The global market for electrical and power transmission products, including service entrance (SE) cables, is experiencing steady expansion driven by rising infrastructure investments, urbanization, and increased demand for reliable electrical distribution systems. According to Grand View Research, the global electrical wires and cables market was valued at USD 167.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by expanding construction activities, smart grid development, and strict regulatory standards promoting fire-safe and energy-efficient cabling solutions. Within this landscape, service entrance cables—critical for safely delivering power from utility lines to residential and commercial buildings—have become essential components in both new installations and retrofit projects. As demand for high-performance, code-compliant SE cables increases, several manufacturers have emerged as leaders in innovation, quality, and market reach. The following list highlights the top seven manufacturers shaping the SE cable segment through technical excellence, global distribution, and adherence to evolving industry standards.

Top 7 2 Service Entrance Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 2/0

Domain Est. 1994

Website: southwire.com

Key Highlights: Southwire Type SER, service entrance cable is primarily used to convey power from the service drop to the meter base and from the meter base to the ……

#2 Service Entrance Wire

Domain Est. 1995

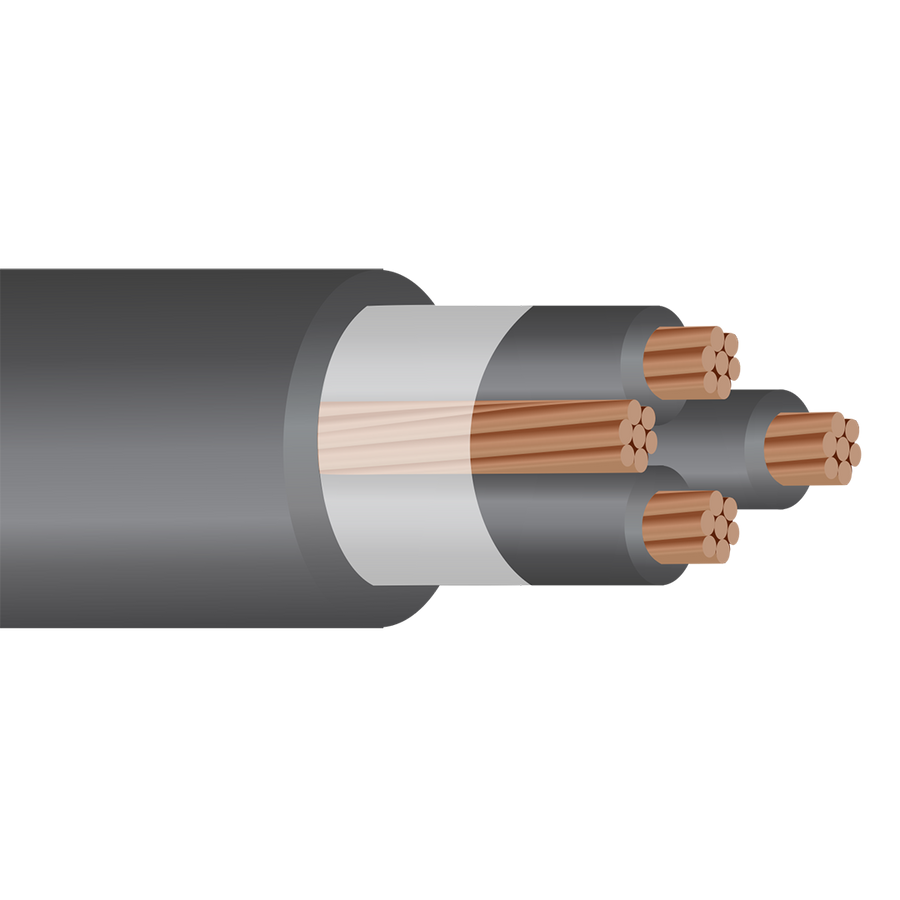

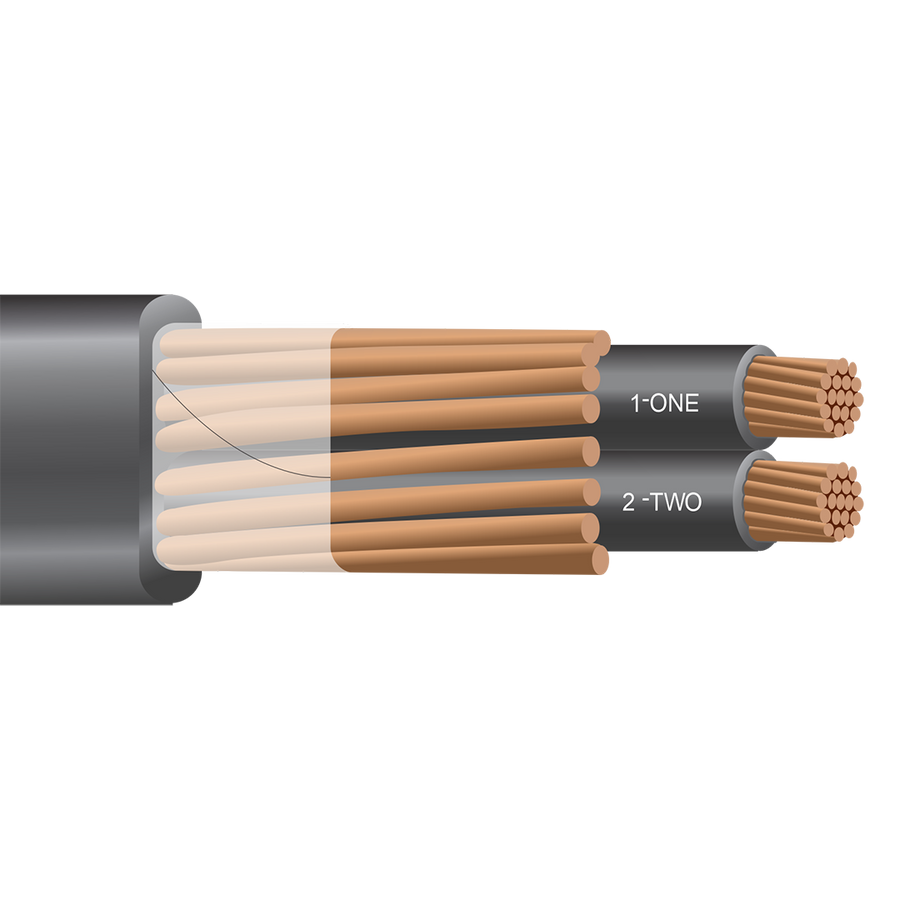

#3 SE-U

Domain Est. 1996

Website: servicewire.com

Key Highlights: SE-U, XHHW-2/PVC | Two conductors, stranded, insulated with heat and moisture resistant crosslinked polyethylene (type XHHW-2) and phase identified….

#4 Service Entrance Cables

Domain Est. 1996

Website: stateelectric.com

Key Highlights: 6–10 day deliveryService Entrance Cable, Stranded, 2-2-2 AWG, 2 Conductors, 3 Wire, Aluminum, Gray, 600 V Wire Aluminum – SEU2/3AL…

#5 2AWG, Stranded, Service Entrance Cable, Aluminum, 2 Conductor …

Domain Est. 1997

#6 Aluminum SE Cables

Domain Est. 1998 | Founded: 1923

Website: granitecityelectric.com

Key Highlights: Aluminum SE Cables – SER – NS-1 – NS-2 from Granite City Electric, the Northeast’s premiere electrical supply company since 1923….

