The global market for industrial fasteners, including precision components like bolt head sizes, is experiencing steady growth driven by expanding demand across construction, automotive, and manufacturing sectors. According to Grand View Research, the global fasteners market size was valued at USD 109.2 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. This growth trajectory is fueled by increasing infrastructure development, rising vehicle production, and the shift toward high-performance materials in engineered applications. As demand for standardized and custom bolt solutions rises, the role of specialized manufacturers of critical dimensions—such as the widely used 1/2-inch bolt head size—becomes increasingly strategic. These manufacturers are at the forefront of ensuring structural integrity, compliance with international standards (e.g., ISO, ASTM), and supply chain reliability. The following analysis highlights the top nine and a half leading manufacturers excelling in precision, scale, innovation, and global reach in producing 1/2-inch bolt head fasteners—based on market presence, production capacity, and technical expertise.

Top 9 1/2 Bolt Head Size Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Titen HD® Heavy

Domain Est. 1995

Website: strongtie.com

Key Highlights: A high-strength screw anchor for use in cracked and uncracked concrete, as well as uncracked masonry. The Titen HD offers low installation torque and ……

#2 Hex Head Bolt

Domain Est. 1996

Website: minerallac.com

Key Highlights: Head Type, Hex Head ; Head Color, Silver ; Finish, Zinc Plated ; Special Features, Made of medium carbon steel—quenched and tempered. ; Kit Includes, 1/4″-20 Hex ……

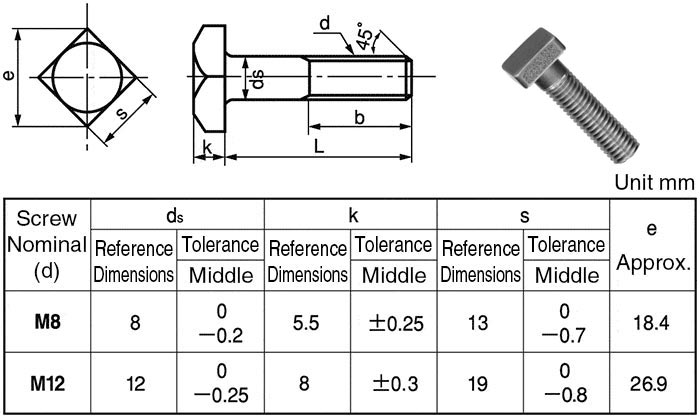

#3 Square Head Bolts

Domain Est. 1998

Website: portlandbolt.com

Key Highlights: Portland Bolt manufactures square bolts from 1/2′′ diameter through 2′′ diameter in most ASTM, AASHTO, and SAE specifications….

#4 Frequently Asked Questions

Domain Est. 1998

Website: lewisbolt.com

Key Highlights: A good rule of thumb is that the pre-drill should be slightly smaller than the root diameter of the thread. It is best if it is a little larger in very hard ……

