outdoor equipment. As demand for reliable, high-performance cords rises, several manufacturers have emerged as industry leaders, combining innovation, safety compliance, and scalability to capture significant market share. The following analysis identifies the top 8 manufacturers excelling in the production of 25-foot 12-gauge extension cords, based on product quality, distribution reach, and market presence.

Top 8 25Ft 12 Gauge Extension Cord Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

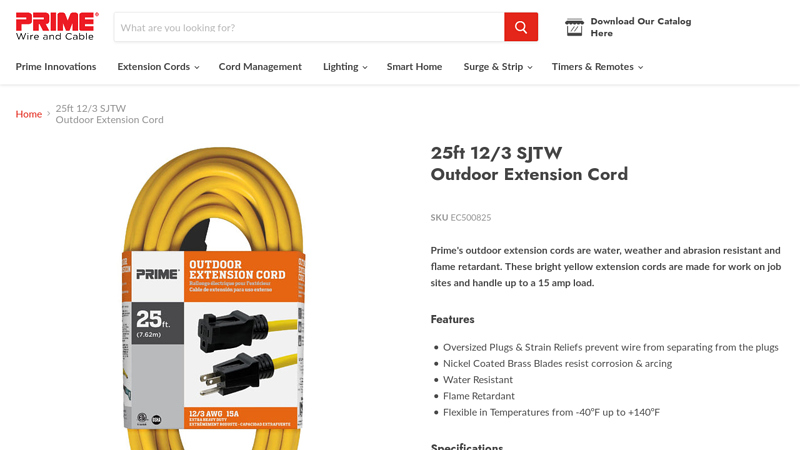

#1 25ft 12/3 SJTW Outdoor Extension Cord

Domain Est. 1998

Website: primewirecable.com

Key Highlights: Rating 1.0 (1) These bright yellow extension cords are made for work on job sites and handle up to a 15 amp load. Features. Oversized Plugs & Strain Reliefs prevent wire from ……

#2 Extension Cords

Domain Est. 1994

Website: southwire.com

Key Highlights: Keep your home or workplace powered up with our selection of durable and reliable extension cords….

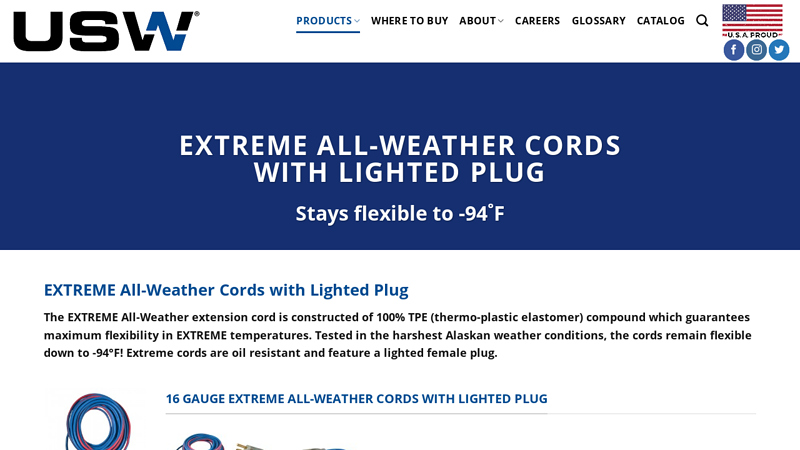

#3 EXTREME All

Domain Est. 1997

Website: uswireandcable.com

Key Highlights: In stock Free deliveryThe EXTREME All-Weather extension cord is constructed of 100% TPE (thermo-plastic elastomer) compound which guarantees maximum flexibility in EXTREME ……

