The global market for electrical connectors, including 220V AC plug types, is experiencing steady growth driven by rising electrification, infrastructure development, and increased demand in residential, commercial, and industrial sectors. According to Grand View Research, the global electrical connectors market was valued at USD 86.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. A significant portion of this growth can be attributed to the widespread adoption of 220V electrical systems across Europe, Asia, Africa, and parts of South America, where standardization and safety compliance are key drivers for plug and socket manufacturing. Additionally, Mordor Intelligence projects continued demand surge in emerging economies due to urbanization and expanding power grids, further fueling the need for reliable and region-specific 220V AC plug solutions. As regulatory standards tighten and product differentiation grows, manufacturers are focusing on innovation, durability, and compliance with international certifications such as IEC, CE, and VDE. In this competitive landscape, a select group of manufacturers has emerged as leaders in producing high-quality, region-compliant 220V AC plug types—setting the benchmark for safety, efficiency, and global scalability.

Top 9 220V Ac Plug Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Meltric

Domain Est. 1997

Website: meltric.com

Key Highlights: MELTRIC offers a full line of industrial plugs and receptacles, including our signature brand of UL-listed Switch-Rated devices with DECONTACTOR™ ……

#2 Plugs, Connectors & Receptacles

Domain Est. 1995

Website: leviton.com

Key Highlights: Leviton has the broadest offering of heavy duty, watertight, NEMA and IEC plugs and connectors for commercial and industrial grade applications….

#3 Types of Electrical Connectors and Wire Connectors

Domain Est. 1992

Website: te.com

Key Highlights: We design and manufacture an expansive portfolio of electrical connector types that are engineered to reliably transmit data, power, and signal in the harshest ……

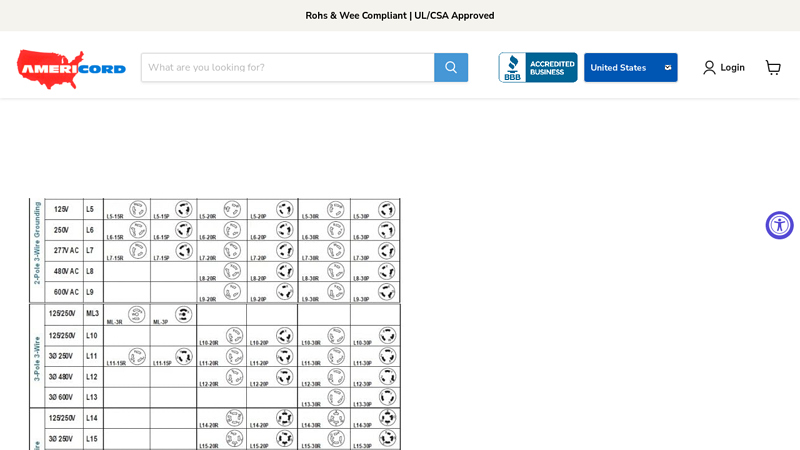

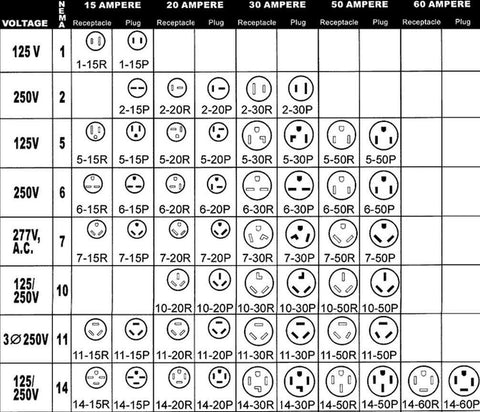

#4 NEMA Plug Charts

Domain Est. 1999

Website: americord.com

Key Highlights: These charts describe the layout of the connector plugs and sockets, voltage, and current limits, for their aim is to offer a uniform means of connecting ……

#5 Products

Domain Est. 1999

Website: phino.com

Key Highlights: Phino Electric is certified for sales of AC power cords, plugs, sockets, connectors around the world….