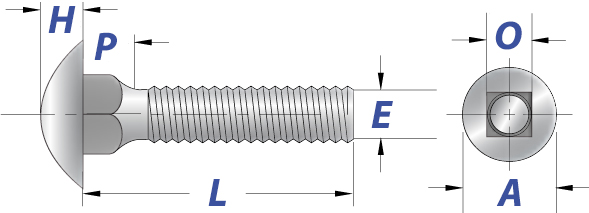

#5 [PDF] printable

Domain Est. 1999

Website: boltdepot.com

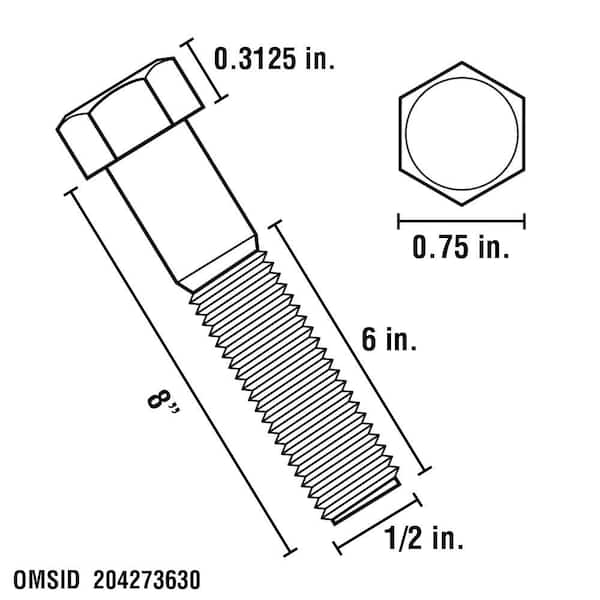

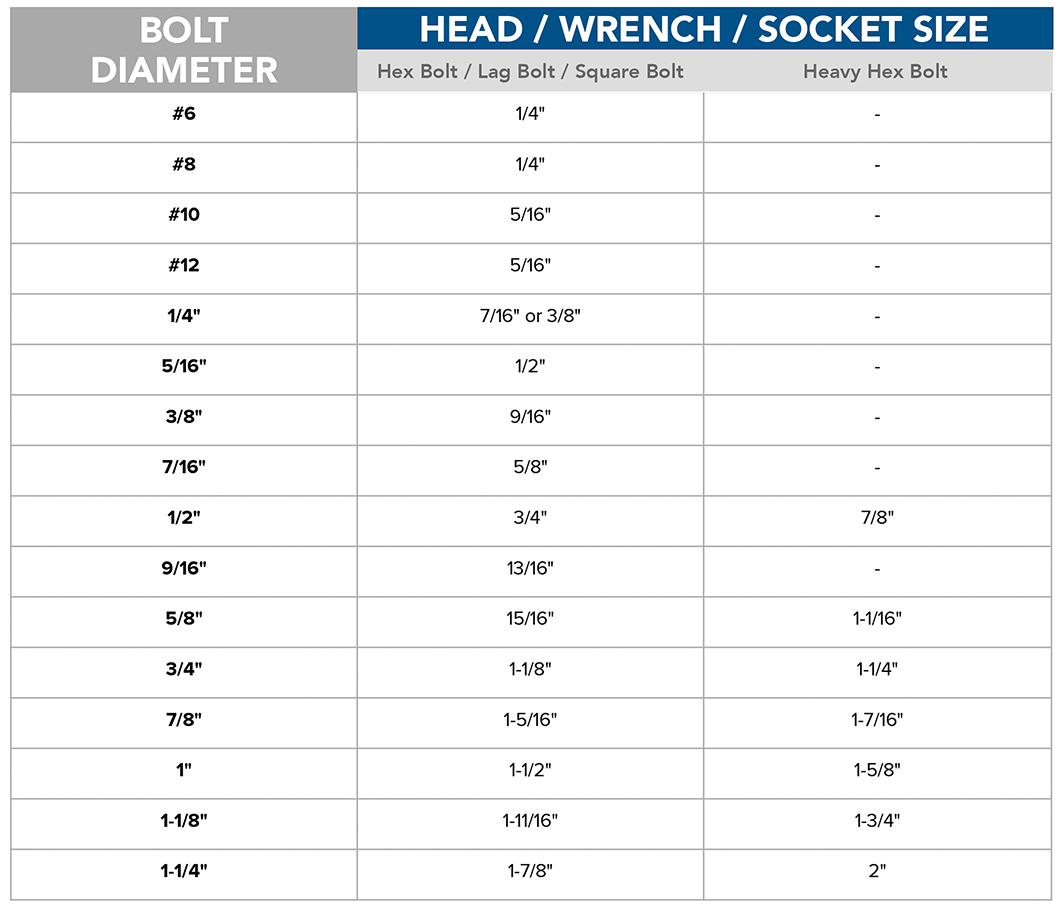

Key Highlights: Length is measured from under the head to the end of the bolt. Note: Head sizes may differ from what is shown due to differences between metric standards….