#7 2

Domain Est. 2015

Website: wireandcableyourway.com

Key Highlights: In stock Free delivery over $1,000Aluminum SEU cable is primarily used as panel feeder in multiple unit dwellings and for branch circuits. Maximum operating temperature is not to e…

Expert Sourcing Insights for 2 Service Entrance Cable

H2: Market Trends for 2-Service Entrance Cable (2026 Outlook)

The market for 2-service entrance cable—specifically defined as electrical cable used to connect utility power lines to residential or commercial building service panels—is poised for notable evolution by 2026. Driven by shifts in construction practices, regulatory standards, energy demands, and technological advancements, several key trends are shaping the trajectory of this sector.

-

Increased Demand from Residential and Light Commercial Construction

The sustained growth in new housing starts and renovation projects across North America, particularly in the U.S., is a primary driver for 2-service entrance cable demand. As urbanization continues and housing shortages persist, builders are increasingly relying on standardized, code-compliant electrical components. The 2-service entrance cable, typically used in single-family homes and duplexes, benefits from this construction boom. By 2026, demographic trends such as remote work and multi-generational living are expected to further stimulate demand for new builds and electrical upgrades—favoring cost-effective and readily available cable solutions. -

Adoption of Energy-Efficient and Smart Building Standards

Building codes are evolving to support energy efficiency and smart infrastructure. The 2026 International Energy Conservation Code (IECC) and National Electrical Code (NEC) updates may require improved grounding, surge protection, and compatibility with solar integration and electric vehicle (EV) charging systems. As a result, 2-service entrance cables may need to meet higher insulation standards or support dual-service configurations (e.g., main + solar sub-panel). While the cable itself may not change drastically, its installation context will increasingly involve integration with renewable energy systems, boosting demand for compliant and future-ready configurations. -

