The global wire mesh market is experiencing robust growth, driven by increasing demand across construction, agriculture, filtration, and industrial sectors. According to a 2023 report by Mordor Intelligence, the market was valued at approximately USD 41.5 billion in 2022 and is projected to grow at a CAGR of over 5.2% from 2023 to 2028. This expansion is fueled by rising infrastructure development, particularly in emerging economies, along with the growing need for efficient material separation and protective barriers in industrial applications. As demand for high-quality 1/8-inch wire mesh—a popular gauge for fencing, reinforcement, and filtration—continues to rise, a select group of manufacturers are leading the charge in innovation, production capacity, and global reach. Based on market presence, product quality, and industry reputation, the following nine companies represent the top manufacturers in the 1/8-inch wire mesh segment.

Top 9 1/8 In Wire Mesh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ACS Industries

Domain Est. 1997

Website: acsindustries.com

Key Highlights: Leading vertically integrated wire mesh manufacturer specializing in knitted wire mesh, woven metal mesh & critical components for green energy, ……

#2 Metals Supplier & Service Center

Domain Est. 1997

Website: sss-steel.com

Key Highlights: Triple-S Steel is one of the largest metals distributor and service center in North and South America. Whether your project is large or small, local or global,…

#3 Steel 1″ Wire Mesh 1/8″

Domain Est. 2005

Website: metalsrus.ca

Key Highlights: In stockA durable, versatile steel sheet designed with a mesh pattern for use in a variety of industrial, construction, and manufacturing applications….

#4 Steel braided wire mesh

Domain Est. 2023

Website: en.dniprometyz.com

Key Highlights: Steel braided wire mesh ; Diameter of wire. 1,8 — 3,0 mm ; Wire mesh No.(cell size). 35 — 60 mm ; Cell type. Square ; Steel grade. St1, St2 of all degrees of ……

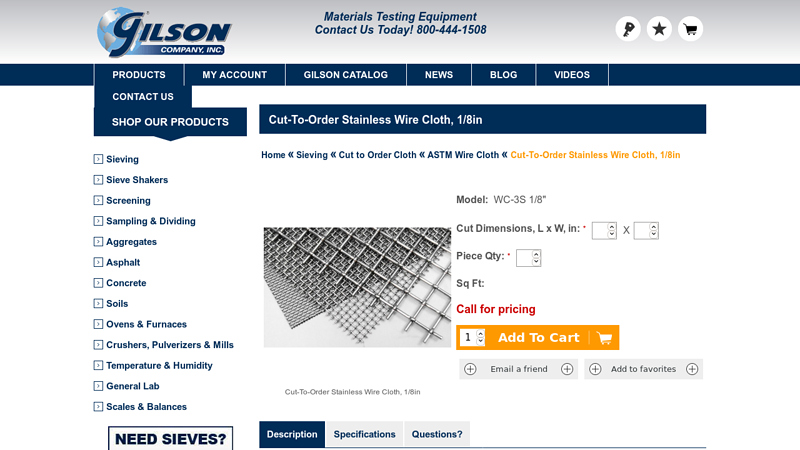

#5 Cut

Domain Est. 1995

Website: globalgilson.com

Key Highlights: 30-day returns1/8″ (3.18mm) stainless steel testing-grade woven-wire sieve cloth meets ASTM E11 and AASHTO M 92 opening size requirements and is the same quality used in ……

#6 Welded & Woven Wire Cloth

Domain Est. 1996

Website: brown-campbell.com

Key Highlights: … Wire Mesh Tables · Square Mesh (1″ to 4″ Mesh) · Square Mesh (4-1/2″ Mesh to 14″ Mesh) · Square Mesh (15″ Mesh to 38″ Mesh) · Square Mesh (40″ Mesh to 400″ Mesh) ……

#7 Galvanized Hardware Cloth Supplier

Domain Est. 1999

Website: marcospecialtysteel.com

Key Highlights: Galvanized Wire Mesh Stock ; 27GA Hardware Cloth, 1/8″x 1/8″ – 24″x 100′, Galvanized After Weaving ; 27GA Hardware Cloth, 1/8″x 1/8″ – 36″x 100′, Galvanized After ……

#8 Wire Mesh Technical Information by IWM

Domain Est. 2015

Website: iwmesh.com

Key Highlights: IWM is in continuous production of plain weave wire mesh constructed of aluminum, low carbon steel, stainless steel, commercial bronze and copper alloys….

