The global automotive belt market is projected to grow at a CAGR of 4.8% from 2023 to 2030, driven by rising vehicle production and increasing demand for preventive maintenance components, according to Grand View Research. As one of the most popular midsize sedans in automotive history, the 2006 Honda Accord continues to see strong aftermarket demand for critical replacement parts—including drive belts. With an estimated 2.3 million units of the eighth-generation Accord produced worldwide between 2005 and 2007, the need for high-quality, OEM-spec drive belt solutions remains steady among repair and fleet maintenance channels. This sustained vehicle longevity underscores the importance of reliable manufacturing sources. Based on performance data, OEM partnerships, and aftermarket market presence, the following six manufacturers have emerged as the top suppliers of drive belts for the 2006 Honda Accord.

Top 6 2006 Honda Accord Drive Belt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

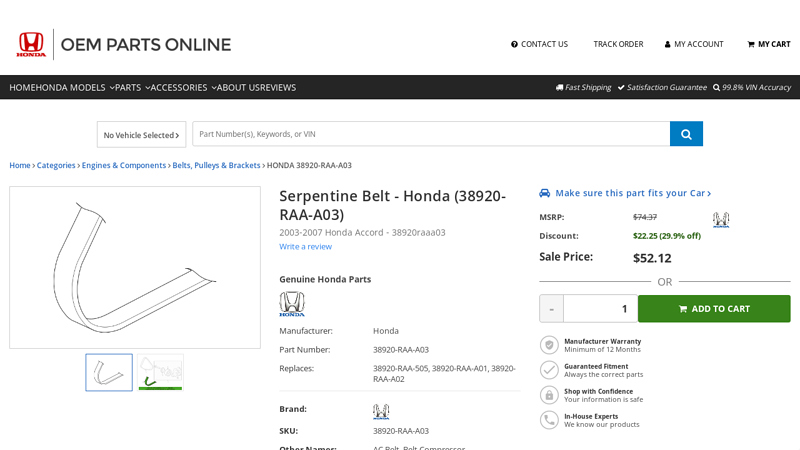

#1 2003

Domain Est. 2015

Website: honda.oempartsonline.com

Key Highlights: All of our parts are genuine OEM parts so we guarantee your Serpentine Belt will perfectly fit your 2003-2007 Honda Accord vehicle….

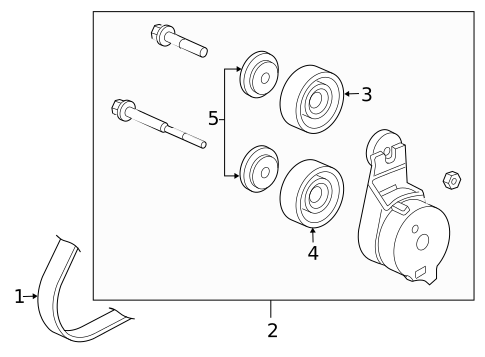

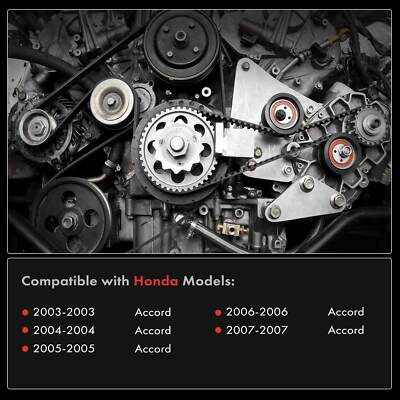

#2 Accessory Drive Belt System Components for 2006 Honda Accord

Domain Est. 1998

#3 DENSO Auto Parts

Domain Est. 2006

Website: densoautoparts.com

Key Highlights: DENSO is a global choice for top automakers, with multiple vehicle models rolling off the assembly line with DENSO auto parts under the hood….

#4 Genuine 2006 Honda Accord Drive Belt & V Belt

Domain Est. 2007

Website: hondapartsnow.com

Key Highlights: 1–4 day delivery · 15-day returnsSpecially designed for the 2006 Honda Accord, this Drive Belt & V Belt offers superior reliability and ease of installation for anyone….

