The global automotive and industrial connector market has seen robust growth, driven by increasing demand for reliable electrical connections in harsh environments. According to a report by Mordor Intelligence, the global automotive connectors market was valued at USD 20.3 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. A key contributor to this trend is the rising adoption of Deutsch connectors—known for their durability, resistance to vibration, and performance in extreme conditions—especially within commercial vehicles, off-road machinery, and defense applications. Among these, 12-pin Deutsch connectors are among the most widely used configurations due to their optimal balance of signal capacity and compact design. As demand surges, several manufacturers have emerged as leaders in engineering precision, scalability, and compliance with international standards. Based on market presence, production volume, innovation, and global distribution, the following are the top seven manufacturers of 12-pin Deutsch connectors shaping the industry landscape.

Top 7 12 Pin Deutsch Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

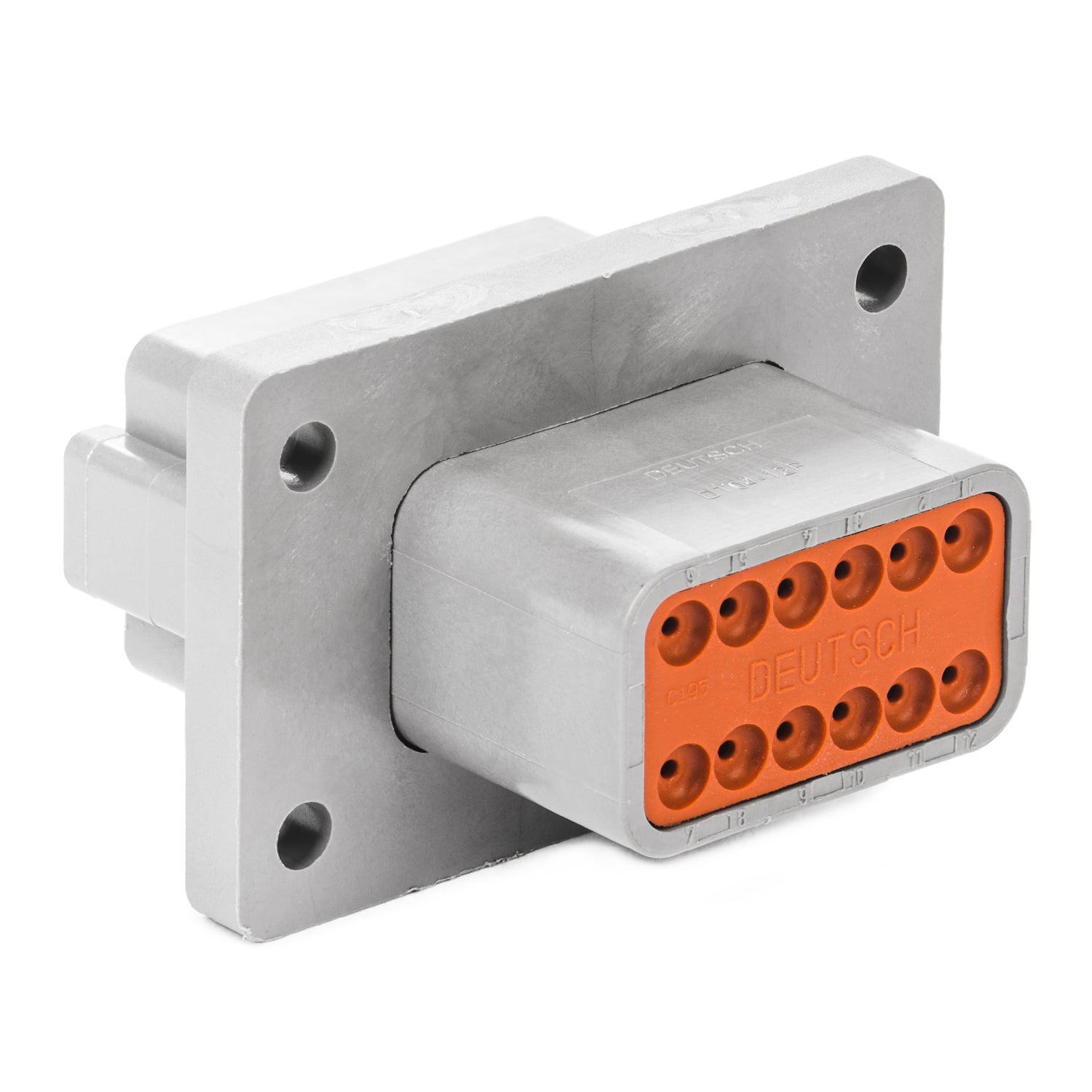

#1 Deutsch Connectors

Website: universalconnectors.com

Key Highlights: Explore Deutsch Connectors’ official site – waterproof, temp-resistant options. Custom-fit, durable builds for auto/industrial needs; reliable connections, ……

#2 DEUTSCH Connectors, Pins, Sockets, and Plugs

Domain Est. 1992

Website: te.com

Key Highlights: Our portfolio offers a wide assortment of design options, including 4 pin connectors, 6 pin connectors, 8 pin connectors, and 12 pin connectors, among others….

