The global submersible pump market is witnessing robust growth, driven by increasing demand across residential, agricultural, and industrial sectors. According to Grand View Research, the market was valued at USD 10.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by rising infrastructure investments, expanding irrigation needs, and growing reliance on groundwater resources, particularly in emerging economies. Within this dynamic landscape, 1-horsepower (1Hp) submersible pumps have emerged as a critical category—offering optimal balance between performance, energy efficiency, and affordability. Widely adopted for domestic water supply, borewell dewatering, and small-scale irrigation, the demand for reliable 1Hp units has spurred intense competition among manufacturers focused on innovation, durability, and cost-effectiveness. This evolving market environment makes it essential to identify the leading manufacturers shaping the future of submersible pumping solutions.

Top 10 1Hp Submersible Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Borewell Submersible Pumps Manufacturer

Domain Est. 2001

Website: lubipumps.com

Key Highlights: Leading borewell submersible pump manufacturer for more than 50 years, that offer enduring and reliability for a range of industrial and agriculture ……

#2 Grundfos USA

Domain Est. 1995

Website: grundfos.com

Key Highlights: The full range supplier of pumps and pump solutions. As a renowned pump manufacturer, Grundfos delivers efficient, reliable, and sustainable solutions all ……

#3 Pentair Simer 2865G 1 HP 4″ Submersible Well Pump

Domain Est. 1996

Website: pentair.com

Key Highlights: Submersible well pumps provide the optimal amount of water pressure for residential use. View the Pentair Simer 2865G 1 HP 4″ Submersible Well Pump here….

#4 Submersible pumps

Domain Est. 1998

Website: dabpumps.com

Key Highlights: Pulsar Dry by DAB is a 5-inch submersible or surface multi stage impeller monoblock pump for clean water to increase water pressure, gardening and ……

#5 Zoeller Pump Company

Domain Est. 1999

Website: zoellerpumps.com

Key Highlights: Explore Zoeller Pumps for reliable and efficient pumping solutions. Find a wide range of quality pumps for residential and commercial applications….

#6 Submersible Well Pumps

Domain Est. 2009

Website: franklinwater.com

Key Highlights: Franklin Electric offers a variety of submersible pumps designed for the movement of water providing superior performance for many different applications….

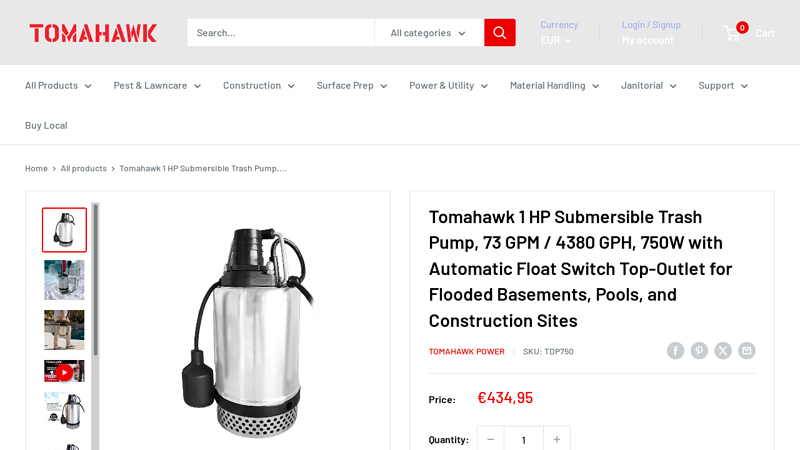

#7 Tomahawk 1 HP Submersible Trash Pump, 73 GPM / 4380 GPH …

Domain Est. 2012

Website: tomahawk-power.com

Key Highlights: In stock $14.99 deliveryTackle high-volume water removal with ease using the Tomahawk TDP750 Submersible Pump. Built with a heavy-duty 1 HP motor and capable of moving up to 4,380 …

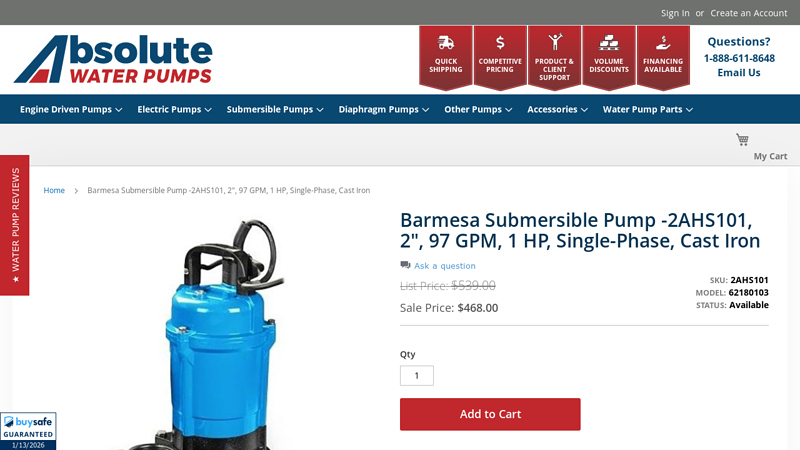

#8 2AHS101, 2″, 97 GPM, 1 HP, Single

Domain Est. 2012

Website: absolutewaterpumps.com

Key Highlights: Barmesa Submersible Pump -2AHS101, 2″, 97 GPM, 1 HP, Single-Phase, Cast Iron ; Fuel Type, Electric ; Engine/Motor Type, Oil Filled ; Starting System, NA….