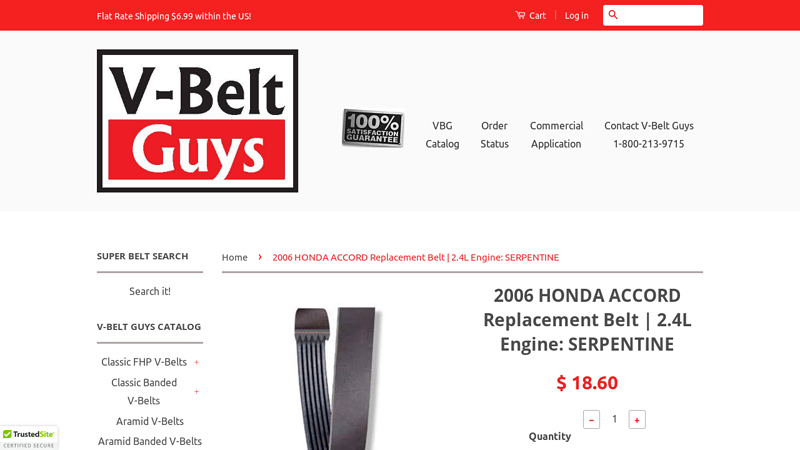

#5 2006 HONDA ACCORD Replacement Belt

Domain Est. 2015

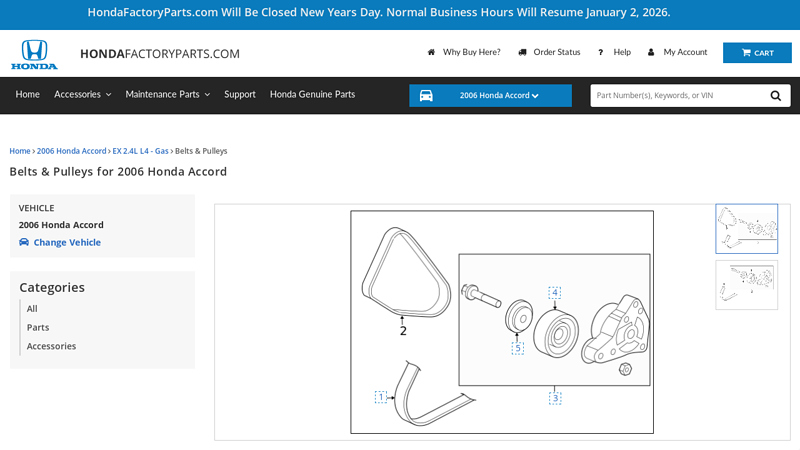

#6 Belts & Pulleys for 2006 Honda Accord

Domain Est. 2017

Expert Sourcing Insights for 2006 Honda Accord Drive Belt

H2: 2026 Market Trends for 2006 Honda Accord Drive Belt

As of 2026, the market for the 2006 Honda Accord drive belt continues to reflect broader shifts in the automotive aftermarket industry, influenced by vehicle age, parts availability, consumer behavior, and technological advancements. Although the 2006 model is now two decades old, a significant number of these vehicles remain on the road, sustaining demand for replacement parts like the drive belt (also known as the serpentine belt). Key market trends in 2026 include:

-

Declining but Steady Demand

The 2006 Honda Accord has entered the “mature vehicle” phase, with many units approaching or exceeding 200,000 miles. While overall vehicle population is gradually decreasing due to retirements, a loyal base of owners continues to maintain their Accords due to the model’s reputation for reliability. This supports steady, albeit slowly declining, demand for drive belts. Replacement intervals (typically every 60,000–100,000 miles) ensure recurring need, especially among high-mileage vehicles. -

Growth in Aftermarket and Online Retail Channels

Online auto parts retailers (e.g., RockAuto, Amazon, and AutoZone.com) dominate the drive belt market in 2026. Consumers increasingly favor convenience, competitive pricing, and customer reviews when purchasing parts. Aftermarket brands such as Gates, Dayco, and ACDelco maintain strong market share, offering cost-effective alternatives to OEM belts. Mobile-friendly platforms and AI-powered fitment tools enhance user experience and reduce purchase errors. -

OEM vs. Aftermarket Competition

While OEM Honda belts remain available through dealership networks and parts distributors, aftermarket manufacturers lead in market penetration due to lower prices and comparable performance. In 2026, many aftermarket belts incorporate improved materials (e.g., EPDM rubber) that offer longer life and resistance to heat and ozone, often surpassing the durability of original 2006 specifications. -