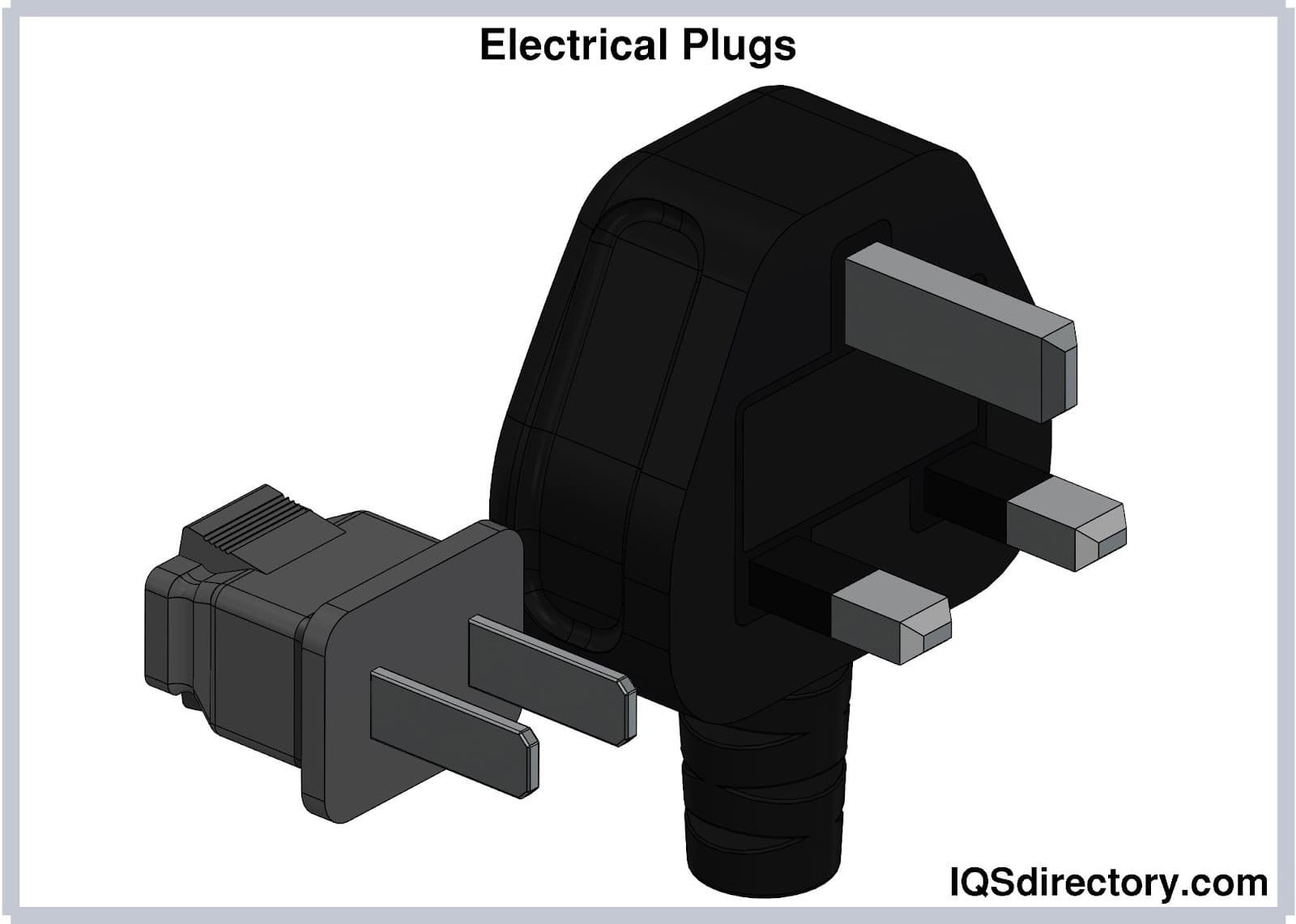

#6 AC power plugs and sockets

Domain Est. 2005

Website: cablefree.net

Key Highlights: AC power plugs and sockets. Electrical plugs and sockets differ from one another in voltage and current rating, shape, size, & connector type globally….

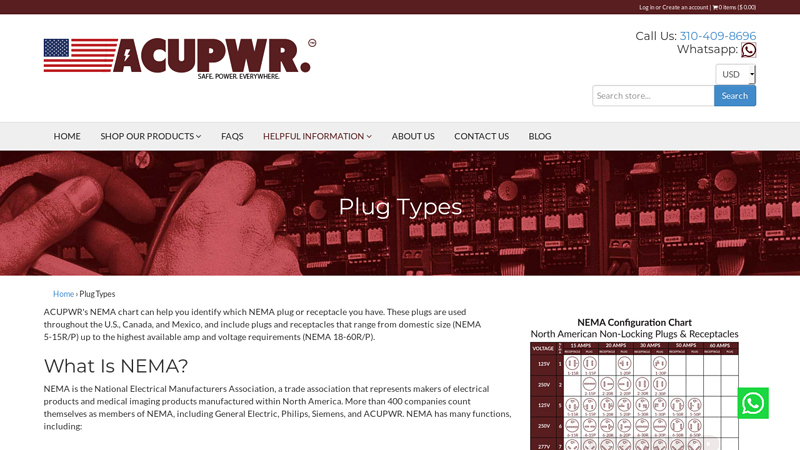

#7 NEMA Chart

Domain Est. 2010

Website: acupwr.com

Key Highlights: ACUPWR’s NEMA chart can help you identify which NEMA plug or receptacle you have. These plugs are used throughout the US, Canada, and Mexico….