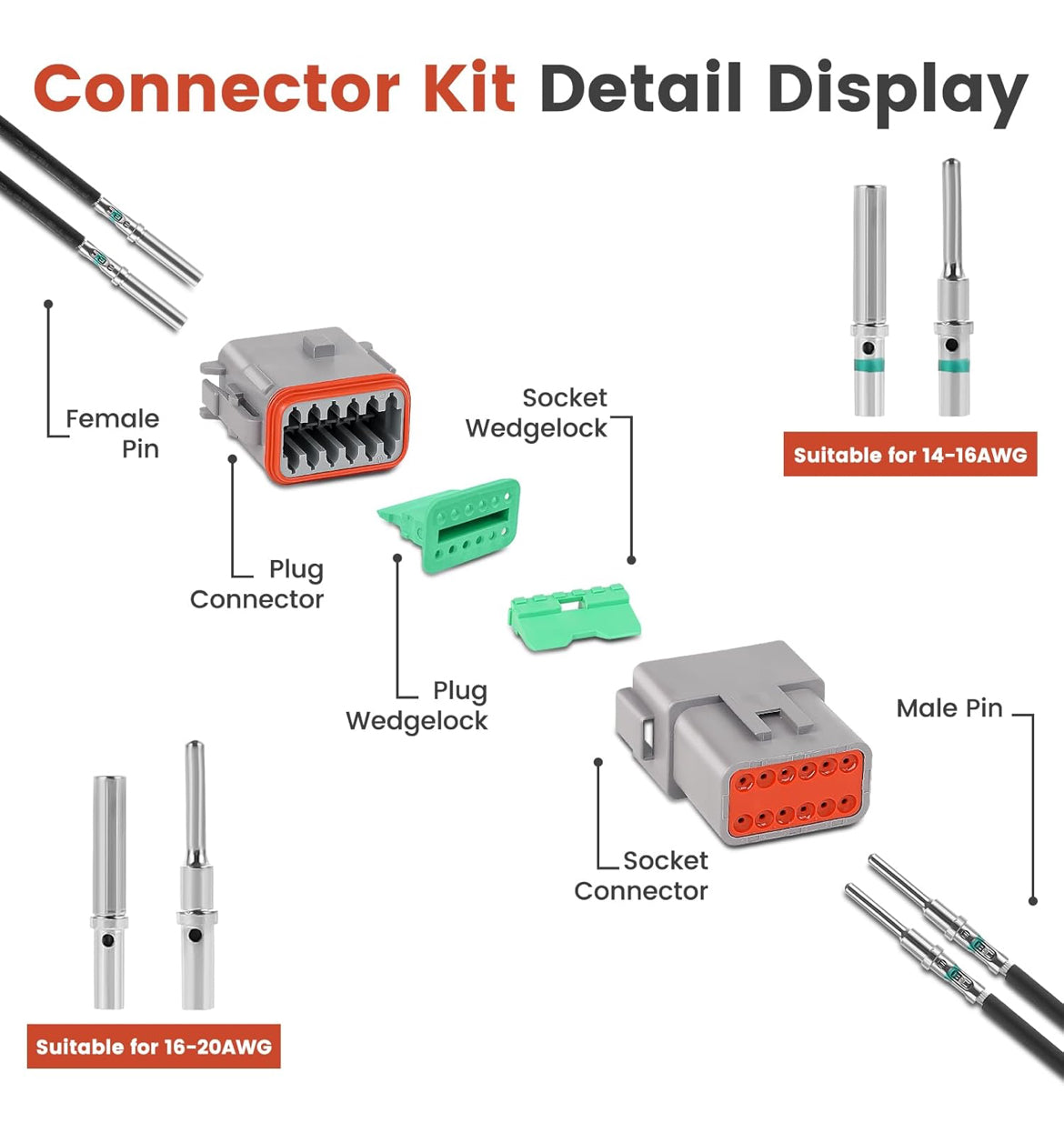

#3 Deutsch 12 Pin (Male & Female) Connector Kit

Domain Est. 2000

Website: wirecare.com

Key Highlights: In stock Rating 3.8 5 This Deutsch 12 pin kit contains all of the items necessary to complete both ends of a 12 contact assembly using a genuine Deutsch DT series connectors….

#4 DeutschConnector.com

Domain Est. 2004

Website: deutschconnector.com

Key Highlights: DeutschConnector.com offers a comprehensive selection of Deutsch connectors, tools, accessories and replacement parts as well as technical support….

#5 DT06-12SA

Domain Est. 2012

Website: deutschconnectorstore.com

Key Highlights: Compatible with stamped and solid barrel, size 16, socket (female) contacts. This connector housing requires a wedgelock, contacts, and a mating connector….

#6 DEUTSCH Professional Connector Assembly Sets

Domain Est. 2016

Website: customconnectorkits.com

Key Highlights: Free delivery over $124.99DEUTSCH Connector Kits at Custom Connector Kits. Find high-quality assembly sets for your electrical needs. Shop now!…

#7 12 Pin Stamped and Formed Contact Connector Kit DT12GY

Domain Est. 2018

Expert Sourcing Insights for 12 Pin Deutsch Connector

H2: 2026 Market Trends for 12 Pin Deutsch Connector

The global market for 12 Pin Deutsch connectors is poised for robust growth through 2026, driven by increasing demand across key industrial and automotive sectors. These high-performance connectors, known for their durability, resistance to harsh environments, and reliable signal transmission, are critical components in heavy-duty applications.

One of the primary drivers shaping the 2026 market landscape is the continued expansion of the off-highway and commercial vehicle industries. Equipment used in construction, agriculture, and mining increasingly relies on advanced electronic control systems—many of which depend on 12 Pin Deutsch connectors for stable electrical connections. As automation and telematics become more prevalent in such machinery, the need for rugged and secure connectors will intensify.