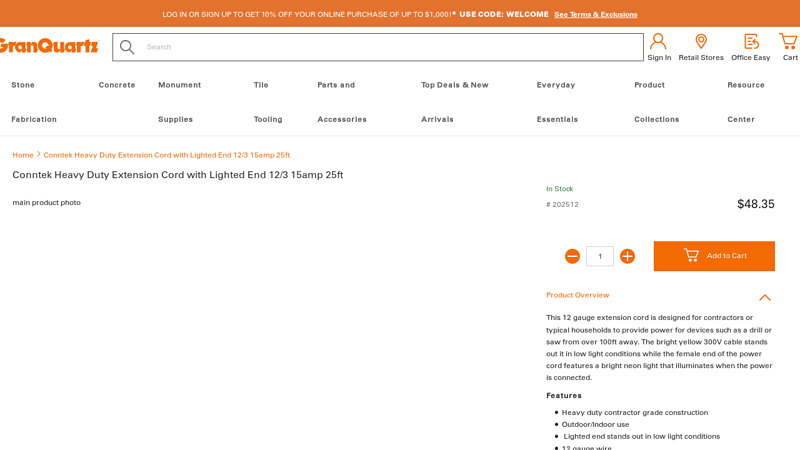

#4 Conntek Heavy Duty Extension Cord with Lighted End 12/3 15amp …

Domain Est. 1997

Website: granquartz.com

Key Highlights: This 12 gauge extension cord is designed for contractors or typical households to provide power for devices such as a drill or saw from over 100ft away. The ……

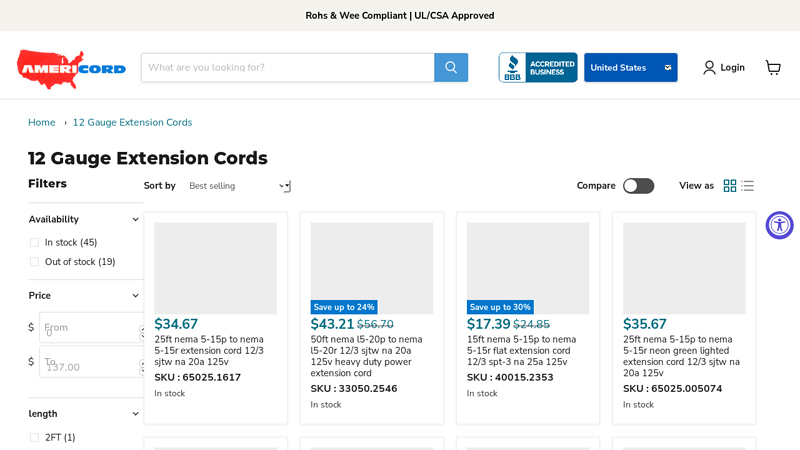

#5 12 Gauge Extension Cords

Domain Est. 1999

Website: americord.com

Key Highlights: Free delivery 30-day returnsAmericord’s 12-gauge extension Nema -5 cords are used with high power appliances. Rated at 20 amps, available in different sizes. Order Now….

#6 25 Ft 12 Gauge Extension Cord

Domain Est. 2012

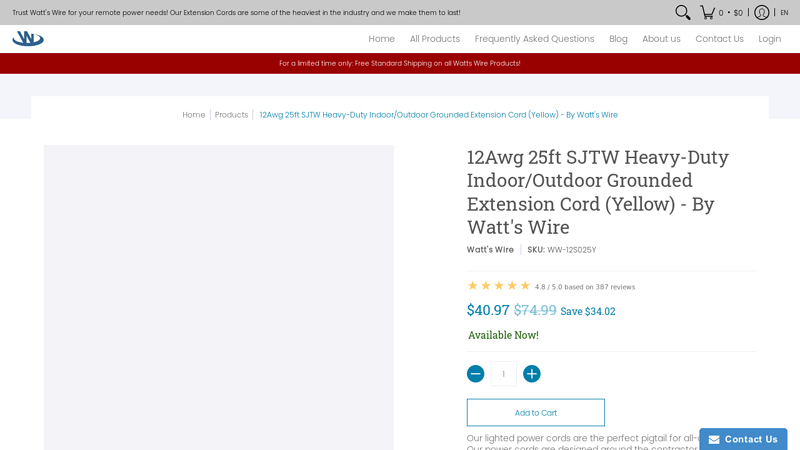

#7 25ft 12Awg SJTW UL Extension Cord (Yellow)

Domain Est. 2016

Website: wattswire.com

Key Highlights: In stock Free deliveryAll of our cords are heavy gauge copper conductors designed to minimize voltage drop and meet a full 15 amp or 1875 watt for any cord length you select….