Material and Supply Chain Shifts

Copper remains the dominant conductor material in 2-service entrance cables due to its conductivity and durability. However, ongoing volatility in copper prices and supply chain constraints may encourage the exploration of aluminum or copper-clad aluminum (CCA) alternatives, especially in cost-sensitive markets. By 2026, manufacturers could offer more hybrid or optimized designs to balance performance and cost. Additionally, regional reshoring of electrical component manufacturing—driven by U.S. infrastructure investments (e.g., IIJA, IRA)—may improve supply chain resilience and reduce lead times for service entrance cables. -

Sustainability and Regulatory Pressures

Environmental regulations are pushing manufacturers toward recyclable materials and reduced environmental impact. The 2026 market may see increased use of low-smoke zero-halogen (LSZH) jackets or PVC-free insulation in service cables, particularly in jurisdictions with green building mandates. Moreover, product labeling and traceability requirements may become more stringent, favoring suppliers with transparent, sustainable sourcing practices. -

Digitalization and Distribution Channels

Digital procurement platforms and B2B e-commerce are transforming how contractors and electricians source materials. By 2026, distributors are likely to offer enhanced digital catalogs, real-time inventory tracking, and integration with project management software—making it easier to specify and procure 2-service entrance cables. This trend will benefit suppliers with strong online presence and agile logistics networks.

In summary, the 2-service entrance cable market in 2026 will be shaped by construction growth, evolving electrical codes, material innovation, and digital transformation. While the product remains a fundamental component of building electrical systems, its role is expanding within the broader context of smart, sustainable, and resilient infrastructure. Manufacturers and distributors who anticipate these shifts will be best positioned to capture market share in the coming years.

Common Pitfalls When Sourcing 2 Service Entrance Cable (Quality, IP)

Sourcing Service Entrance Cable (SEC), especially 2-wire configurations, requires careful attention to quality and Ingress Protection (IP) ratings to ensure safety, compliance, and long-term performance. Overlooking key factors can lead to costly failures, safety hazards, and non-compliance. Below are common pitfalls to avoid:

Inadequate Quality Verification

One of the most frequent issues is assuming all cables meet required standards without proper verification. Low-quality SEC may use substandard conductors, insulation, or jacketing materials that degrade quickly under environmental stress. Buyers often fail to request or review certifications such as UL 44, UL 83, or NEC Article 338 compliance, leading to the purchase of cables unsuitable for outdoor or high-load applications.

Ignoring Environmental Ratings

Service entrance cables are exposed to harsh conditions, including moisture, UV radiation, and temperature extremes. A common mistake is selecting cables without appropriate environmental protection. For instance, using a cable not rated for direct burial or sunlight resistance can result in premature failure. Always confirm the cable is rated for wet locations and has UV-stabilized jacketing.

Misunderstanding IP Ratings

Ingress Protection (IP) ratings are critical for outdoor or exposed installations, yet they are often misunderstood or overlooked when sourcing SEC. Service entrance cables typically terminate in enclosures or service panels where IP protection matters. Using a cable gland or entry system with insufficient IP rating (e.g., IP54 vs. required IP66) can allow dust and water ingress, compromising the entire electrical system. Ensure compatibility between the cable entry method and the required IP level for the installation environment.

Overlooking Mechanical Durability

Some low-cost cables skimp on mechanical protection, making them vulnerable to damage during installation or from environmental factors like rodent activity or abrasion. Cables without sufficient jacket thickness or armor (where needed) may fail prematurely. Verify the cable’s crush resistance and tensile strength, especially for aerial or underground runs.

Failing to Consider Local Codes and Approvals

Electrical codes vary by region, and using non-compliant SEC can lead to failed inspections or safety risks. A common pitfall is sourcing cables that meet generic standards but lack local certification (e.g., CSA in Canada, CE in Europe, or specific utility requirements). Always confirm the cable meets the relevant national and local electrical codes for the installation site.

Assuming 2-Wire Configurations Meet All Needs

While 2-wire SEC is common for basic single-phase services, assuming it’s sufficient without evaluating the load and grounding requirements can be dangerous. Improper grounding or neutral bonding due to incorrect cable configuration can create shock hazards and equipment damage. Ensure the cable assembly includes proper grounding conductors if required, or that grounding is achieved through alternate approved means.

Choosing Based Solely on Price

Opting for the lowest-cost option often leads to compromises in material quality, longevity, and safety. Cheap cables may use aluminum instead of copper or have thinner insulation, increasing resistance and fire risk. Invest in high-quality, certified cables from reputable suppliers to avoid downtime, replacements, and potential liability.