Consolidation of Inventory and Supply Chain Efficiency

As demand for 2006-specific parts stabilizes at lower levels, suppliers have optimized inventory through data-driven forecasting. Just-in-time logistics and warehouse automation help maintain availability while reducing overstock. Some smaller suppliers have exited the market, leading to industry consolidation around major players. -

Rise of DIY Maintenance Culture

The popularity of online repair tutorials (YouTube, repair manuals, and forums) has empowered more owners to replace drive belts themselves. This trend increases demand for user-friendly packaging, detailed installation guides, and tools bundles. Retailers that provide comprehensive support content see higher conversion rates. -

Environmental and Sustainability Considerations

In 2026, there is growing interest in sustainable automotive practices. Some manufacturers now offer eco-conscious drive belts made with recyclable materials or reduced environmental impact during production. While not yet mainstream, this trend may influence future product development. -

Potential for Obsolescence and Niche Market Shifts

As electric vehicles (EVs) grow in market share, the relevance of internal combustion engine (ICE) parts like drive belts diminishes overall. However, the 2006 Accord’s strong legacy ensures it remains a niche but viable segment. Specialty recyclers and salvage yards also play a larger role, offering used OEM belts for budget-conscious consumers.

Conclusion:

In 2026, the market for the 2006 Honda Accord drive belt is characterized by resilient demand from a shrinking but dedicated user base. Aftermarket dominance, digital retail expansion, and DIY trends shape the landscape, while supply chains adapt to long-tail demand. Though not a growth market, it remains stable and serviceable, reflecting the enduring quality and popularity of the 2006 Honda Accord.

Common Pitfalls When Sourcing a 2006 Honda Accord Drive Belt (Quality & IP Concerns)

When replacing the drive belt on a 2006 Honda Accord, avoiding common sourcing pitfalls is crucial for ensuring reliability, longevity, and vehicle safety. Two major areas of concern are product quality and intellectual property (IP) issues, which can lead to premature failure, engine damage, and legal complications.

Poor Quality Materials and Construction

One of the most frequent pitfalls is selecting a drive belt made from substandard materials or with inadequate construction. Low-quality belts may use inferior rubber compounds that degrade quickly when exposed to heat, oil, and ozone—common underhood conditions in the 2006 Accord’s K-series engine bay. These belts often lack sufficient tensile strength in the cord material, increasing the risk of stretching, cracking, or snapping. Belts that fail prematurely can lead to loss of power steering, coolant circulation, or alternator function, potentially causing engine overheating or stalling.

Lack of OEM or OE-Spec Compliance

Many aftermarket belts claim compatibility but do not meet the original equipment manufacturer (OEM) specifications for dimensions, tension, or rib profile. A belt that is slightly too long or too short can slip or place undue stress on pulleys and the tensioner. Non-OE-spec belts may also fail to align properly with the pulley grooves, accelerating wear on both the belt and associated components like the alternator and power steering pump. Always verify that the replacement belt adheres to Honda’s OE specifications (e.g., Gates K060868 or equivalent).

Counterfeit or IP-Infringing Products

Purchasing counterfeit belts—especially through unverified online marketplaces—poses a serious risk. These products often mimic well-known brands like Gates, Dayco, or Aisin but lack the proper quality control and material engineering. Counterfeit belts may infringe on trademarks and patents, violating intellectual property rights and offering no performance guarantee. These belts are typically mass-produced without adherence to safety or durability standards and can fail without warning, leading to roadside breakdowns or engine damage.

Inadequate Brand Verification and Sourcing Channels

Buying from unauthorized dealers or unclear supply chains increases the likelihood of receiving fake or degraded products. Reputable suppliers provide traceability, batch numbers, and clear branding. Without these, it’s difficult to verify authenticity. Always source from trusted automotive parts retailers, authorized distributors, or directly from manufacturer websites to ensure you receive a genuine, IP-compliant product backed by warranty and technical support.