#9 Seboss Hardware Cloth Store

Domain Est. 2022

Website: sebossfence.com

Key Highlights: Produce and sell 1/2in opening ,1/4in opening weld mesh and steel chain link fence fabric hardware cloth/wire mesh, series English dimension, ……

Expert Sourcing Insights for 1/8 In Wire Mesh

H2: 2026 Market Trends for 1/8 Inch Wire Mesh

The global market for 1/8 inch wire mesh is expected to experience steady growth and transformation by 2026, driven by increasing demand across construction, industrial filtration, agricultural, and security applications. As industries evolve and sustainability becomes a central focus, several key trends are shaping the trajectory of the 1/8 inch wire mesh sector.

-

Rising Demand in Construction and Infrastructure

With global infrastructure development accelerating—particularly in emerging economies—the use of 1/8 inch wire mesh in concrete reinforcement, fencing, and protective barriers is expanding. Urbanization, smart city projects, and government investments in public works are fueling demand, especially in regions such as Asia-Pacific and Africa. -

Growth in Industrial and Filtration Applications

The 1/8 inch mesh size is ideal for medium-duty filtration and separation processes in industries like mining, food processing, and chemical manufacturing. As automation and process efficiency improve, the need for durable, corrosion-resistant mesh solutions is rising. Stainless steel and galvanized variants are becoming preferred for their longevity and performance. -

Expansion in Agricultural and Horticultural Uses

Farm automation and modern greenhouse technologies are increasing the adoption of wire mesh for crop protection, animal enclosures, and ventilation systems. The 1/8 inch mesh offers a balance between strength and airflow, making it suitable for pest control and climate management in sustainable farming practices. -

Emphasis on Material Innovation and Sustainability

Manufacturers are investing in eco-friendly production methods and recyclable materials. The shift toward green building standards (e.g., LEED certification) is encouraging the use of sustainable wire mesh products. Additionally, advancements in coating technologies enhance corrosion resistance, reducing maintenance and lifecycle costs. -

Regional Market Dynamics

Asia-Pacific is projected to dominate the market due to rapid industrialization and construction activities in China, India, and Southeast Asia. North America and Europe will see moderate growth, supported by infrastructure renewal projects and strict safety regulations. Latin America and the Middle East present emerging opportunities due to rising industrial investments. -

Technological Integration and Customization

Digital manufacturing technologies such as CNC weaving and laser cutting are enabling precise customization of mesh specifications. Customers increasingly demand tailored solutions, including specific tensile strength, coating types, and roll sizes, driving innovation in production capabilities. -

Supply Chain Resilience and Local Sourcing

Post-pandemic supply chain disruptions have prompted companies to localize production and diversify sourcing. This trend is expected to continue, with more manufacturers establishing regional production hubs to reduce lead times and mitigate geopolitical risks.

In summary, the 1/8 inch wire mesh market in 2026 will be characterized by technological advancement, material innovation, and broad-based demand across multiple sectors. Companies that prioritize sustainability, customization, and supply chain agility are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing 1/8 Inch Wire Mesh (Quality & IP Considerations)

Sourcing 1/8 inch wire mesh may seem straightforward, but overlooking key quality and IP (Ingress Protection) factors can lead to product failure, safety hazards, and increased costs. Here are critical pitfalls to avoid:

Inadequate Material Specification and Verification

One of the most frequent mistakes is failing to clearly define and verify the base material. Assuming “wire mesh” implies a specific alloy (like 304 or 316 stainless steel) without explicit confirmation can result in receiving inferior materials such as low-grade carbon steel or non-stainless alloys. This compromises corrosion resistance, strength, and longevity, especially in harsh environments. Always demand mill test certificates (MTCs) to validate material composition and ensure it meets required standards (e.g., ASTM A409 for stainless steel).