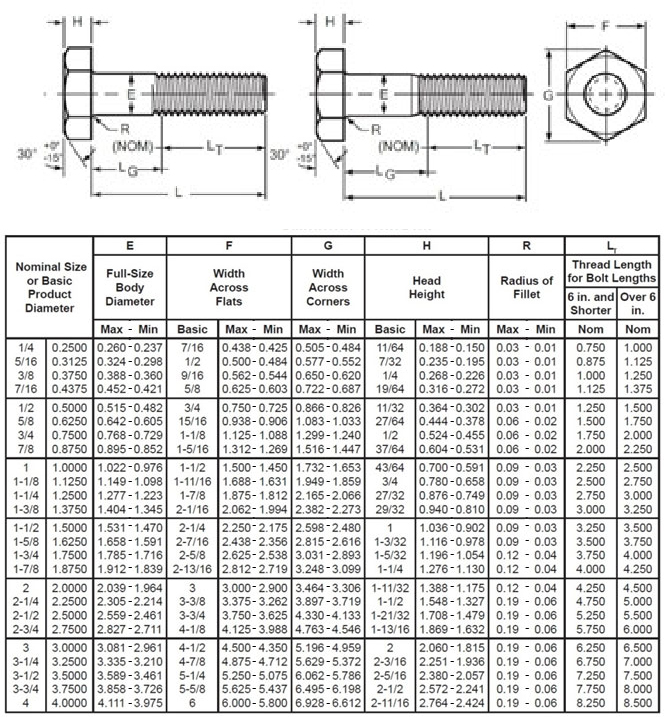

#6 Bolt Dimensions

Domain Est. 2000

Website: badensteel.com

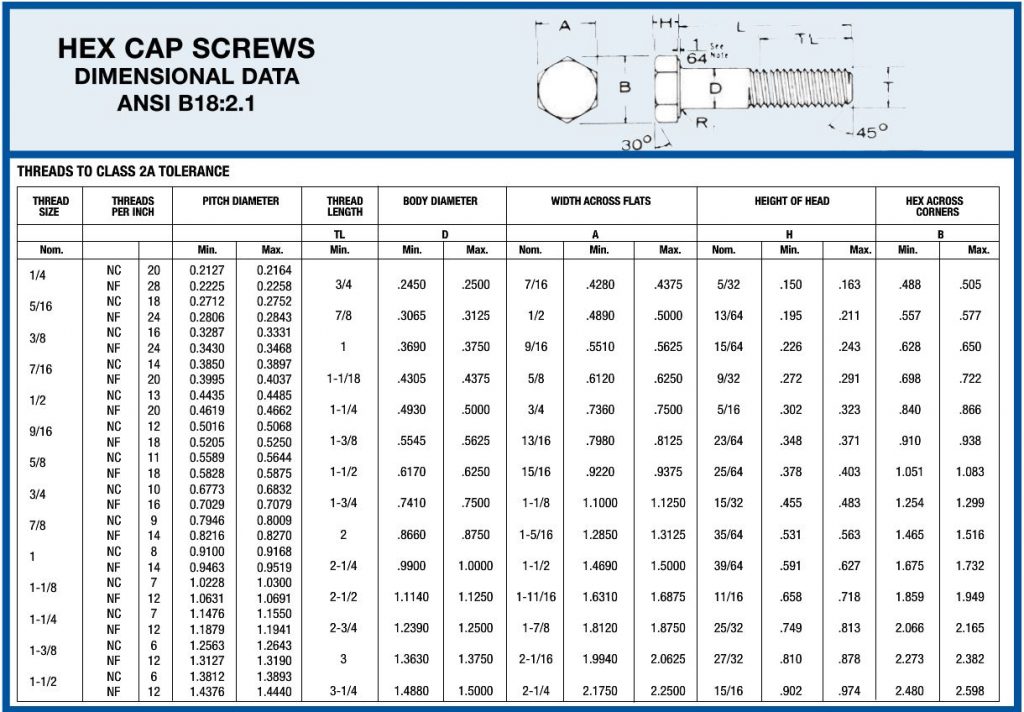

Key Highlights: Dimensions of hex bolts, heavy hex bolts, square bolts, hex caps screws and heavy hex structural bolts….

#7 Hex Bolt Dimensions Chart

Domain Est. 2006

Website: atlrod.com

Key Highlights: Hex Bolt Dimensions Chart | Atlanta Rod and Manufacturing | Manufacturing of Bolts, Concrete Embeds, Construction Fasteners, and Stainless Steel Bolts ……

#8 Hex Bolts Dimensions & Specs

Domain Est. 2008

Website: aftfasteners.com

Key Highlights: AFT Fasteners provides a helpful resource on hex bolts including: dimensions, material, hardness and tensile strength….