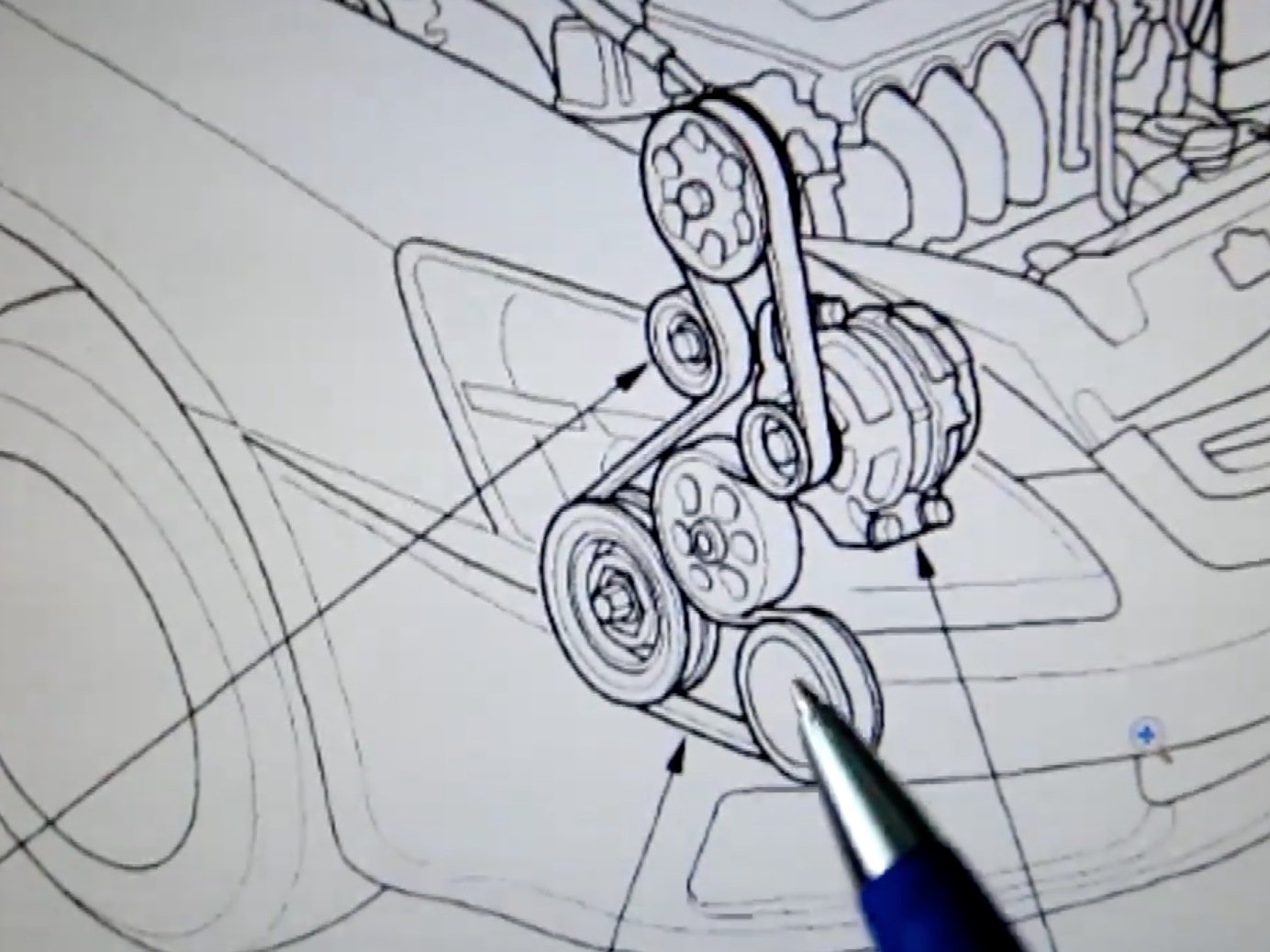

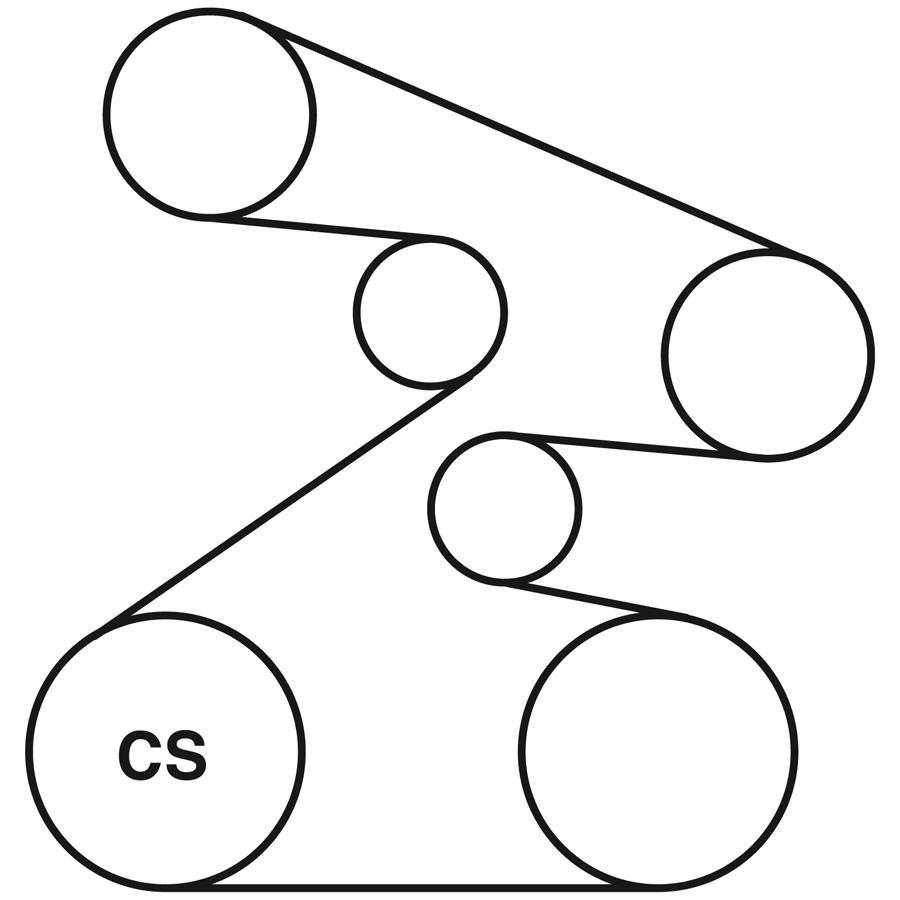

Ignoring Belt Type and Application Specifics

The 2006 Honda Accord may use different drive belt configurations depending on the engine (e.g., 2.4L vs. 3.0L V6) and whether it has A/C, power steering, or other accessories. Using a generic or incorrect belt type—such as a serpentine belt with the wrong number of ribs or length—can result in poor fitment and performance issues. Always match the belt to the specific engine code and routing diagram for your model.

H2: Logistics & Compliance Guide for 2006 Honda Accord Drive Belt

Proper logistics and compliance management are critical when sourcing, distributing, or replacing the drive belt (also known as the serpentine belt or accessory drive belt) for a 2006 Honda Accord. This guide outlines key considerations to ensure timely delivery, regulatory adherence, and product integrity.

H2: Logistics Considerations

-

Part Identification & Specifications:

- OEM Part Number: Confirm the correct OEM (Original Equipment Manufacturer) number. For the 2.4L (K24) engine, a common OEM number is 38920-RB0-003. For the 3.0L (J30) engine, it might be 38920-RLA-A01. Always verify using the VIN.

- Aftermarket Equivalents: Major brands (Gates, Dayco, ACDelco, Denso) offer compatible belts (e.g., Gates K060738, Dayco 5060738). Ensure cross-references are accurate.

- Critical Dimensions: Length (approx. 73.8″ / 1875mm for K24), width, rib count (typically 6 ribs), and material (EPDM – Ethylene Propylene Diene Monomer) are crucial for fitment and performance.

-

Sourcing & Procurement:

- Supplier Selection: Choose reputable suppliers (distributors, wholesalers, OEM) with proven quality control and traceability. Prioritize suppliers specializing in automotive parts.

- Inventory Management: Maintain adequate stock levels based on demand forecasts but avoid overstocking due to potential obsolescence. Implement FIFO (First-In, First-Out) rotation.

- Lead Times: Understand standard and expedited lead times from suppliers. Factor in potential delays from international shipping if sourcing globally.

-

Storage & Handling:

- Environment: Store belts in a cool, dry, dark place away from direct sunlight, ozone sources (motors, transformers), heat (>120°F/49°C), and chemicals (oils, solvents, acids).