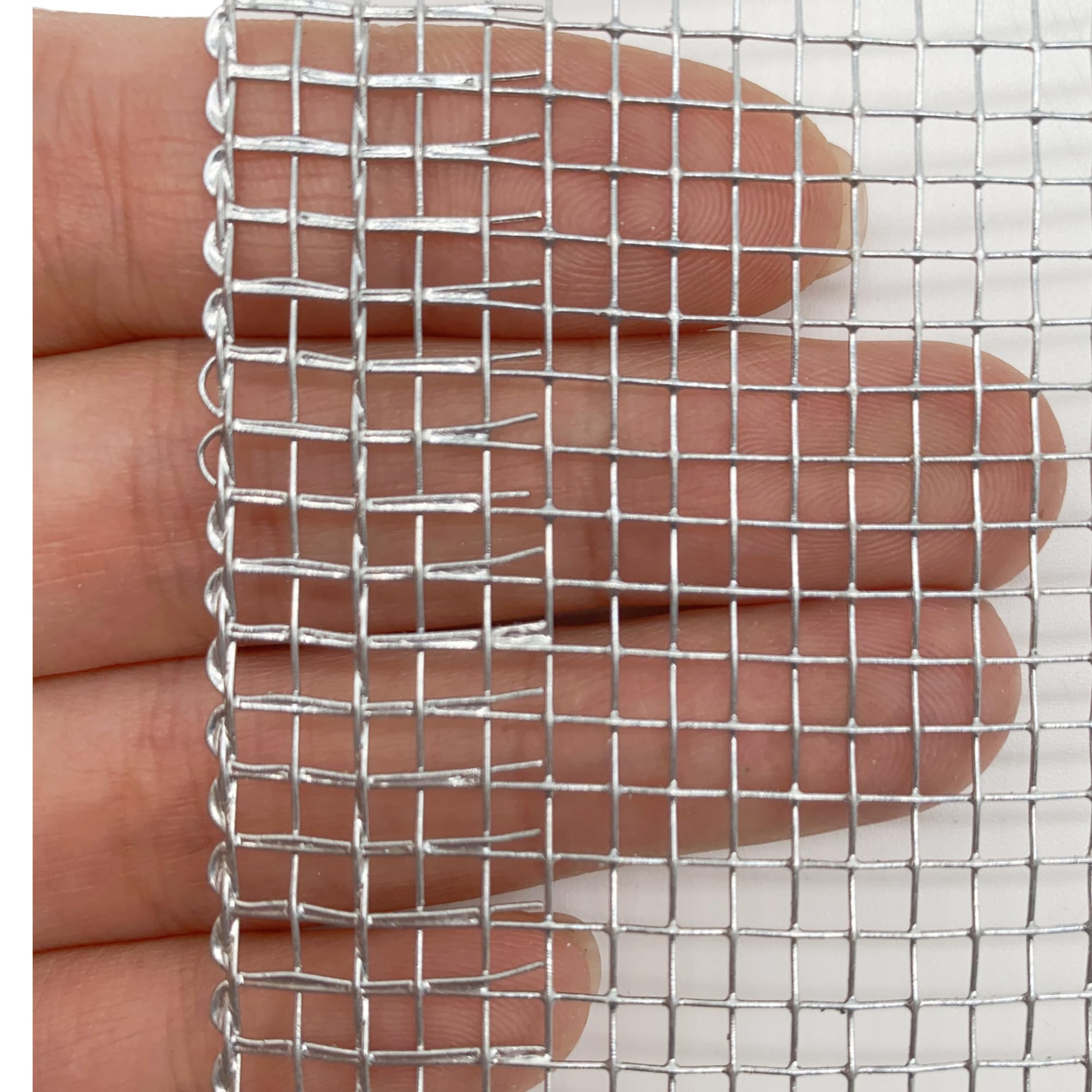

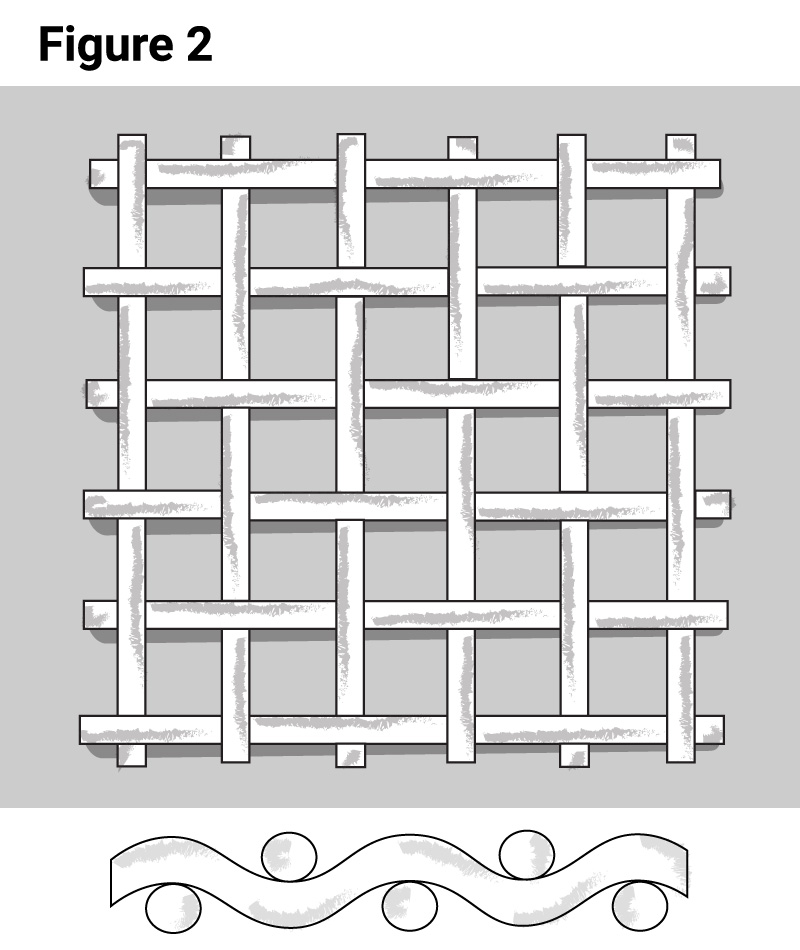

Overlooking Weave Type and Tolerance Consistency

The performance of 1/8 inch wire mesh heavily depends on its weave pattern (e.g., plain weave, twill weave) and dimensional tolerances. Sourcing without specifying acceptable tolerances for wire diameter, opening size, and overall flatness can result in inconsistent mesh that doesn’t fit properly or perform as expected. For example, a mesh with oversized openings may fail to filter particulates effectively, while uneven tension can cause warping during installation.

Ignoring Surface Finish and Cleanliness

For applications requiring hygiene or corrosion resistance (e.g., food processing, pharmaceuticals), surface finish is critical. A rough or contaminated surface can harbor bacteria or accelerate corrosion. Suppliers may deliver mesh with mill scale, oil residue, or burrs if surface finish requirements (e.g., electropolished, passivated) aren’t explicitly stated. Always include surface quality specifications and conduct incoming inspections.

Misunderstanding IP Rating Requirements

Many assume that any 1/8 inch mesh automatically provides a specific IP rating (e.g., IP54 for dust and water splashes). However, IP ratings depend on the entire enclosure design, including frame sealing and mesh attachment—not just the mesh itself. Relying solely on mesh size without engineering the full system can result in inadequate protection. Work with suppliers who understand IP standards and can advise on system-level performance.

Failing to Assess Weld or Join Integrity

For welded wire mesh, the strength and consistency of weld points are crucial. Poorly fused or inconsistently spaced welds create weak spots that can lead to structural failure. Visual inspection alone is insufficient—ask for quality control reports and, when critical, perform destructive testing on sample batches to verify weld integrity.