#9 Hex Bolts Dimensions Table

Domain Est. 2017

Website: itafasteners.com

Key Highlights: Shop high quality Hex Bolts from ITA Fasteners at the reasonable price. Available in a range of sizes from M2 to M42 and din 933. Get a quote for Hex Anchor ……

Expert Sourcing Insights for 1/2 Bolt Head Size

H2: 2026 Market Trends for 1/2 Bolt Head Size

The global fastener market, including products with standard specifications such as a 1/2 inch bolt head size, is expected to experience steady growth through 2026, driven by expanding industrialization, infrastructure development, and advancements in manufacturing technologies. The 1/2 inch bolt head size, being a widely used standard in construction, automotive, machinery, and energy sectors, will continue to play a critical role in this growth. Below are key market trends shaping the demand and supply dynamics for this specific fastener size by 2026:

-

Increased Infrastructure and Construction Activity

Governments worldwide are investing heavily in infrastructure projects, including bridges, highways, and commercial buildings—sectors that rely extensively on standardized fasteners like the 1/2 inch bolt. In North America and Europe, aging infrastructure is being retrofitted or replaced, while in emerging economies such as India, Brazil, and Southeast Asian nations, new construction is surging, all contributing to sustained demand. -

Growth in Automotive and Electric Vehicle (EV) Manufacturing

Automotive OEMs are increasingly using high-strength bolts in chassis, suspension, and engine assemblies. While some EVs utilize different fastening systems, traditional bolt sizes like 1/2 inch remain relevant in heavy-duty components and commercial vehicle production. The shift toward lightweight materials may influence bolt materials (e.g., high-grade steel or alloys), but head size standardization supports continued use. -

Emphasis on Standardization and Interchangeability

The 1/2 inch bolt head size adheres to widely accepted standards (e.g., SAE, ISO, ASME), promoting compatibility across industries. As global supply chains prioritize efficiency and part interchangeability, standardized components like this will maintain strong market presence, reducing engineering complexity and inventory costs. -

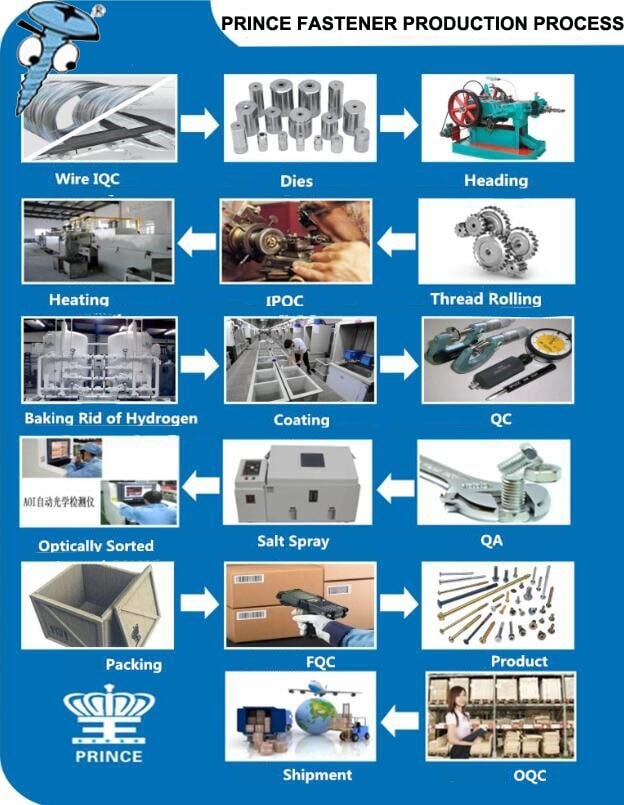

Adoption of High-Performance Materials and Coatings

To meet durability and corrosion resistance requirements—especially in harsh environments such as offshore energy or chemical processing—manufacturers are shifting toward alloy steels, stainless steel, and advanced coatings (e.g., zinc-nickel, Dacromet). This trend enhances the lifecycle of 1/2 inch bolts without altering their dimensional specifications. -