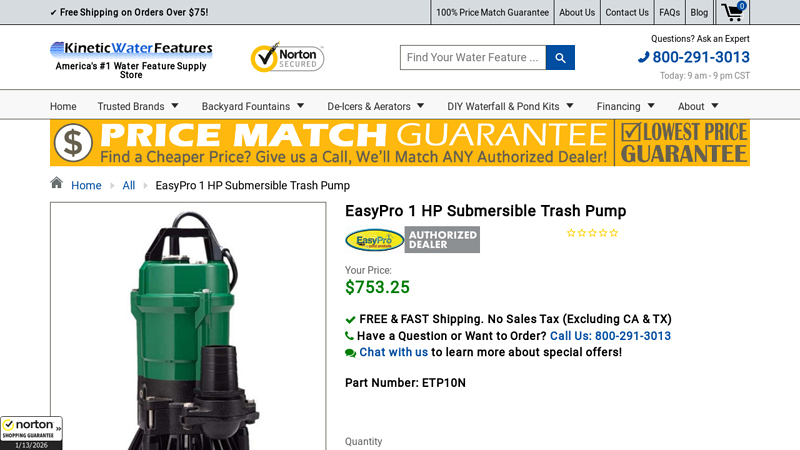

#9 EasyPro 1 HP Submersible Trash Pump

Domain Est. 2017

Website: kineticwaterfeatures.com

Key Highlights: In stock Rating 5.0 5 This submersible trash pump is designed to handle sand, solids, leaves, algae, and other debris of up to 3/8″ x 1″ in size. It is perfect for waterfalls whe…

#10 1HP Well Pumps & Submersible Pumps

Domain Est. 2022

Expert Sourcing Insights for 1Hp Submersible

H2: Projected 2026 Market Trends for 1HP Submersible Pumps

The global market for 1HP submersible pumps is poised for significant transformation by 2026, driven by technological advancements, expanding infrastructure needs, and increasing emphasis on water sustainability. Several key trends are expected to shape the industry landscape:

-

Rising Demand in Agriculture and Rural Electrification

With growing global food demands and government-led irrigation initiatives—particularly in emerging economies across Asia, Africa, and Latin America—the agricultural sector will remain a primary driver for 1HP submersible pumps. These pumps are ideal for medium-depth borewells and small-to-medium farms due to their balance of power, efficiency, and cost. India’s PM-KUSUM scheme and similar rural electrification programs are expected to accelerate adoption, especially with solar-powered variants. -

Growth of Solar-Powered 1HP Submersible Pumps

By 2026, solar-powered 1HP submersible pumps are projected to capture a larger market share. Declining solar panel costs, government subsidies, and off-grid energy needs in remote areas are fueling this shift. Manufacturers are increasingly integrating MPPT (Maximum Power Point Tracking) technology and brushless DC (BLDC) motors to improve efficiency and reliability, making solar pumps a viable alternative to grid- or diesel-powered systems. -

Smart and IoT-Enabled Pumping Systems

Digitalization is entering the submersible pump sector, with smart pumps equipped with IoT sensors for remote monitoring, predictive maintenance, and water level detection. By 2026, leading manufacturers are expected to offer connected 1HP models that provide real-time data on pump performance, energy consumption, and dry-run protection. This trend is particularly strong in commercial and municipal applications, where operational efficiency and uptime are critical. -

Focus on Energy Efficiency and Regulatory Standards

Global push for energy conservation will drive demand for IE3 and IE4 efficiency-rated 1HP submersible pumps. Regulatory frameworks such as MEPS (Minimum Energy Performance Standards) in countries like India, the U.S., and EU members will compel manufacturers to innovate in motor design, materials, and hydraulic efficiency. Premium efficiency pumps may command higher prices but offer long-term savings, appealing to both end-users and utilities. -

Expansion in Urban and Municipal Water Supply

Rapid urbanization, especially in Southeast Asia and Africa, will increase demand for reliable water extraction and distribution systems. 1HP submersible pumps are widely used in community water supply schemes, sewage handling, and building services. Municipal tenders and public-private partnerships will create steady procurement opportunities. -

Competitive Landscape and Regional Shifts

Asia-Pacific, led by India and China, will remain the largest market for 1HP submersible pumps due to agricultural dependence and government infrastructure spending. However, increased local manufacturing and technological upgrades are expected in Africa and Latin America. Key players such as Kirloskar, CRI Pumps, Grundfos, and KSB are likely to expand their regional footprint through localized production and distribution networks. -

Material and Design Innovations

By 2026, manufacturers will increasingly adopt corrosion-resistant materials (e.g., stainless steel, advanced thermoplastics) and modular designs to enhance durability and reduce maintenance. These improvements will be crucial in challenging environments such as saline aquifers or high-sediment wells.