Additionally, the global push toward electrification and hybrid technologies in transportation is influencing demand. While full electric vehicles often utilize different connector standards, hybrid and transitional powertrain systems still incorporate Deutsch connectors for sensors, auxiliary systems, and legacy compatibility. This transitional phase is expected to sustain demand through 2026, particularly in emerging markets where diesel and hybrid systems remain dominant.

Another significant trend is the growing emphasis on supply chain localization and resilience. In response to recent global disruptions, manufacturers in North America and Europe are reevaluating sourcing strategies. This shift is likely to benefit regional producers of Deutsch connectors, supporting market growth and innovation in materials and miniaturization.

Technological advancements are also shaping product development. By 2026, we anticipate increased integration of smart diagnostics and enhanced sealing technologies within 12 Pin Deutsch connectors. These upgrades will allow for predictive maintenance and improved performance in extreme conditions, appealing to industries such as oil and gas, defense, and renewable energy.

Finally, sustainability concerns are prompting connector manufacturers to explore recyclable materials and energy-efficient production processes. While the core value of Deutsch connectors lies in longevity and reliability, environmental compliance will become a differentiating factor in competitive bidding and procurement decisions.

In summary, the 2026 market for 12 Pin Deutsch connectors will be characterized by steady growth, technological enhancement, and sector-specific demand driven by industrial automation, vehicle electrification trends, and supply chain localization efforts.