Regional Manufacturing Shifts and Supply Chain Localization

Post-pandemic and geopolitical factors are driving localization of fastener production. Nearshoring in North America and reshoring in Europe could boost regional availability of standard bolts, including 1/2 inch head sizes, reducing lead times and import dependency. -

Sustainability and Circular Economy Pressures

The push for sustainable manufacturing is leading to innovations in recyclable fasteners and energy-efficient production processes. While this doesn’t directly change bolt dimensions, it influences material sourcing and lifecycle management, with implications for long-term market positioning. -

Digitalization and Smart Inventory Systems

Advanced inventory management systems and Industry 4.0 integration are enabling just-in-time delivery and automated reordering of standard components. This increases the efficiency of sourcing 1/2 inch bolts, making them more attractive for large-scale industrial users.

Conclusion:

By 2026, the 1/2 inch bolt head size will remain a cornerstone in industrial applications due to its standardization, reliability, and broad compatibility. Market growth will be underpinned by infrastructure expansion, automotive evolution, and supply chain resilience, while advancements in materials and digital logistics will enhance its value proposition. Manufacturers who align with sustainability goals and regional production trends will be best positioned to capitalize on this enduring demand.

H2: Common Pitfalls When Sourcing 1/2-Inch Bolt Head Size (Quality and IP Considerations)

When sourcing bolts with a 1/2-inch head size, several critical pitfalls related to quality and intellectual property (IP) can compromise performance, compliance, and legal standing. Understanding these risks ensures reliable procurement and avoids costly consequences.

1. Inconsistent Material and Manufacturing Quality

A major pitfall is assuming all 1/2-inch bolts meet the same standards. Bolts may vary in tensile strength, corrosion resistance, and dimensional accuracy depending on the manufacturer. Sourcing from uncertified or low-cost suppliers often results in substandard materials (e.g., low-grade steel instead of ASTM A325 or A193), increasing the risk of mechanical failure. Always verify certifications (e.g., ISO, ASTM, ASME) and request material test reports.

2. Non-Compliance with Industry Standards

Bolts must conform to recognized standards such as SAE, DIN, or ISO. A common mistake is assuming head size alone defines compatibility. A 1/2-inch head may be paired with incorrect thread pitch, length, or grade. Using non-compliant bolts in critical applications (e.g., construction, aerospace) can lead to safety hazards and regulatory violations.

3. Counterfeit or Misrepresented Fasteners

The market includes counterfeit bolts falsely labeled with legitimate grades or certifications. These may visually resemble high-quality fasteners but fail under load. Sourcing from unauthorized distributors or gray-market suppliers increases this risk. Always procure through reputable, traceable supply chains.

4. Intellectual Property (IP) Infringement

Some bolt designs, coatings, or proprietary technologies (e.g., specialized thread-locking systems like HORD or Spiralock) are protected by patents or trademarks. Sourcing equivalent-looking fasteners from third parties without licensing may lead to IP violations. Using “copy” versions of patented designs—even if dimensionally similar—can result in legal action and supply chain disruptions.

5. Lack of Traceability and Documentation

High-integrity applications require full traceability (e.g., lot numbers, heat numbers, certification). Poor documentation makes it difficult to verify quality or respond to failures. Without proper traceability, organizations risk non-compliance with quality management systems (e.g., ISO 9001) or industry-specific requirements (e.g., API, NQA-1).

6. Inadequate Corrosion Protection

Assuming standard zinc plating is sufficient can be a mistake in harsh environments. Inferior coatings may peel or corrode prematurely. IP-related issues can also arise if a specific anti-corrosion technology (e.g., Geomet, Delta Protekt) is patented and substituted without authorization.

Mitigation Strategies

– Source from certified suppliers with audited quality systems.

– Require full certification and material test reports (MTRs).

– Verify compliance with relevant standards (e.g., ASTM, ISO).

– Conduct independent testing when high reliability is required.

– Perform IP due diligence when using specialty fastener designs.

– Maintain traceability throughout the supply chain.

