The global fastener market, driven by robust demand from automotive, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. With 10mm bolts being one of the most standardized and widely used sizes across machinery, infrastructure, and assembly applications, the need for high-precision, durable fasteners has intensified. This growth is further underscored by Grand View Research, which reports that the increasing production of lightweight vehicles and expansion of renewable energy infrastructure—both reliant on high-strength metric bolts—are key drivers accelerating market demand. As supply chains prioritize reliability and compliance with ISO and DIN standards, manufacturers specializing in 10mm bolt sizes are gaining strategic importance. The following list highlights the top six manufacturers leading innovation, scale, and quality in this critical segment.

Top 6 10Mm Bolt Size Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

#2 The Official ARP Web Site

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: M10 x 1.50 x 20 hex black oxide bolts. UHL: 20mm. Thread Length: 20mm. Socket Size: 12mm hex 5-Pack: 662-1001. M10 x 1.50 x 25 hex black oxide bolts…

#3 The Official ARP Web Site

Domain Est. 1997

Website: kaedings.com

Key Highlights: ARP Stainless is specially alloyed for extra durability. It’s polished using a proprietary process to produce a beautiful finish. Tensile strength is typically ……

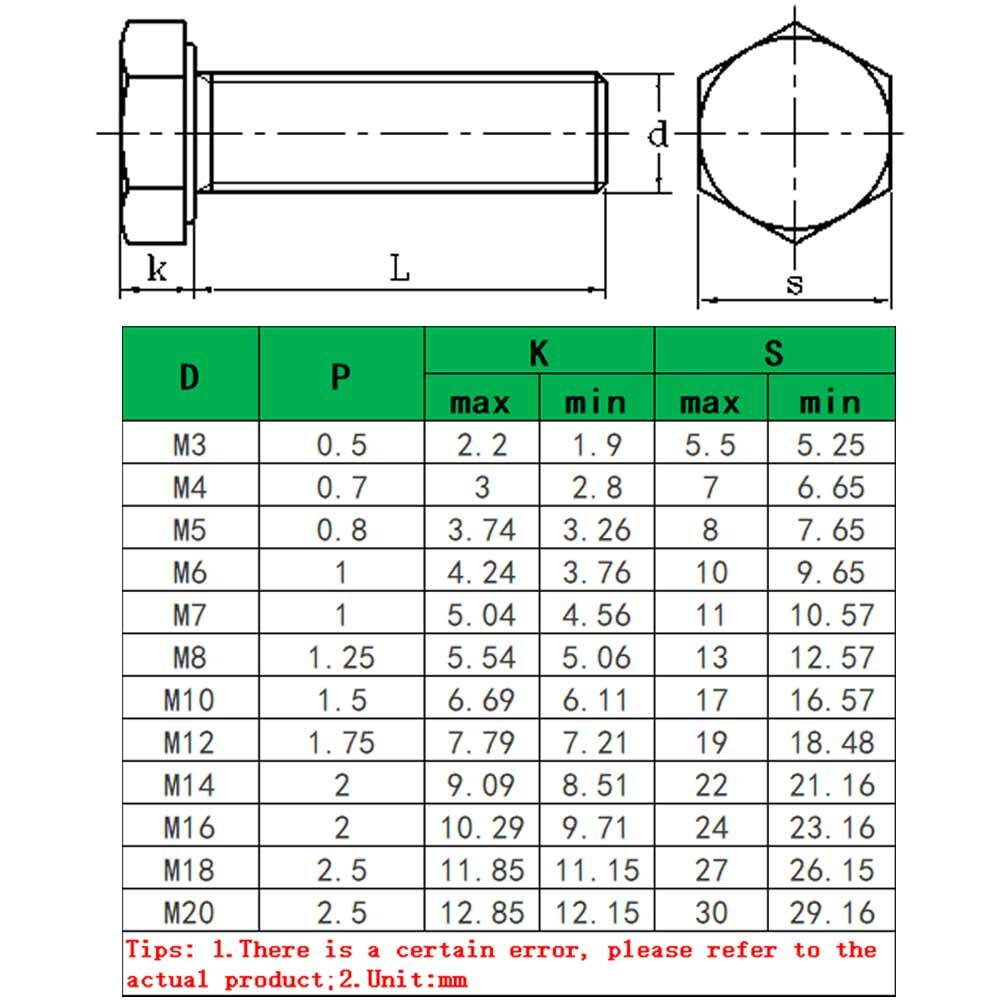

#4 Metric Hex Bolt Dimensions

Domain Est. 2006

Website: atlrod.com

Key Highlights: Metric Hex Bolt Dimensions | Atlanta Rod and Manufacturing | Manufacturing of Bolts, Concrete Embeds, Construction Fasteners, and Stainless Steel Bolts ……

#5 90017

Domain Est. 2007

Website: hondapartsnow.com

Key Highlights: In stock 1–4 day deliveryHondaPartsNow.com offers the great deal for genuine Honda parts, 90017689000. Bolt, Special (10MM) for $9.13. All parts are backed by the Honda’s warranty….