Neglecting Regulatory and Industry Compliance

Depending on the application, wire mesh may need to comply with industry-specific regulations (e.g., FDA for food contact, UL for electrical enclosures). Sourcing without confirming compliance documentation can lead to rejected shipments or non-compliant end products. Always verify that the mesh meets relevant industry standards and certifications.

Choosing Solely on Price Without Total Cost Analysis

Opting for the cheapest supplier often leads to hidden costs from rework, premature failure, or downtime. Low-cost mesh may use substandard materials or lack quality controls. Evaluate suppliers based on total value, including reliability, consistency, technical support, and after-sales service—not just initial price.

Avoiding these pitfalls requires clear specifications, thorough supplier vetting, and proactive quality checks. Investing time upfront ensures the 1/8 inch wire mesh performs reliably in its intended application.

Logistics & Compliance Guide for 1/8″ Wire Mesh

Product Overview

1/8″ wire mesh, also known as 0.125-inch wire mesh or 3.175 mm wire mesh, is a woven or welded metal grid commonly used in industrial, construction, filtration, and agricultural applications. It typically comes in various materials such as stainless steel, galvanized steel, or aluminum, with specific mesh counts (e.g., 20×20, 24×24) determining aperture size and strength.

Classification & HS Code

Proper classification is essential for international shipping and customs compliance.

-

HS Code Example: 7314.31.00 (Woven wire cloth, grill, or net, of iron or steel, not coated or plated)

Note: Final HS code depends on material, weave type, coating, and country of destination. Always verify with local customs authorities. -

Material-Specific Codes:

- Stainless Steel: 7314.42.00

- Galvanized Steel: 7314.39.00

- Aluminum: 7616.99.51

Ensure accurate classification to avoid customs delays or penalties.