By addressing these pitfalls proactively—verifying quality certifications, understanding IP requirements, and ensuring code compliance—buyers can source reliable, safe, and durable Service Entrance Cable for long-term performance.

Logistics & Compliance Guide for 2 Service Entrance Cable

Overview

Service Entrance (SE) Cable rated for 2 conductors is a critical component in electrical distribution systems, commonly used to deliver power from utility lines to a building’s main service panel. Proper logistics handling and compliance with national and local codes are essential for safety, performance, and regulatory approval.

Regulatory Standards & Compliance

-

National Electrical Code (NEC) Compliance:

2-conductor SE cables must comply with Article 338 of the NEC, which governs the installation of service-entrance conductors and cables. Key requirements include proper ampacity ratings, insulation types (e.g., Type SE, USE, or SER), and temperature ratings (typically 60°C, 75°C, or 90°C). -

UL Listing:

All 2-conductor SE cables must be UL Listed under product category “Service-Entrance Cable” (File Number QAWZ). This ensures compliance with safety standards for construction, insulation, and flame resistance. -

NEC Ampacity Requirements:

Conductors must be sized according to load calculations per NEC Table 310.16. For 2-conductor SE cable, ensure proper derating when bundled or exposed to high ambient temperatures. -

Weather and UV Resistance:

When installed outdoors, SE cables must be rated for direct burial (USE-2) or have a sunlight-resistant jacket (marked “Sunlight Resistant” per NEC 338.10).