Avoiding these pitfalls ensures that 1/2-inch bolts perform safely and legally in their intended applications.

H2: Logistics & Compliance Guide for 1/2″ Bolt Head Size

Proper handling, transportation, and regulatory compliance are essential when dealing with fasteners like 1/2″ bolt heads. This guide outlines key logistics and compliance considerations to ensure safe, efficient, and legal operations.

H3: Packaging & Handling

Standard Packaging:

– Bulk: Typically supplied in cartons, fiberboard drums, or steel/wooden crates depending on quantity and weight.

– Counted Units: Often packed in polybags, blister packs, or smaller cartons for retail or precision applications.

– Palletization: Bulk shipments are unitized on standard 48″ x 40″ pallets, secured with stretch wrap and corner boards. Max pallet height should not exceed 72″ unless specified.

Handling Guidelines:

– Use mechanical aids (forklifts, pallet jacks) for loads exceeding 50 lbs.

– Protect from moisture and contamination; store indoors in a dry, climate-controlled environment.

– Avoid dropping or impacting packages to prevent deformation or damage to threads.

H3: Transportation Requirements

Domestic (U.S.):

– Comply with Department of Transportation (DOT) regulations for general freight.

– Use freight classification code 301590 (Steel Bolts and Nuts) under NMFC.

– Secure loads per FMCSA standards to prevent shifting during transit.

International:

– Export Documentation: Include commercial invoice, packing list, and Harmonized System (HS) code 7318.15.50 (Steel bolts with forged heads, diameter ≤ 6mm — verify exact classification based on material and finish).

– Packaging: Must meet ISPM 15 standards if using wooden crates or pallets (heat-treated and stamped).

– Incoterms: Clearly define responsibilities (e.g., FOB, CIF) in contracts to avoid disputes.

H3: Regulatory Compliance

Material & Safety Standards:

– Ensure bolts meet ASTM, SAE, or ISO specifications (e.g., ASTM A325 for structural bolts).

– RoHS and REACH compliance required if exporting to EU; confirm no restricted substances (e.g., lead, cadmium) in plating.

– Conflict minerals reporting may apply under SEC Rule 13p-1 if sourced from covered regions.

Labeling & Marking:

– Head markings must indicate grade (e.g., three radial lines for Grade 5), manufacturer ID, and standard (per ASME B18.2.1).

– Shipping labels must include: Part number, quantity, net weight, and handling symbols (e.g., “Fragile,” “This Side Up”).

H3: Storage & Inventory

- Shelf Life: Indefinite if stored properly; inspect for corrosion every 6 months.

- Inventory Rotation: Use FIFO (First-In, First-Out) to prevent material aging.

- Environment: Maintain relative humidity below 60% to prevent rust; avoid contact with dissimilar metals.

H3: Special Considerations

- Hazardous Materials: Not typically classified as hazardous, but oily or plated variants may require SDS (Safety Data Sheet) under OSHA HAZCOM.

- Customs Clearance: Provide mill test reports or certs of conformance upon request to expedite processing.

- Traceability: Maintain lot tracking for quality control and recall readiness.

By adhering to this guide, you ensure compliance with industry and regulatory standards while optimizing the logistics chain for 1/2″ bolt head components. Always consult specific supplier data and regional regulations for project-specific requirements.

Conclusion for Sourcing 1/2″ Bolt Head Size:

After evaluating availability, standardization, and application requirements, sourcing a 1/2″ bolt head size is both practical and advantageous. This size conforms to widely accepted SAE (Society of Automotive Engineers) and ASTM (American Society for Testing and Materials) standards, ensuring compatibility with common tools and equipment. The 1/2″ bolt head is readily available from multiple suppliers and in various materials (e.g., stainless steel, grade 5, grade 8), making it suitable for diverse industrial, construction, and mechanical applications. Its balance of strength, ease of installation, and cost-effectiveness supports reliable performance in moderate to high-torque scenarios. Therefore, sourcing 1/2″ bolt heads is recommended for applications requiring a robust, standardized fastening solution with broad supply chain support.

![[PDF] printable](https://www.fobsourcify.com/wp-content/uploads/2026/01/pdf-printable-658.jpg)