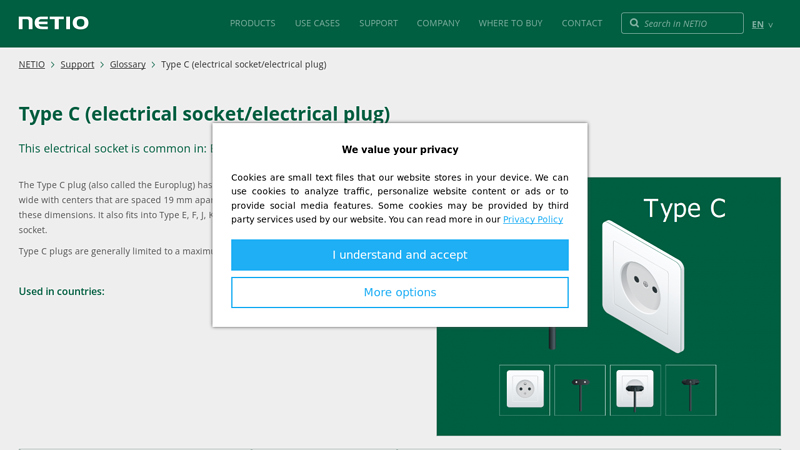

#8 Electrical socket type C European

Domain Est. 2012

Website: netio-products.com

Key Highlights: The Type C plug (also called the Europlug) has two round pins. The pins are 4 to 4.8 mm wide with centers that are spaced 19 mm apart….

#9 World plugs

Website: iec.ch

Key Highlights: Select a location, electric potential or frequency to discover what plug type(s), voltage and frequency are used there….

Expert Sourcing Insights for 220V Ac Plug Types

H2: 2026 Market Trends for 220V AC Plug Types

As global electrification expands and energy standards evolve, the market for 220V AC plug types is poised for significant transformation by 2026. Driven by regional regulations, technological advancements, sustainability goals, and the rise of smart infrastructure, several key trends are shaping the demand, design, and adoption of 220V plug systems worldwide.

-

Regional Standardization and Harmonization Efforts

By 2026, increased efforts toward harmonizing plug types across regions—especially in Europe, parts of Asia, and emerging markets—are expected to gain momentum. The Type F (Schuko) and Type C (Europlug) remain dominant in Europe due to EU standardization, while Type I is prevalent in Australia, New Zealand, and parts of China. However, cross-border e-commerce and multinational appliance manufacturing are pressuring regulators to consider more interoperable solutions. Some countries may adopt dual-compatible sockets or transition toward universal standards to reduce consumer inconvenience and e-waste. -

Growth in Electric Vehicle (EV) Charging Infrastructure

With the global EV market expanding rapidly, 220V AC plugs—particularly Type 2 (Mennekes) in Europe—are becoming central to residential and semi-public charging stations. By 2026, demand for Type 2 connectors is projected to surge as governments push for EV adoption and expand charging networks. These plugs offer higher safety, grounding, and smart communication features, aligning with modern EV requirements. -

Smart Plug Integration and IoT Connectivity

A major trend by 2026 is the integration of smart technologies into traditional 220V plug systems. Smart outlets with energy monitoring, remote control via mobile apps, and compatibility with home automation systems (e.g., Zigbee, Wi-Fi, Matter protocol) are gaining traction. This shift is particularly evident in urban markets in North Asia (e.g., South Korea, Japan) and Western Europe, where energy efficiency and smart home ecosystems are prioritized. -

Focus on Safety and Child-Proof Designs

Regulatory bodies and consumers are increasingly emphasizing electrical safety. By 2026, 220V plugs and sockets are expected to feature enhanced safety mechanisms such as shuttered sockets, overload protection, and tamper-resistant designs—especially in household and educational environments. Countries like India and Brazil are updating electrical codes to mandate these features, driving product redesigns. -