#8 Shop Extension Cords: Heavy-Duty, Outdoor, & More

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day deliveryShop premium extension cords at Do it Best, including regular extension cords and retractable extension cord reels. Get same day pick-up or home delivery….

Expert Sourcing Insights for 25Ft 12 Gauge Extension Cord

H2: 2026 Market Trends for 25-Foot 12-Gauge Extension Cords

The market for 25-foot 12-gauge extension cords is poised for significant evolution by 2026, shaped by technological advancements, shifting consumer preferences, regulatory developments, and growing demand across both residential and commercial sectors. As a staple in power delivery for high-demand tools and equipment, the 12-gauge variant—known for its robust current-carrying capacity—remains a critical product category within the broader electrical accessories market.

1. Rising Demand in Residential and DIY Markets

The surge in home improvement projects, driven by remote work trends and increased homeownership, is expected to sustain demand for high-performance extension cords. By 2026, the DIY (Do-It-Yourself) segment will remain a key growth driver, with consumers favoring durable, safe, and weather-resistant 25-foot 12-gauge cords for outdoor power tools, landscaping equipment, and holiday lighting. Enhanced product labeling and safety certifications will play a pivotal role in consumer decision-making.

2. Focus on Safety and Compliance

Regulatory standards, particularly from OSHA and UL (Underwriters Laboratories), will tighten around cord durability, heat resistance, and grounding mechanisms. In 2026, manufacturers will increasingly adopt smart compliance features, such as overheating protection and grounded outlets with indicator lights. The 12-gauge cord’s ability to handle up to 20 amps safely over 25 feet aligns well with NEC (National Electrical Code) guidelines, reinforcing its position as a go-to solution for high-load applications.

3. Growth in Commercial and Industrial Applications

Construction, event management, and agricultural sectors will continue to adopt 25-foot 12-gauge cords for their balance of length and power efficiency. With an emphasis on job site safety and equipment reliability, commercial buyers will favor cords with reinforced jackets (e.g., SJTW or SOOW ratings), UV resistance, and abrasion protection. Rental equipment companies are also expected to bulk-purchase these cords, contributing to B2B market expansion.

4. Sustainability and Material Innovation

Environmental concerns will influence material sourcing and end-of-life recyclability. By 2026, leading manufacturers will shift toward PVC-free or low-smoke zero-halogen (LSZH) jacketing materials to reduce environmental impact. Additionally, modular designs and repairable connectors may emerge to extend product lifespan and support circular economy principles.

5. E-Commerce and Brand Differentiation

Online retail platforms will dominate sales channels, with detailed product comparisons, customer reviews, and video demonstrations influencing purchase behavior. Brands that emphasize durability testing data, warranty terms, and bundled accessories (e.g., cord reels or storage bags) will gain competitive advantage. Private-label and subscription-based models may also enter the space, particularly on marketplaces like Amazon and Home Depot’s online store.

6. Integration with Smart Technology (Emerging Trend)

While still in early stages, smart extension cords with energy monitoring, surge protection, and mobile app integration may begin to enter the market by 2026. Though more common in indoor power strips, these features could eventually extend to heavy-duty outdoor cords, especially for professional users seeking real-time load data and fault alerts.

Conclusion

By 2026, the 25-foot 12-gauge extension cord market will be characterized by heightened safety standards, material innovation, and digital retail dominance. Its core value—delivering reliable, low-voltage-drop power over practical distances—will ensure sustained demand across multiple sectors. Manufacturers that prioritize durability, compliance, and customer education will be best positioned to capture market share in this mature yet evolving category.

