The global interior doors market is experiencing steady expansion, driven by rising residential construction, renovation activities, and growing consumer preference for energy-efficient and aesthetically appealing home solutions. According to Grand View Research, the global interior doors market size was valued at USD 21.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. With increasing demand for standardized, easy-to-install solutions, prehung interior doors—particularly in common dimensions like 24 inches—are gaining traction among contractors and DIY homeowners alike. This growth is further amplified by advancements in engineered wood and composite materials, enabling manufacturers to deliver durable, cost-effective, and design-flexible products. As the market becomes more competitive, a select group of manufacturers have emerged as leaders in producing high-quality 24-inch prehung interior doors, combining precision manufacturing, supply chain efficiency, and innovation to meet evolving builder and consumer expectations.

Top 8 24 Inch Prehung Interior Door Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Masonite Residential

Domain Est. 1995

Website: masonite.com

Key Highlights: Explore the best selection of interior and exterior doors for your home. Masonite doors are crafted from the highest quality materials for every home style.Missing: 24 inch…

#2 View all Doors

Domain Est. 1995

Website: thermatru.com

Key Highlights: 1–8 day deliverySearch through all Therma-Tru doors and narrow down by using filtering options to find the perfect entry door for your home … 2’0″ (24 inches); 2’10” (34 inches)…

#3 Interior Doors

Domain Est. 1996

Website: jeld-wen.com

Key Highlights: JELD-WEN interior doors deliver stylish, sophisticated performance that is sure to impress. Choose from glass panel, bifold, louver & all panel design ……

#4 Interior Doors

Domain Est. 1996

Website: stevesdoors.com

Key Highlights: Steves & Sons offers everything from high density fiberwood to flush door for interiors. Molded panel doors are one of our most popular styles….

#5 Interior Doors

Domain Est. 2003

Website: metrie.com

Key Highlights: We offer moulded panel doors in multiple heights and widths, slab and bifold, hollow or solid core, and smooth or textured options. Exclusions apply and vary by ……

#6 Prehung Doors

Domain Est. 2005

#7 MMI DOOR

Domain Est. 2013

Website: mmidoor.com

Key Highlights: We are the largest distributor of wood, steel and fiberglass exterior, interior, storm and patio doors and door products in the US today!…

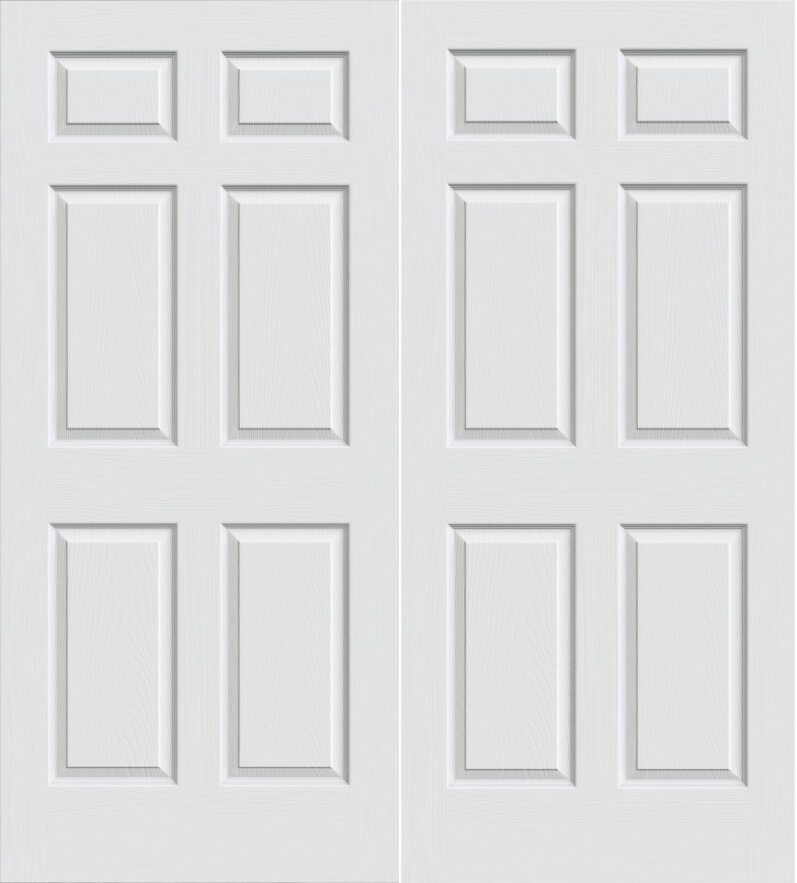

#8 24 in. x 80 in. Right

Domain Est. 2021

Website: burgascoliving.com

Key Highlights: This 24 in. x 80 in. 6-Panel Textured Primed White Hollow Core Interior Prehung Door features a primed 6-Panel design that can be painted or ……