Common Pitfalls When Sourcing 12-Pin Deutsch Connectors (Quality and IP Ratings)

Sourcing 12-pin Deutsch connectors—commonly used in harsh environments like automotive, industrial, and aerospace applications—can be challenging if not approached carefully. While these connectors are known for durability and reliability, several pitfalls related to quality and Ingress Protection (IP) ratings can compromise performance if overlooked.

1. Assuming All Deutsch-Style Connectors Are Genuine

A major pitfall is assuming that connectors labeled “Deutsch-style” meet genuine Deutsch (TE Connectivity) specifications. Many low-cost alternatives mimic the design but fail to deliver the same performance. Counterfeit or non-certified connectors may use inferior materials, leading to poor contact resistance, reduced mating cycles, or premature failure.

Solution: Source from authorized distributors or directly from TE Connectivity. Verify part numbers and look for authentication marks or datasheets.

2. Overlooking IP Rating Compliance

The IP rating (e.g., IP67, IP69K) defines protection against dust and water ingress. Many suppliers claim high IP ratings, but not all connectors are tested or certified to meet those standards.

Pitfall: Purchasing connectors that claim “IP67 equivalent” without third-party certification may result in moisture ingress, short circuits, or corrosion in demanding environments.

Solution: Require test reports or certification (e.g., UL, IEC) proving the connector meets the stated IP rating under real-world conditions.

3. Inconsistent Quality from Low-Cost Suppliers

Sourcing from low-cost manufacturers—especially in regions with lax quality control—may result in inconsistent molding, poor terminal crimping, or substandard seals.

Pitfall: Batch-to-batch variation can lead to field failures, increased warranty claims, and downtime.

Solution: Conduct supplier audits, request samples for testing, and implement incoming quality inspections.

4. Mismatched Terminal and Housing Quality

Even if the connector housing appears robust, low-quality or incompatible terminals can undermine performance. Poor plating (e.g., insufficient tin or gold thickness) increases resistance and risk of corrosion.

Pitfall: Using generic or incompatible terminals can cause overheating, intermittent connections, or arcing.

Solution: Use only OEM-recommended terminals and tooling. Verify compatibility with the housing and mating plug.

5. Inadequate Strain Relief and Cable Glands

Some 12-pin Deutsch connectors rely on backshells or cable glands for strain relief and sealing. Low-quality or missing components compromise both mechanical durability and IP rating.

Pitfall: Without proper strain relief, vibration or movement can damage wire terminations or breach the seal.

Solution: Ensure the full assembly—connector, backshell, grommet, and gland—meets environmental and mechanical requirements.

6. Lack of Temperature and Chemical Resistance Verification

Deutsch connectors are often used in high-temperature or chemically aggressive environments. Not all materials (e.g., thermoplastic housings or seal elastomers) perform equally under such conditions.

Pitfall: Connectors that degrade under heat or exposure to oils, fuels, or cleaning agents can fail prematurely.

Solution: Confirm material specifications (e.g., UL 94 flammability rating, operating temperature range) match application demands.

7. Ignoring Assembly and Tooling Requirements

Proper crimping and insertion tools are essential for reliable connections. Using incorrect or poorly maintained tools leads to poor terminal engagement or damaged seals.

Pitfall: Field failures due to improperly seated contacts or damaged O-rings.

Solution: Invest in OEM-recommended tooling and train personnel in proper assembly procedures.

By being aware of these common pitfalls and taking proactive steps—such as verifying authenticity, demanding certification, and using compatible components—you can ensure reliable performance of 12-pin Deutsch connectors in critical applications.

Logistics & Compliance Guide for 12 Pin Deutsch Connector

Overview

The 12 Pin Deutsch Connector is a heavy-duty electrical connector commonly used in harsh environments across industries such as automotive, off-highway vehicles, agriculture, and industrial machinery. Ensuring proper logistics handling and regulatory compliance is essential for safe, reliable, and legal distribution and use.

Packaging & Handling

- Protective Packaging: Always use anti-static and moisture-resistant packaging to protect connectors from environmental damage.

- Labeling: Clearly label packages with part number (e.g., DTM06-12P), manufacturer (TE Connectivity/Deutsch), quantity, and handling symbols (e.g., “Fragile,” “Do Not Crush”).