Common Pitfalls When Sourcing a 25ft 12 Gauge Extension Cord (Quality & IP Rating)

When sourcing a 25-foot 12-gauge extension cord, especially for demanding applications, several critical pitfalls related to quality and Ingress Protection (IP) rating can compromise safety, performance, and longevity. Avoiding these common mistakes ensures you get a reliable and safe product.

Choosing Low-Quality Materials and Construction

Many budget extension cords use substandard materials to cut costs. Look out for thin, brittle PVC jackets that crack in cold weather or degrade under UV exposure. Poorly molded connectors with weak strain reliefs can lead to internal wire damage and electrical hazards. Always inspect the cord’s flexibility, jacket thickness, and connector durability—higher-quality cords feel substantial and are built to withstand regular use.

Ignoring True 12-Gauge Wire (Wire Gauge Fraud)

Not all cords labeled as “12 gauge” actually contain 12 AWG wire. Some manufacturers misrepresent the gauge, using thinner 14 or 16-gauge wire to reduce costs. A genuine 12-gauge cord can safely handle higher amperage (typically up to 20 amps) and minimize voltage drop over 25 feet—critical for power tools and outdoor equipment. Verify the wire gauge by checking independent reviews or physically measuring the conductor (if possible), and purchase from reputable brands with certifications.

Overlooking Ingress Protection (IP) Rating for Outdoor Use

For outdoor or damp environments, the IP rating is essential. Many standard extension cords lack proper IP ratings, making them unsafe in wet conditions. A cord without at least an IP44 rating (protected against splashing water and solid objects larger than 1mm) risks short circuits or electrocution. Always ensure the cord is rated for outdoor use with a valid IP rating—look for features like sealed ends and weather-resistant jackets.

Assuming All Extension Cords Are Suitable for Heavy-Duty Applications

Even with a 12-gauge wire, some cords are not designed for continuous or high-load use. Using a cord not rated for heavy-duty applications (e.g., powering air compressors or construction tools) can lead to overheating and fire hazards. Check for OSHA, UL, or ETL listings indicating compliance with safety standards for industrial or job-site use.

Failing to Verify Safety Certifications

Uncertified cords may not meet electrical safety standards, increasing the risk of fire or shock. Avoid cords without clear UL, ETL, CSA, or other recognized safety certifications. These marks indicate the product has been independently tested for electrical and fire safety—especially important in commercial or industrial procurement.

Neglecting Cord Jacket Durability and Temperature Ratings

The jacket material must withstand environmental stressors. Cords with poor UV resistance deteriorate quickly in sunlight, while those without cold-weather flexibility become brittle and crack in low temperatures. Check the temperature rating (e.g., -20°C to 90°C) and ensure the jacket is oil- and abrasion-resistant for rugged use.

By avoiding these pitfalls—prioritizing verified gauge, IP rating, material quality, and safety certifications—you ensure a durable, safe, and high-performing 25ft 12-gauge extension cord suited to your specific needs.

Logistics & Compliance Guide for 25 ft 12 Gauge Extension Cord

Product Overview

The 25 ft 12 Gauge Extension Cord is a heavy-duty electrical accessory designed to safely power high-wattage tools and appliances. With its 12 AWG copper conductors, it supports up to 15 amps and 125 volts, making it ideal for construction sites, outdoor equipment, and industrial environments. Proper logistics handling and regulatory compliance are essential for safe distribution and consumer use.

Regulatory Compliance Requirements

Electrical Safety Certification

All extension cords sold in the United States must comply with safety standards set by nationally recognized testing laboratories (NRTL). The 25 ft 12 Gauge Extension Cord must be:

– Certified by UL (Underwriters Laboratories) under UL 817 – Standard for Cord Sets and Power-Supply Cords.

– Marked with the UL listing symbol and relevant product information (voltage, amperage, gauge, length, manufacturer).

– Tested for insulation integrity, grounding continuity, and resistance to heat and abrasion.