Expert Sourcing Insights for 24 Inch Prehung Interior Door

H2: 2026 Market Trends for 24-Inch Prehung Interior Doors

The market for 24-inch prehung interior doors is poised for notable shifts in 2026, driven by evolving construction practices, consumer preferences, and advancements in manufacturing technologies. Here are the key trends expected to shape this niche segment:

-

Increased Demand in Multi-Family and Accessible Housing

The growing emphasis on accessible and universal design—especially in aging-in-place renovations and multi-family housing developments—is driving demand for narrower door options like the 24-inch prehung door. These doors are commonly used for closets, utility rooms, and ADA-compliant installations, making them essential in adaptive housing projects. With rising investments in affordable and senior-friendly housing, this trend is expected to accelerate through 2026. -

Growth in DIY and Renovation Sectors

As home improvement remains strong post-pandemic, especially among millennials and Gen Z homeowners, the DIY market continues to expand. Prehung doors, including the 24-inch size, are favored for their ease of installation. Retailers and manufacturers are responding with enhanced product labeling, installation guides, and modular packaging, further fueling consumer confidence and adoption. -

Sustainability and Material Innovation

Eco-conscious consumers and stricter building regulations are pushing manufacturers toward sustainable materials such as FSC-certified wood, engineered composites, and recycled content. In 2026, expect to see more 24-inch prehung doors made from low-VOC materials and with improved thermal and acoustic insulation properties, aligning with green building standards like LEED and ENERGY STAR. -

Supply Chain Optimization and Regional Manufacturing

Lessons learned from recent global supply chain disruptions have led to a reshoring trend in building materials production. U.S. and European manufacturers are increasingly producing prehung doors domestically to reduce lead times and transportation costs. This shift supports faster delivery of standard sizes like the 24-inch door, improving inventory reliability for contractors and retailers. -

Digital Integration and Customization

E-commerce platforms and B2B procurement tools are enabling greater customization and precision ordering. By 2026, digital configurators will allow builders and homeowners to select door style, finish, hinge placement, and jamb size—including 24-inch prehung units—with real-time pricing and lead time estimates. This trend enhances efficiency and reduces returns due to sizing errors. -

Competitive Pricing Amid Margin Pressures

While raw material costs may stabilize by 2026, labor and logistics expenses remain a challenge. Manufacturers are leveraging automation in pre-hanging processes to maintain affordability. The 24-inch size, being a standard dimension, benefits from economies of scale, keeping it competitively priced compared to custom alternatives.

In summary, the 2026 market for 24-inch prehung interior doors will be shaped by accessibility needs, sustainability demands, and digital innovation. As a staple in both residential renovations and new construction, this product category is expected to see steady growth, supported by efficient supply chains and rising DIY engagement.

Common Pitfalls Sourcing a 24-Inch Prehung Interior Door (Quality & Installation Performance)

Sourcing a 24-inch prehung interior door, often used for closets or utility spaces, can be fraught with challenges. Understanding these common pitfalls related to quality and installation performance (IP) is crucial for a successful project.

Quality Concerns with Thin or Low-Grade Materials

24-inch doors are frequently thinner (often 1-3/8″) and made from lower-grade materials compared to standard 30-inch or 32-inch doors. This can lead to flimsy construction, poor sound insulation, warping over time, and susceptibility to damage. Always verify the door’s core material (solid core vs. hollow core) and overall thickness to ensure it meets your durability and acoustic requirements.

Inconsistent Pre-Cut Hinge and Strike Plate Locations

Prehung doors come with hinges mortised and a strike plate hole pre-drilled. However, 24-inch doors may have non-standard hinge spacing or strike plate placement that doesn’t align with common hardware. This forces on-site modifications, compromising the door’s integrity and increasing labor time. Confirm hinge count, size, and exact locations with the manufacturer before purchase.

Poor Frame Construction and Alignment Issues

The door frame (jamb) in prehung units for smaller doors is sometimes constructed from lower-grade wood or engineered lumber prone to twisting or bowing. This results in uneven gaps, binding during operation, and difficulty achieving a tight seal. Inspect the jamb material and ensure it’s straight and robust enough to support the door long-term.

Limited Availability Leading to Compromised Options

Due to lower demand, 24-inch prehung doors have fewer style, material, and finish options. This scarcity may force buyers to accept subpar aesthetics or performance characteristics. Research suppliers early and verify availability to avoid last-minute compromises on quality or design.

Inaccurate Pre-Sizing Resulting in Installation Delays

Prehung units are built to specific rough opening dimensions. If the actual opening in the wall doesn’t match the ordered size (common in renovations), the door won’t fit properly. This leads to costly delays, potential reordering, or unprofessional modifications. Always double-check and verify rough opening measurements before ordering.