- Storage Conditions: Store in a dry, temperature-controlled environment (typically 15°C to 35°C). Avoid exposure to UV light, chemicals, and dust.

- Handling Precautions: Avoid dropping or mechanically stressing connectors. Use ESD-safe practices when handling to prevent damage to internal components.

Transportation Requirements

- Domestic (U.S.): Comply with Department of Transportation (DOT) regulations if shipping hazardous materials (rare for connectors unless combined with flammable packaging). Standard ground or air freight acceptable.

- International Shipping:

- Use IATA-compliant packaging for air freight.

- Follow IMDG Code for sea transport if applicable.

- Include commercial invoice, packing list, and bill of lading.

- Customs Documentation: Provide Harmonized System (HS) Code – typically 8536.90 (electrical connectors). Confirm exact code with customs broker.

- Restricted Materials: Verify connectors are free of substances restricted under RoHS, REACH, or Prop 65.

Regulatory Compliance

- RoHS (EU): Ensure connectors comply with Directive 2011/65/EU on restriction of hazardous substances (e.g., lead, cadmium, mercury). Deutsch connectors are typically RoHS-compliant; verify with manufacturer’s Declaration of Conformity (DoC).

- REACH (EU): Confirm compliance with SVHC (Substances of Very High Concern). Request REACH compliance statement from supplier.

- UL/CSA Certification: For use in North America, ensure connectors meet UL 486A-486B and CSA 22.2 standards for wire connectors. Most Deutsch connectors are UL recognized.

- IP Rating: Confirm ingress protection rating (commonly IP67 or IP69K) for use in outdoor or washdown environments. Document and communicate this to end users.

Export Controls

- EAR99 Classification: Most 12 Pin Deutsch Connectors are classified as EAR99 under the U.S. Export Administration Regulations, meaning they are low-risk and generally do not require an export license.

- Restricted Destinations: Screen end-users and destinations against U.S. and EU sanctions lists (e.g., OFAC, EU Consolidated List). Avoid shipping to embargoed countries without proper authorization.

Documentation & Traceability

- Certificate of Conformance (CoC): Require CoC from manufacturer or distributor confirming compliance with applicable standards.

- Lot Traceability: Maintain batch/lot numbers and supplier records to support quality audits and recalls.

- Conflict Minerals: If required, confirm whether the product contains tin, tantalum, tungsten, or gold (3TG) and submit necessary reporting (e.g., SEC Form SD).

Returns & Reverse Logistics

- Defective Units: Follow manufacturer’s return material authorization (RMA) process. Clearly label returned goods with reason for return.

- Environmental Disposal: Recycle or dispose of non-functional connectors per local e-waste regulations (e.g., WEEE in EU).

Best Practices Summary

- Verify compliance documentation before procurement.

- Train logistics staff on ESD and environmental handling.

- Audit suppliers regularly for ongoing compliance.

- Keep digital records of all certifications and shipping documents for at least 5 years.

For specific applications (e.g., military, aerospace), additional standards such as MIL-DTL-38999 or AS9100 may apply—consult technical specifications accordingly.

Conclusion for Sourcing 12-Pin Deutsch Connector:

After evaluating suppliers, technical specifications, cost, quality, and availability, sourcing a 12-pin Deutsch connector (such as the DTM or DTP series) should prioritize OEM authenticity or certified aftermarket alternatives to ensure reliability, environmental resistance, and long-term compatibility. Given the importance of durability in harsh environments—such as industrial, automotive, or agricultural applications—it is recommended to source connectors from authorized distributors or directly from Deutsch (TE Connectivity) to guarantee performance and avoid counterfeit products.

Cost-effective alternatives may be available from reputable third-party manufacturers, provided they meet applicable standards (e.g., IP67/IP69K, MIL-DTL-22520 compliance). However, careful validation of specifications—including pin configuration, gender, shell size, and sealing—is essential to ensure proper fit and function.

In conclusion, a balanced approach that emphasizes quality assurance, technical compatibility, and supply chain reliability will ensure optimal performance and minimize downtime when integrating 12-pin Deutsch connectors into your system.