Packaging & Handling Requirements

-

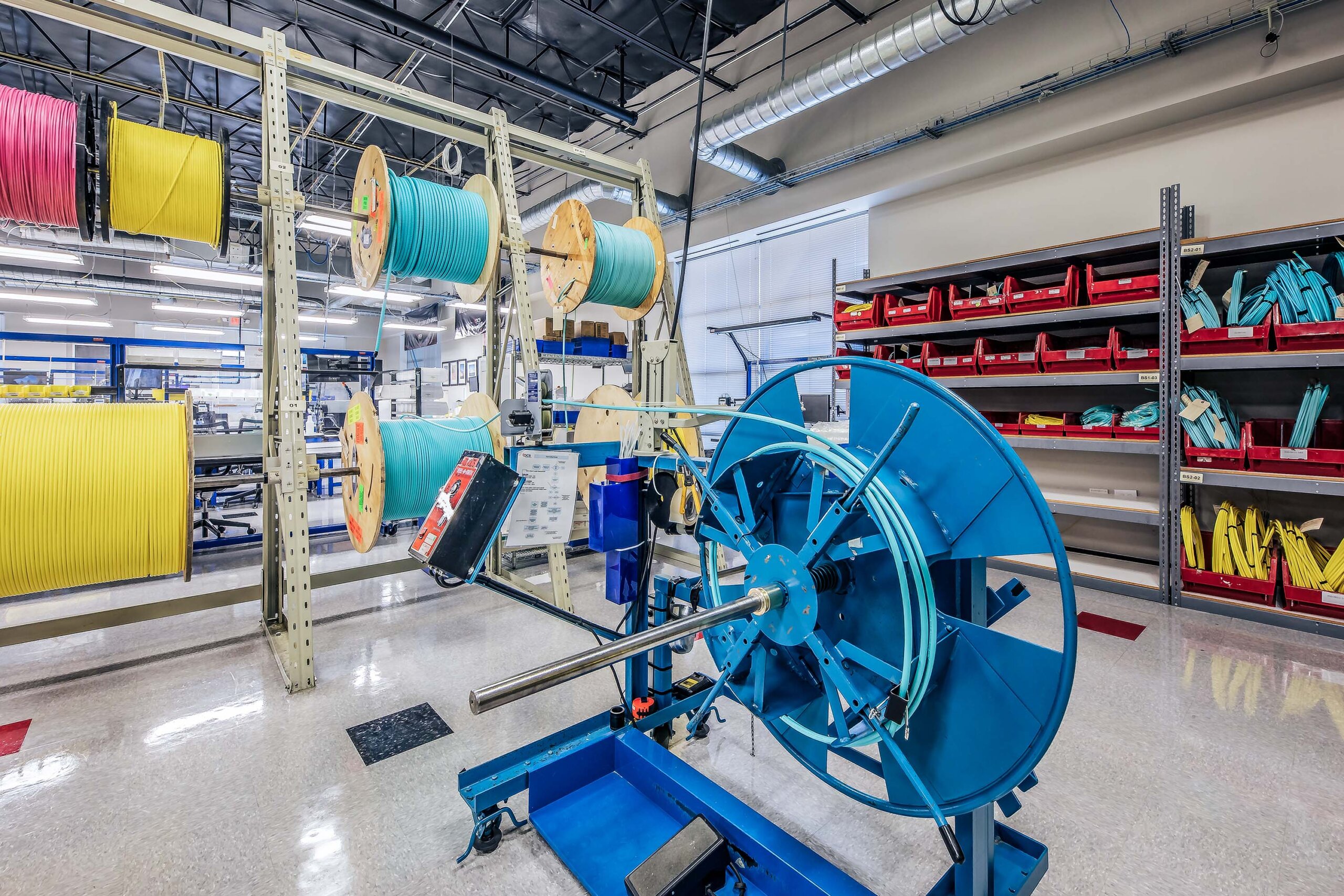

Coiling & Spooling:

2-conductor SE cable is typically shipped on reels or in coils. Avoid sharp bends; minimum bending radius is 8 times the cable diameter. -

Storage Conditions:

Store in a dry, temperature-controlled environment (40°F to 100°F). Protect from direct sunlight, moisture, and chemical exposure to prevent jacket degradation. -

Handling During Transport:

Use proper lifting equipment (e.g., cable reel lifters) to prevent damage. Never drag reels on the ground. Secure reels during transport to avoid shifting.

Installation Best Practices

-

Support & Securing:

Per NEC 338.7, SE cables must be securely fastened at intervals not exceeding 30 inches and within 12 inches of service heads or raceway connections. -

Drip Loops:

Install drip loops at service entry points to prevent water from running along the cable into service equipment. -

Conduit Use:

While not always required, SE cables must be protected from physical damage where exposed. Use Schedule 80 PVC or EMT conduit when passing through walls or subject to impact. -

Grounding & Bonding:

For SER (Service Entrance Cable, Round), the concentric neutral or bond wire must be properly bonded to the grounding system per NEC Article 250.

Shipping & Receiving Logistics

-

Ordering Specifications:

Clearly specify gauge (e.g., 2/0 AWG), insulation type (e.g., SEU, USE-2), voltage rating (typically 600V), and length. Confirm reel size and weight for handling needs. -

Inspection Upon Delivery:

Inspect packaging for damage. Check cables for cuts, crushed jackets, or kinks. Reject visibly damaged shipments and document with photos. -

Inventory Management:

Label reels with part number, length, and date received. Rotate stock using FIFO (First In, First Out) to avoid aging.

Environmental & Safety Compliance

-

RoHS & REACH:

Confirm cable materials comply with RoHS (Restriction of Hazardous Substances) and REACH regulations if required for project specifications or regional mandates. -

Recycling & Disposal:

Copper and aluminum conductors are recyclable. Follow local regulations for disposal of cable jackets and insulation materials.

Documentation & Certification

-

Submittal Requirements:

Provide manufacturer cut sheets, UL certification, and NEC compliance statements during project submittal. -

Job Site Records:

Retain delivery tickets, inspection reports, and installation logs for audit and inspection purposes.

Final Inspection & Testing

-

Visual Inspection:

Ensure no nicks, abrasions, or improper terminations exist prior to energizing. -

Continuity & Ground Testing:

Verify conductor continuity and grounding integrity using approved test equipment. -

AHJ Approval:

Coordinate with the Authority Having Jurisdiction (AHJ) for final electrical inspection prior to commissioning.

By adhering to this guide, contractors and project managers can ensure safe, compliant, and efficient handling and installation of 2-conductor Service Entrance Cables.

Conclusion for Sourcing Two Service Entrance Cables

In conclusion, sourcing two service entrance cables requires careful consideration of electrical code compliance, load requirements, environmental conditions, and long-term reliability. After evaluating available options, it is essential to select cables that meet or exceed local and national electrical standards (such as NEC Article 230 in the U.S.) and are appropriately rated for the expected voltage, amperage, and installation method—whether overhead (SEU, SER) or underground (USE-2, XHHW-2 in conduit).

Sourcing cables from reputable manufacturers and certified suppliers ensures product quality, safety, and warranty coverage. Additionally, considering factors such as conductor material (copper vs. aluminum), insulation type, and ease of installation will contribute to a cost-effective and durable electrical service setup. Procuring both cables simultaneously from the same batch can also help maintain consistency in performance and simplify installation.

Ultimately, properly sourced service entrance cables ensure a safe, efficient, and code-compliant power supply for the structure, minimizing the risk of failures, outages, or hazardous conditions. It is recommended to consult with a licensed electrician or engineer during the selection and installation process to confirm that all project-specific requirements are met.