Sustainability and Circular Economy Considerations

Environmental concerns are influencing plug manufacturing. The use of recyclable materials, modular designs for easier repair, and reduced packaging are becoming standard. Additionally, initiatives to phase out non-compliant or hazardous plugs (e.g., ungrounded variants) are gaining support under circular economy models, particularly in the EU’s Ecodesign Directive framework. -

Rising Demand in Emerging Economies

In regions such as Southeast Asia, the Middle East, and Africa, increasing access to 220V electricity grids is fueling demand for reliable plug systems. While legacy plug types (e.g., Type D, M) persist, there is a gradual shift toward more modern, safer designs like Type G (UK-style) or hybrid sockets supporting multiple plug formats. This transition is supported by foreign investment and infrastructure development programs. -

Impact of Plug-and-Play Renewable Energy Systems

With the proliferation of solar microgrids and home energy storage, 220V plug compatibility with decentralized systems is becoming critical. By 2026, manufacturers are likely to design plugs and sockets that integrate seamlessly with inverters and battery systems, supporting plug-and-play renewable energy adoption in off-grid and urban settings alike.

Conclusion

The 2026 landscape for 220V AC plug types reflects a convergence of safety, sustainability, digitalization, and global standardization. While regional differences will persist, the momentum toward smarter, safer, and more interoperable plug systems is unmistakable. Stakeholders—from manufacturers to policymakers—must adapt to these trends to meet evolving consumer needs and regulatory expectations in a rapidly electrifying world.

Common Pitfalls When Sourcing 220V AC Plug Types (Quality & IP Rating)

Sourcing 220V AC plug types—especially for international markets or industrial applications—requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking critical factors can lead to safety hazards, product failures, non-compliance, and costly recalls. Below are common pitfalls to avoid:

Poor Quality Materials and Construction

One of the most frequent issues is selecting plugs made from substandard materials. Low-cost suppliers may use brittle plastics, undersized conductors, or inadequate strain reliefs. These compromises increase the risk of overheating, cracking, electrical arcing, or mechanical failure under repeated use. Always verify material specifications (e.g., UL94 V-0 rated thermoplastics) and request independent test reports or certifications.

Misunderstanding or Ignoring IP Ratings

Ingress Protection (IP) ratings define a plug’s resistance to dust and moisture. A common mistake is assuming that all 220V plugs are suitable for harsh environments. For example, using an IP20-rated plug (basic indoor protection) outdoors or in wet industrial settings can lead to short circuits and safety hazards. Ensure the IP rating matches the intended environment—such as IP44 for outdoor use or IP67 for temporary submersion.

Inconsistent or Fake Certifications

Many suppliers claim compliance with international standards (e.g., IEC, CE, UL) without valid certification. Counterfeit or self-declared certifications are widespread, especially in online marketplaces. Always request certified test reports from accredited laboratories and verify certification numbers with the issuing body. Lack of proper certification can void insurance and result in regulatory penalties.

Mismatched Plug Standards for Target Markets

Using the wrong plug type (e.g., Type C, F, G, or I) for a specific region can render equipment unusable or non-compliant. For example, supplying Type F (Schuko) plugs in the UK, which primarily uses Type G, creates compatibility and safety issues. Confirm regional requirements and ensure plugs meet local regulatory standards, including pin dimensions and earthing mechanisms.

Inadequate Attention to Temperature and Current Ratings

Plugs rated below the required current or operating temperature can overheat, especially under continuous load. A plug rated for 10A may fail when used on a 16A circuit. Always ensure the plug’s current and temperature ratings exceed the application’s maximum expected load, with a safety margin. Consider ambient conditions—high-temperature environments demand higher-rated components.

Overlooking Strain Relief and Cable Gland Quality

Weak or poorly designed strain relief mechanisms can lead to internal wire detachment, especially in industrial or mobile applications. Similarly, low-quality cable glands compromise IP ratings by allowing moisture or dust ingress. Inspect the strain relief design and ensure it’s compatible with the cable diameter and application stress.

Supply Chain and Traceability Risks

Relying on single, unverified suppliers—especially from regions with lax manufacturing oversight—increases the risk of inconsistent quality. Lack of traceability makes it difficult to address defects or recalls. Establish relationships with reputable suppliers, conduct factory audits, and require batch traceability to mitigate supply chain vulnerabilities.

By recognizing and addressing these common pitfalls, businesses can ensure the safety, reliability, and compliance of 220V AC plug components in their products.

Logistics & Compliance Guide for 220V AC Plug Types

When shipping electrical products or managing international operations involving 220V power systems, understanding plug types and regulatory compliance is crucial. This guide outlines key considerations for logistics, safety, and adherence to regional standards.