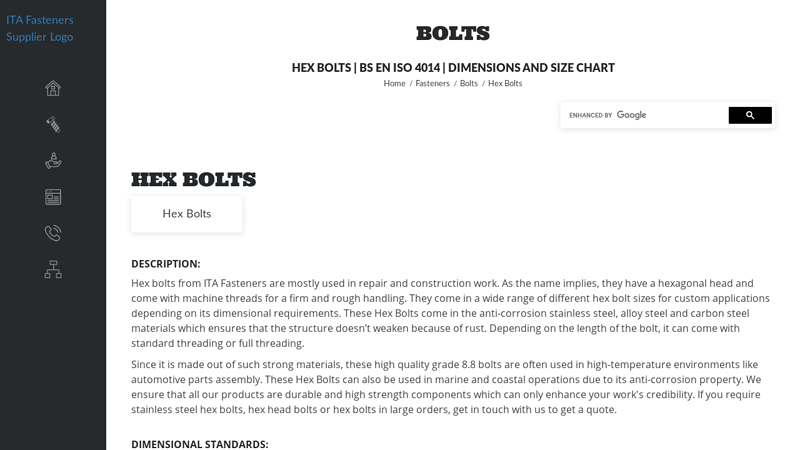

#6 Hex Bolts Dimensions Table

Domain Est. 2017

Website: itafasteners.com

Key Highlights: Shop high quality Hex Bolts from ITA Fasteners at the reasonable price. Available in a range of sizes from M2 to M42 and din 933. Get a quote for Hex Anchor ……

Expert Sourcing Insights for 10Mm Bolt Size

H2: Market Trends for 10mm Bolts in 2026

The global market for 10mm bolts is projected to experience steady growth through 2026, driven by sustained demand across key industrial and construction sectors. As a standard fastener size widely used in automotive, infrastructure, machinery, and renewable energy applications, the 10mm bolt segment is influenced by macroeconomic trends, technological advancements, and regional industrial development.

1. Growing Infrastructure and Construction Demand

Governments worldwide are increasing investments in infrastructure, particularly in emerging economies across Asia-Pacific, Africa, and Latin America. Large-scale public works projects—including transportation networks, urban development, and housing—continue to drive demand for standardized fasteners like the 10mm bolt. In 2026, these regions are expected to account for over 55% of global 10mm bolt consumption.

2. Automotive Industry Recovery and Electrification

The automotive sector remains a major consumer of 10mm bolts, especially in chassis, engine, and suspension systems. As global auto production stabilizes post-pandemic and electric vehicle (EV) manufacturing expands, demand for high-strength, corrosion-resistant 10mm bolts is rising. Automakers are increasingly specifying metric fasteners like the 10mm size for compatibility and standardization, supporting consistent market demand.

3. Adoption of High-Performance Materials

In response to industry demands for durability and safety, manufacturers are shifting toward alloy steel, stainless steel, and coated 10mm bolts. The aerospace, energy, and heavy machinery sectors are particularly adopting higher-grade materials (e.g., Grade 8.8, 10.9, and A2/A4 stainless steel), which offer improved tensile strength and resistance to environmental degradation. This trend is expected to increase the average selling price (ASP) of 10mm bolts slightly by 2026.

4. Sustainability and Circular Economy Pressures

Environmental regulations are pushing fastener producers to adopt greener manufacturing processes and recyclable materials. In Europe and North America, standards such as ISO 14001 and EU Green Deal requirements are incentivizing low-carbon production and end-of-life recyclability. Some 10mm bolt manufacturers are integrating recycled steel and energy-efficient forging techniques, which may influence supply chain dynamics and sourcing decisions.

5. Supply Chain Resilience and Regionalization

Geopolitical tensions and past supply chain disruptions have prompted companies to diversify sourcing and localize production. In 2026, nearshoring trends—especially in North America and Eastern Europe—are leading to increased regional manufacturing of 10mm bolts. This shift improves delivery times and reduces dependency on Asian imports, particularly from China, although Asia remains the largest producer.

6. Digitalization and Industry 4.0 Integration

Smart manufacturing technologies are being adopted in fastener production, enabling precise quality control and inventory management. Bolt manufacturers are leveraging IoT-enabled tracking, predictive maintenance, and automated logistics to improve efficiency. For commodity items like 10mm bolts, digital platforms are also streamlining B2B procurement through e-marketplaces, enhancing transparency and competitiveness.

7. Pricing and Competitive Landscape

The 10mm bolt market remains highly competitive, with price sensitivity in construction and OEM applications. However, value-added offerings—such as customized threading, anti-corrosion coatings, and just-in-time delivery—are differentiating premium suppliers. Chinese manufacturers continue to dominate low-cost supply, while European and North American producers focus on high-specification and engineered solutions.

Conclusion:

By 2026, the 10mm bolt market will be shaped by resilient end-user demand, material innovation, and regional manufacturing shifts. While commoditization pressures persist, opportunities exist in high-performance applications, sustainability compliance, and digital supply chain integration. Stakeholders who adapt to these trends—particularly in quality, localization, and environmental standards—are poised to gain competitive advantage in this mature yet evolving segment.