- Packaging: Keep belts in original packaging until ready for use to protect from dust, moisture, and physical damage.

- Handling: Avoid kinking, twisting, or stretching the belt during handling. Never roll the belt; bend it gently if necessary.

-

Transportation:

- Packaging: Ensure secure packaging to prevent movement and damage during transit. Use sturdy boxes with cushioning.

- Temperature Control: Avoid prolonged exposure to extreme temperatures during shipping (e.g., no unventilated trucks in summer).

- Documentation: Include accurate packing slips, purchase orders, and any required certificates with shipments.

H2: Compliance Requirements

-

Quality Standards:

- ISO 9001: Suppliers should adhere to ISO 9001 quality management systems.

- OEM Specifications: Belts must meet or exceed Honda’s original specifications for material, construction, and performance (e.g., tensile strength, flexibility, heat/oil resistance).

- Industry Standards: Compliance with standards like SAE J1459 (Automotive V-belts) or specific EPDM belt standards is expected.

-

Environmental Regulations:

- REACH (EU): Ensure the belt material (rubber, additives) complies with EU REACH regulations restricting hazardous substances (SVHCs).

- RoHS (EU): While primarily for electronics, ensure no restricted substances (Pb, Cd, Hg, Cr6+, PBB, PBDE) are present in any belt components.

- TSCA (USA): Comply with the US Toxic Substances Control Act regarding chemical substances.

- Waste Disposal: Old belts are typically non-hazardous waste but check local regulations. Recycle where possible through tire/rubber recycling programs.

-

Safety & Performance:

- DOT Compliance: While not directly regulated like tires, belts contribute to vehicle safety (powering alternator, water pump, A/C). Failure can lead to breakdowns. Ensure belts are designed for the application’s load and speed.

- Fitment Accuracy: Providing the correct part number for the specific 2006 Accord engine variant (K24 or J30) is critical for safety and performance. Incorrect fitment can lead to belt failure, engine damage, or accessory failure.

-

Labeling & Documentation:

- Clear Part Numbering: Packaging and invoices must clearly display the correct OEM or aftermarket part number.

- Traceability: Maintain records linking batches/lot numbers to suppliers and shipments for potential recalls.

- Material Safety Data Sheet (MSDS/SDS): Suppliers should provide SDS for the belt material upon request, detailing composition and handling precautions.

-

Import/Export (If Applicable):

- HS Codes: Use correct Harmonized System codes (e.g., 4010.36 for V-belts of rubber) for customs declarations.

- Country-Specific Regulations: Comply with import regulations of the destination country (e.g., EPA rules in USA, CE marking implications in EU for components, though belts themselves aren’t CE marked).

- Duties & Tariffs: Understand applicable duties and tariffs for importing automotive parts.

Summary: Successful logistics and compliance for the 2006 Honda Accord drive belt require precise part identification, careful handling and storage, sourcing from reputable suppliers adhering to quality and environmental standards, and meticulous documentation. Prioritizing these factors ensures the right belt reaches the right place in optimal condition, meeting all regulatory requirements and supporting vehicle reliability. Always verify the specific part number using the vehicle’s VIN.

After evaluating various sourcing options for a 2006 Honda Accord drive belt, it is clear that multiple reliable avenues are available, each with its own advantages. Original Equipment Manufacturer (OEM) belts from authorized Honda dealerships offer guaranteed compatibility and quality, making them ideal for long-term reliability, though at a higher cost. Aftermarket alternatives from reputable brands such as Gates, ACDelco, or Dayco provide a cost-effective solution without significantly compromising performance or durability, especially when sourced from trusted retailers like AutoZone, O’Reilly Auto Parts, or online platforms such as Amazon and RockAuto.

Additionally, considering the age of the 2006 model, it is advisable to inspect related components such as the pulleys and tensioner during belt replacement to avoid premature failure. Sourcing a high-quality belt from a reputable supplier—whether OEM or aftermarket—ensures optimal engine performance and reduces the risk of breakdowns.

In conclusion, the best approach is to balance cost, quality, and reliability by selecting a well-reviewed drive belt from a trusted brand or dealer, ensuring proper fitment for the 2006 Honda Accord’s engine configuration (typically the 2.4L 4-cylinder or 3.0L V6). Regular maintenance and using dependable parts will extend the life of the vehicle’s accessory drive system.