Regional Plug Type Overview (220V Markets)

Different countries use various plug and socket configurations despite sharing a 220–240V AC standard. Key types include:

- Type C (Europlug): 2-pin, ungrounded. Common in Europe, parts of South America, and Africa. Voltage: 220–230V.

- Type E (French): 2-pin + female grounding hole. Used in France, Belgium, Poland.

- Type F (Schuko): 2-pin + side grounding clips. Widely used in Germany, Austria, Netherlands, and Eastern Europe.

- Type G (UK): 3 rectangular pins, fused plug. Used in the UK, Ireland, Malta, and some former British territories. Operates at 230V.

- Type I (Australian): 2 flat pins in V-shape + grounding pin. Used in Australia, New Zealand, China, and Argentina. Voltage: 220–240V.

- Type D (Indian): 3 round pins in triangular pattern. Used in India, Nepal, and Namibia. Voltage: 230V.

- Type M (South African): Similar to Type D but with larger pins. Used in South Africa, Namibia, and Sri Lanka.

Voltage and Frequency Considerations

While many regions use 220–240V, frequency varies:

– 50 Hz: Most of Europe, Asia, Africa, and Australia.

– 60 Hz: Parts of South America (e.g., Brazil), Saudi Arabia.

Ensure equipment is rated for both voltage and frequency. Dual-rated devices (100–240V, 50/60 Hz) simplify global deployment.

Regulatory and Safety Compliance

Electrical products must meet local conformity standards. Key certifications include:

- CE Marking (Europe): Mandatory for products sold in the EEA. Includes compliance with Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

- UKCA (United Kingdom): Required for goods placed on the UK market post-Brexit.

- CCC (China Compulsory Certification): Required for electrical products in China.

- PSE (Japan): Required even if voltage is 100V; relevant for dual-voltage devices.

- RCM (Australia/New Zealand): Indicates compliance with electrical safety and EMC standards.

- BIS (India): Mandatory for selected electronics under the ISI mark scheme.

Always verify whether plug adapters or built-in multi-plug designs are permitted under local regulations.

Logistics and Packaging Requirements

- Plug Variants by Market: Ship products with region-specific plugs. Avoid universal sockets unless certified.

- Labeling: Include voltage, frequency, and compliance marks visibly on packaging and devices.

- Adapters vs. Fixed Plugs: Shipping with fixed regional plugs reduces liability. If using universal power supplies, ensure detachable IEC C5/C7/C13 cables with correct regional mains plugs.

- Documentation: Include user manuals with safety instructions in local languages. Provide compliance statements (DoC) for customs clearance.

Risk Mitigation Strategies

- Product Testing: Conduct pre-compliance testing in target markets.

- Local Representation: Appoint an Authorized Representative in regions like the EU or UK to manage compliance.

- Customs Classification: Use correct HS codes (e.g., 8504.40 for power supplies) to avoid delays.

- Recall Preparedness: Have a plan for recalls due to non-compliance or safety issues.

Summary

Successfully managing logistics for 220V AC plug types requires attention to regional electrical standards, safety certifications, and packaging strategies. Proactive compliance reduces shipment delays, avoids penalties, and ensures user safety. Always consult local regulatory bodies or compliance experts before market entry.

Conclusion for Sourcing 220V AC Plug Types:

When sourcing 220V AC plug types, it is essential to consider regional standards, safety certifications, device compatibility, and regulatory requirements. Unlike voltage, which is often standardized within a range around 220–240V in many countries, plug types vary significantly across regions (e.g., Type C, E, F in Europe; Type I in Australia; Type G in the UK). Therefore, selecting the correct plug type is crucial for both functionality and safety.

Key considerations include:

– Regional Compliance: Always match the plug type to the destination country’s standard to ensure compatibility with local outlets and adherence to electrical codes.

– Certifications: Use plugs and connectors that meet recognized safety standards (e.g., CE, UKCA, SAA, CCC) to ensure reliability and regulatory approval.

– Dual-Voltage Devices: Confirm whether the connected device supports 220V input; most modern electronics are designed for 100–240V and only require a physical plug adapter or replacement cable.

– Power Requirements: For high-power appliances (e.g., heaters, kitchen equipment), ensure the plug and socket can handle the current load and include features like grounding and insulation.

In summary, successfully sourcing 220V AC plugs requires a clear understanding of geographical electrical standards, product safety, and application-specific needs. Ensuring compatibility not only prevents operational issues but also enhances user safety and reduces liability risks. When in doubt, consulting local regulations or working with certified suppliers is recommended.