Packaging & Handling Requirements

Proper packaging ensures the product arrives undamaged and complies with transport regulations.

- Rolls: Typically packaged in waterproof plastic wrap, cardboard cores, and secured on wooden pallets.

- Sheets: Bundled securely with steel or plastic strapping, edge-protected to prevent damage.

- Labeling: Include product specifications (mesh size, material, dimensions), handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”), and compliance markings.

- Weight & Dimensions: Standard roll sizes vary (e.g., 36″ x 100′), but must be declared accurately for freight calculations.

Transportation & Freight Considerations

Choose the appropriate shipping method based on order size, urgency, and destination.

- Domestic Shipping: LTL (Less Than Truckload) or FTL (Full Truckload) for bulk orders.

- International Shipping: Ocean freight (FCL/LCL) recommended for large volumes; air freight for urgent, small shipments.

- Stackability: Wire mesh rolls can be stacked if palletized correctly, but avoid excessive pressure to prevent deformation.

- Environmental Protection: Protect from moisture, especially galvanized or carbon steel mesh, to prevent rust during transit.

Import/Export Documentation

Accurate documentation ensures smooth customs clearance.

- Commercial Invoice: Must include product description, quantity, value, country of origin, and HS code.

- Packing List: Detail contents per package, weight, dimensions, and packaging type.

- Bill of Lading (B/L): Required for ocean freight; Air Waybill (AWB) for air shipments.

- Certificate of Origin: May be required for preferential tariff treatment (e.g., under USMCA, EU agreements).

- Material Certification: Provide mill test reports (e.g., MTR) when requested, especially for stainless steel mesh in regulated industries.

Regulatory Compliance

Adhere to international and local regulations based on destination and end-use.

- REACH & RoHS (EU): Ensure no restricted substances are present, particularly in stainless steel alloys.

- FDA Compliance: Required if used in food processing or pharmaceutical filtration applications.

- OSHA & ANSI (USA): Relevant for safety applications (e.g., machine guards), verify load and strength ratings.

- Country-Specific Standards: Some markets require local certifications (e.g., CCC in China, BIS in India).

Storage Guidelines

Proper storage maintains product integrity before and after delivery.

- Environment: Store indoors in a dry, well-ventilated area to prevent corrosion.

- Pallet Support: Keep on flat, level surfaces; avoid uneven ground or damp floors.

- Segregation: Separate different materials (e.g., stainless vs. galvanized) to avoid galvanic corrosion.

- Shelf Life: Indefinite if stored properly; inspect periodically for signs of moisture damage.

Returns & Non-Conformance

Establish clear procedures for quality issues or logistics errors.

- Damage in Transit: Document with photos and file a claim with the carrier immediately.

- Non-Compliant Shipments: Return only with prior authorization; include reason (e.g., wrong mesh count, damaged packaging).

- Restocking Fees: May apply if return is not due to supplier error.

Environmental & Safety Considerations

Handle with care due to sharp edges and weight.

- PPE Required: Gloves and safety glasses recommended during handling.

- Recycling: Wire mesh is 100% recyclable; encourage proper disposal or return programs.

- Hazardous Materials: Generally not classified as hazardous, but sharp edges require safe handling protocols.

Summary

Shipping and managing 1/8″ wire mesh requires attention to material specifications, accurate classification, proper packaging, and compliance with international trade regulations. By following this guide, logistics teams can ensure timely delivery, reduce risk, and maintain quality standards across the supply chain. Always consult with customs brokers and freight forwarders to stay updated on regulatory changes.

Conclusion for Sourcing 1/8-inch Wire Mesh:

After evaluating various suppliers, material options, and cost considerations, sourcing 1/8-inch wire mesh requires a balanced approach that prioritizes quality, durability, and cost-effectiveness. Galvanized steel is the most commonly recommended material due to its corrosion resistance and strength, making it suitable for applications in construction, filtration, or agricultural settings. Stainless steel may be preferred for environments requiring higher resistance to rust and chemicals, despite the higher initial cost.

Key factors in successful sourcing include verifying mesh specifications (such as aperture size, wire diameter, and weave pattern), ensuring compliance with industry standards (e.g., ASTM or ISO), and selecting reliable suppliers with consistent product quality and on-time delivery. Bulk purchasing can yield cost savings, but it should be balanced with storage capacity and lead time requirements.

In summary, sourcing 1/8-inch wire mesh effectively involves selecting the appropriate material and weave type for the intended application, partnering with reputable suppliers, and conducting ongoing quality checks to ensure long-term performance and value.