Subpar Weatherstripping and Insulation in Interior Applications

While often overlooked for interior doors, poor or absent weatherstripping in the jamb can allow sound and airflow to pass through, especially in closets or utility rooms. This reduces energy efficiency and acoustic privacy. Check if the unit includes compression seals or gaskets, particularly important for rooms requiring sound control.

Inadequate Packaging Leading to Shipping Damage

Smaller prehung units may receive less robust packaging, increasing the risk of damage during transit—such as bent jambs, chipped edges, or misaligned hinges. Inspect the door thoroughly upon delivery and report any defects immediately to avoid installation issues and delays.

Logistics & Compliance Guide for 24 Inch Prehung Interior Door

Product Overview

A 24-inch prehung interior door is a ready-to-install door unit consisting of a door slab, frame, hinges, and often a pre-cut opening for a lockset. It is commonly used in closets, utility rooms, or tight spaces where a standard 30-inch or 32-inch door is too wide. Proper handling, transportation, and compliance with building codes and safety standards are essential throughout the supply chain.

Packaging & Handling Requirements

Prehung doors must be packaged to prevent warping, damage to the finish, and misalignment of the frame. Use protective corner guards, shrink-wrapping, and sturdy cardboard or wooden skids. Doors should always be stored and transported vertically to avoid stress on the frame. Never lift or carry by the door knob or hinges. Handle with clean gloves to avoid smudging or scratching the surface.

Transportation & Storage Conditions

Transport doors in a climate-controlled, dry environment to prevent moisture absorption, swelling, or warping. Avoid exposure to direct sunlight, rain, or extreme temperatures. Store indoors on a level surface, elevated off the ground, and maintain at least 6 inches of clearance around each unit for air circulation. Allow acclimation to the installation environment for a minimum of 48 hours prior to installation.

Freight Classification & Shipping

According to the National Motor Freight Classification (NMFC), prehung interior doors typically fall under Class 150–175 due to low density and susceptibility to damage. Use LTL (Less-Than-Truckload) carriers experienced in handling fragile, oversized freight. Secure doors with straps to prevent shifting during transit. Confirm carrier insurance coverage for freight claims in case of damage.

International Shipping & Import Compliance

For cross-border shipments, ensure compliance with destination country regulations. Provide accurate Harmonized System (HS) codes—typically 4418.20 for wooden doors or 3926.30 for composite materials. Include certificates of origin, detailed invoices, and phytosanitary certificates if required. Verify compliance with the U.S. Lacey Act (for wood products) and EU Timber Regulation (EUTR) to confirm legal sourcing of raw materials.

Building Code & Safety Compliance

Ensure all prehung doors meet applicable building codes, such as the International Residential Code (IRC) and International Building Code (IBC). Verify that doors comply with egress requirements where applicable—note that a 24-inch door may not meet minimum egress width standards (typically 32 inches) for habitable rooms. Confirm fire ratings if used in fire-rated assemblies (though most 24-inch prehung doors are non-rated). Label doors per ASTM E2074 or UL standards when fire-rated.

Environmental & Sustainability Standards

Manufacturers and suppliers must adhere to environmental regulations such as CARB (California Air Resources Board) Phase 2 for formaldehyde emissions in composite wood products. Consider sourcing doors certified by FSC (Forest Stewardship Council) or SCS Global Services to meet green building requirements like LEED. Provide Environmental Product Declarations (EPDs) when requested.

Installation & Final Compliance Verification

Prior to installation, inspect the door for damage and ensure it matches the approved specifications. Confirm frame alignment, hinge function, and latch operation. Verify that the installed door meets local accessibility standards under the ADA or similar regulations—note that 24-inch doors generally do not meet accessibility width requirements (minimum 32 inches clear opening). Document compliance through inspection reports or certifications as needed for permits.

Return & Damage Claims Procedure

Establish a clear process for handling damaged or incorrect shipments. Require photos and detailed descriptions within 48 hours of delivery. Retain all packaging for carrier inspection. Submit claims promptly with freight bill, proof of damage, and repair/replacement estimates. Track and analyze return reasons to improve logistics quality.

In conclusion, sourcing a 24-inch prehung interior door requires careful consideration of material, quality, price, and availability. While 24-inch doors are less common than standard sizes, they can typically be found through specialty suppliers, online retailers, or local building supply stores that cater to custom or retrofit needs. Prehung doors offer the advantage of easier installation due to the frame being already attached, ensuring proper alignment and reducing labor time. When sourcing, it’s important to verify measurements, door-handing, jamb size, and local building codes to ensure compatibility with the opening. Comparing options from multiple vendors—both online and in-store—can help secure the best value without compromising on durability or aesthetics. Ultimately, with proper research and planning, a 24-inch prehung interior door can be successfully sourced to meet functional and design requirements for bathrooms, closets, or other compact spaces.