In conclusion, the 1HP submersible pump market in 2026 will be characterized by smarter, greener, and more efficient solutions. The convergence of renewable energy integration, digital monitoring, and global water security concerns will position the 1HP segment as a cornerstone of sustainable water management across residential, agricultural, and municipal sectors.

Common Pitfalls When Sourcing a 1HP Submersible Pump (Quality & IP Rating)

Sourcing a 1HP submersible pump can be straightforward, but overlooking critical quality and Ingress Protection (IP) factors often leads to premature failure, safety hazards, and costly replacements. Avoid these common pitfalls:

Inadequate IP Rating for Submersion Depth and Environment

- Pitfall: Assuming any “submersible” pump has sufficient protection. Many lower-quality pumps may claim submersibility but only have an IP rating like IPX6 (protected against powerful water jets) or IP67 (protected against temporary immersion up to 1m for 30 min), which is insufficient for continuous deep submersion.

- Consequence: Water ingress into the motor or electrical components, leading to short circuits, corrosion, and catastrophic failure, especially if the pump operates below 1 meter or in dirty/silty water.

- Solution: Demand a minimum IP68 rating. This signifies the pump is dust-tight (6) and protected against continuous immersion in water under pressure (8) at a specified depth (e.g., IP68 10m). Verify the depth specification provided by the manufacturer matches your application (e.g., well depth, sump depth).

Compromised Seals and Mechanical Integrity

- Pitfall: Overlooking the quality and design of critical seals (shaft seal, cable entry gland, housing joints). Low-cost pumps often use inferior materials (e.g., basic rubber instead of Viton) or inadequate sealing designs (single vs. double mechanical seals).

- Consequence: Premature seal failure allows water to enter the motor, even with a high IP rating on the housing. This causes lubricant washout, bearing failure, and motor burnout. Poor housing materials (thin cast iron, low-grade plastic) crack under pressure or corrosion.

- Solution: Specify pumps with double mechanical seals (often with an oil-filled barrier chamber) for enhanced protection. Verify seal material suitability for your water type (clean, dirty, abrasive). Inspect housing for robust construction and corrosion-resistant materials (stainless steel options exist for harsh environments).

Overstated or Unverified Performance Specifications

- Pitfall: Relying solely on manufacturer-provided performance curves (flow rate vs. head) without considering real-world conditions or potential exaggeration, especially with lesser-known brands. “1HP” might refer to input power, not actual output hydraulic power.

- Consequence: The pump fails to deliver the required flow or lift water to the necessary height, leading to inadequate system performance. Efficiency might be much lower than expected, increasing energy costs.

- Solution: Source from reputable brands with independent test certifications (e.g., HI – Hydraulic Institute standards). Cross-check performance data with known reliable suppliers. Consider the pump’s efficiency rating (higher is better) and ensure the “1HP” refers to the motor’s rated output power. Account for pipe friction, fittings, and static lift in your system calculations.

Poor Quality Motor and Electrical Components

- Pitfall: Ignoring motor construction details. Low-quality motors may use undersized windings, poor insulation (e.g., Class B instead of Class F/H), inadequate cooling (relying solely on surrounding water), or substandard cable (incorrect gauge, poor jacketing).

- Consequence: Motor overheats, especially during frequent cycling or in warmer water, leading to insulation breakdown and burnout. Poor cable quality leads to abrasion, water ingress at the entry point, or voltage drop.

- Solution: Ensure the motor has high-temperature insulation (Class F or H) and is designed for continuous submersion cooling. Verify the power cable is the correct gauge for the distance and has a robust, oil-resistant jacket (e.g., Neoprene, EPDM). Look for built-in thermal overload protection.

Lack of Certifications and Documentation

- Pitfall: Purchasing pumps without essential safety and quality certifications, particularly for the region of use.

- Consequence: Safety risks (electrical shock, fire), potential non-compliance with local regulations, voided warranties, and difficulty proving performance or safety claims.

- Solution: Require relevant certifications: CE (Europe), UL/cUL (North America), RoHS, ISO 9001 (quality management). Ensure documentation includes clear performance curves, IP rating, installation manual, and warranty terms.