Labeling and Packaging Requirements

- Each unit must display permanent, legible labeling including:

- Voltage (125V)

- Amperage (15A)

- Wire gauge (12 AWG)

- Cord length (25 ft)

- Manufacturer or private label name

- UL or ETL certification mark

- Retail packaging must include safety warnings, usage instructions, and compliance marks.

- Bilingual labeling (English/Spanish) is required for distribution in certain regions, including California and parts of Texas.

Environmental and Material Regulations

- Compliant with RoHS (Restriction of Hazardous Substances) directives, restricting lead, mercury, cadmium, and other hazardous materials.

- Meets California Proposition 65 requirements—warning labels are required if the product contains listed chemicals such as lead in PVC insulation.

- Packaging materials should follow FTC Green Guides to avoid unsubstantiated environmental claims.

Logistics and Distribution Guidelines

Storage and Handling

- Store in dry, temperature-controlled environments (40°F to 100°F) to prevent PVC jacket degradation.

- Avoid direct sunlight and prolonged exposure to UV radiation.

- Coils must remain intact during storage; avoid kinking or crushing to maintain conductor integrity.

- Keep away from flammable materials and corrosive chemicals.

Shipping and Transportation

- Packed in sturdy corrugated cartons with internal dividers to prevent tangling and damage.

- Standard box dimensions: 10″ x 10″ x 4″ (approx.), weight: 4–5 lbs per unit.

- Use palletized loads for bulk shipments (typically 48 units per pallet, stacked 6 high).

- Label outer packaging with:

- Product SKU and UPC

- “Fragile – Handle with Care”

- “Do Not Stack Over 6 High”

- Compliance marks (UL, RoHS, Prop 65)

Import and Customs Compliance (International Shipments)

- For imports into the U.S.:

- File entry documentation with U.S. Customs and Border Protection (CBP).

- Provide proof of UL certification and conformity with 16 CFR Part 1110.

- Declare correct HTS code: 8544.49.90 (Insulated wire, not elsewhere specified).

- For exports: Verify destination country’s electrical standards (e.g., CE for EU, CSA for Canada).

- Maintain a Certificate of Conformity (CoC) and test reports from accredited labs.

Warranty and Consumer Safety

Warranty Policy

- Standard 2-year limited warranty against defects in materials and workmanship.

- Excludes damage from misuse, overloading, or outdoor use without wet-location rating.

- Warranty claims require proof of purchase and product registration.

Safety and Recall Procedures

- Monitor field reports through customer service and retail partners.

- In case of safety issues (e.g., overheating, insulation failure), initiate a recall per CPSC (Consumer Product Safety Commission) guidelines.

- Register products with the CPSC’s Recall Agent Network if necessary.

- Maintain traceability via batch/lot numbers printed on packaging and labels.

Conclusion

The 25 ft 12 Gauge Extension Cord must meet stringent electrical safety, labeling, and environmental standards to ensure compliance and consumer safety. Efficient logistics planning—including proper storage, packaging, and customs documentation—supports smooth distribution. Ongoing monitoring and adherence to recall protocols are essential for brand protection and regulatory compliance.

After evaluating various options, the best approach for sourcing a 25-foot, 12-gauge extension cord is to prioritize safety, durability, and reliability. A 12-gauge cord is suitable for heavy-duty applications and longer runs with minimal voltage drop, making it ideal for power tools, outdoor equipment, or demanding indoor use. When sourcing, consider cords constructed with outdoor-rated, weather-resistant jackets (such as SJTW or SJEOW) for added safety and longevity, especially if used in varied or harsh environments.

Key factors to consider include UL or ETL certification, inclusion of a three-prong grounding plug, and reinforced ends to prevent wear. Reputable brands like Southwire, DEWALT, and Husky offer reliable options available through major retailers such as Home Depot, Lowe’s, or Amazon. Purchasing from a trusted supplier ensures product authenticity, warranty coverage, and access to customer support.

In conclusion, sourcing a 25-foot, 12-gauge extension cord from a reputable manufacturer and supplier ensures safe, efficient power delivery for both residential and commercial applications. Prioritizing build quality and safety certifications will provide long-term value and performance.