By proactively addressing these pitfalls related to quality and IP rating, you ensure reliable, safe, and efficient operation of your 1HP submersible pump, maximizing its lifespan and minimizing total cost of ownership.

Logistics & Compliance Guide for 1HP Submersible Pump

Product Overview

The 1HP submersible pump is an electric water pump designed for underwater operation, commonly used in residential, agricultural, and light industrial applications such as well water extraction, sump pumping, and drainage. Key specifications typically include a 1 horsepower motor, 115V or 230V power supply, stainless steel or thermoplastic construction, and various flow and head ratings depending on model.

Packaging Requirements

- Primary Packaging: Unit sealed in protective plastic wrap with foam inserts to prevent mechanical damage.

- Secondary Packaging: Sturdy corrugated cardboard box with internal dividers for multiple units. Box must be moisture-resistant.

- Labeling: Each package must include:

- Product name and model number

- Manufacturer name and contact information

- Input voltage and power rating (e.g., 1HP, 115/230V)

- IP (Ingress Protection) rating (e.g., IP68)

- Safety warnings and handling instructions

- Country of origin

- Serial or batch number for traceability

Shipping & Transportation

- Mode of Transport: Suitable for road, rail, sea, and air freight. Choose non-hazardous classification.

- Palletization: Stack up to 10–12 boxes per standard pallet (48” x 40”) secured with stretch wrap and corner boards.

- Weight Limits: Ensure total pallet weight does not exceed 1,500 lbs for safe handling.

- Environmental Conditions: Protect from prolonged exposure to moisture, extreme temperatures (>120°F or <14°F), and direct sunlight during transit.

- Handling: Use mechanical lifting equipment; do not drop or roll pallets.

Import & Export Compliance

- HS Code: Typically classified under 8413.70 (Other pumps for liquids, submersible). Confirm with local customs authority.

- Export Controls: Generally not subject to ITAR or EAR restrictions but verify based on destination country.

- Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (if required for preferential tariffs)

- Restricted Destinations: Check for import bans or licensing requirements in embargoed or sanctioned countries.

Regulatory Approvals & Certifications

- Electrical Safety:

- North America: UL/cUL Listed (UL 507 or UL 1076 for submersible pumps)

- Europe: CE Marking per Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU

- UK: UKCA Marking (post-Brexit)

- Energy Efficiency: Compliant with DOE (U.S.) or Ecodesign (EU) standards where applicable.

- Environmental:

- RoHS compliant (Restriction of Hazardous Substances)

- REACH SVHC declaration if requested

- Water Safety: NSF/ANSI 61 or NSF/ANSI 372 certification if intended for potable water use.

Customs Clearance Procedures

- Ensure all documentation matches product specifications exactly.

- Declare accurate HTS code and value to avoid delays or penalties.

- Provide test reports or certificates upon customs request.

- Use a licensed customs broker for complex shipments or high-value consignments.

Storage Guidelines

- Store in a dry, temperature-controlled environment (40°F–90°F).

- Keep away from corrosive chemicals and direct sunlight.

- Stack no more than 5 layers high on pallets to avoid crushing.

- Rotate stock using FIFO (First In, First Out) method.

End-of-Life & Disposal

- Recycling: Separate components (copper windings, steel housing, plastic parts) for recycling.

- Hazardous Waste: No hazardous materials under normal conditions, but follow local e-waste regulations.

- Compliance: Adhere to WEEE (EU) or state-level e-waste rules (e.g., California).

Additional Notes

- Verify regional voltage and plug compatibility for plug-and-play models.

- Include multilingual instruction manuals where required (e.g., French in Canada, Spanish in Latin America).

- Maintain records of compliance certifications for at least 5 years.

Note: Always consult local regulations and update compliance documentation as standards evolve.

Conclusion for Sourcing 1HP Submersible Pumps

After a thorough evaluation of technical specifications, market availability, supplier reliability, and cost-effectiveness, sourcing a 1HP submersible pump should prioritize durability, energy efficiency, and suitability for the intended application—whether for domestic water supply, agricultural irrigation, or light industrial use. Key factors to consider include pump material (such as stainless steel or thermoplastic), head capacity, flow rate, cable length, and compliance with relevant quality standards (e.g., ISO, CE, or local certifications).

Sourcing from reputable manufacturers or suppliers with proven after-sales support ensures long-term performance and reduces maintenance costs. While cost is an important consideration, opting for the lowest-priced option may compromise reliability and efficiency. Therefore, a balanced approach that considers total cost of ownership, warranty, and supplier reputation is recommended.

In conclusion, the ideal sourcing strategy for a 1HP submersible pump involves selecting a high-quality, efficient model from a trusted supplier, tailored to the specific operational requirements, ensuring reliable performance, minimal downtime, and optimal return on investment.