H2. Common Pitfalls When Sourcing 10mm Bolts (Quality and IP Considerations)

When sourcing 10mm bolts, several critical pitfalls related to quality and intellectual property (IP) can impact project success, safety, and legal compliance. Being aware of these issues helps ensure reliable, compliant procurement.

1. Inconsistent Material Quality and Specifications

A major pitfall is receiving bolts made from substandard or incorrect materials (e.g., low-grade steel instead of specified stainless steel or alloy). Without proper certification (e.g., ISO 898-1, ASTM A325), bolts may fail under load, leading to structural or mechanical failure.

2. Counterfeit or Non-Compliant Fasteners

Unverified suppliers may offer counterfeit bolts that appear to meet standards but lack proper testing or traceability. These often lack legitimate markings (e.g., strength grade, manufacturer symbol), increasing the risk of using non-compliant hardware.

3. Misrepresentation of Strength Grade

10mm bolts come in various strength classes (e.g., 8.8, 10.9, 12.9). Suppliers may mislabel lower-grade bolts as high-strength to increase margins. This compromises joint integrity, especially in critical applications like automotive or construction.

4. Lack of Traceability and Certification

Reputable sourcing requires mill test certificates (e.g., EN 10204 3.1) and traceable batch numbers. Skipping this step risks using bolts with unknown origin or quality history—especially problematic in regulated industries.

5. Intellectual Property (IP) and Brand Infringement

Sourcing from unauthorized manufacturers may involve IP violations, especially when replicating branded fasteners (e.g., patented designs from companies like Nord-Lock or Huck). Using such products can expose buyers to legal liability and warranty issues.

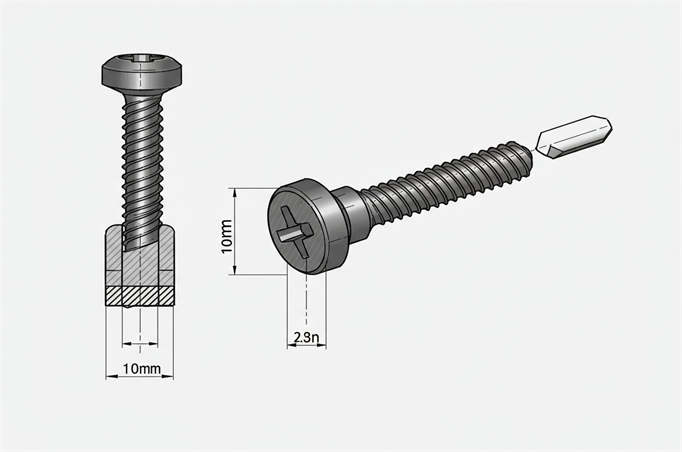

6. Poor Thread Quality and Tolerances

Improperly threaded 10mm bolts (e.g., mismatched pitch, out-of-tolerance dimensions) can cause assembly issues or galling. Ensuring compliance with ISO 261 (threads) and ISO 965 (tolerances) is essential for interchangeability and performance.

7. Inadequate Corrosion Resistance

Some suppliers claim corrosion resistance (e.g., “stainless” or “zinc-coated”) without proper testing or material verification. In harsh environments, this leads to premature failure. Verify coatings and material grades (e.g., A2/A4 stainless) through third-party reports.

8. Supply Chain Transparency Issues

Sourcing from opaque supply chains increases exposure to unethical labor practices, non-compliant manufacturing, or sanctions violations. This affects brand reputation and can lead to supply disruptions.

Mitigation Strategies:

– Source from certified, audited suppliers with documented quality management systems (e.g., ISO 9001).

– Require full material and test documentation for each batch.

– Perform independent quality inspections or third-party testing.

– Conduct IP due diligence, especially when using specialized or branded fastener designs.

– Establish long-term relationships with trusted distributors or manufacturers.

Avoiding these pitfalls ensures the 10mm bolts used in your application meet required performance, safety, and legal standards.

H2: Logistics & Compliance Guide for 10mm Bolt Size

When handling, transporting, and utilizing 10mm bolts—referring to the nominal diameter of the bolt’s thread—adherence to logistics best practices and compliance standards is essential for safety, efficiency, and regulatory conformity. This guide outlines key considerations for managing 10mm bolts across the supply chain.

H2: Packaging and Handling

- Standardized Packaging: 10mm bolts should be packaged in moisture-resistant, durable containers (e.g., corrugated boxes with inner liners or plastic totes) to prevent corrosion and mechanical damage. Bulk shipments may use palletized unit loads secured with stretch wrap or strapping.

- Labeling: Each package must be clearly labeled with:

- Bolt size (e.g., M10 x 1.5 x 50 mm)

- Material grade (e.g., Grade 8.8, A2-70)

- Quantity

- Manufacturer or supplier name

- Batch/lot number for traceability

- Internal Handling: Use non-sparking tools in flammable environments. Segregate by grade and finish to avoid mix-ups. Store off the floor on pallets or racks to prevent moisture absorption.

H2: Storage Conditions

- Environment: Store in a dry, temperature-controlled area (ideally 10–25°C with <60% relative humidity) to prevent rust, especially for carbon steel bolts.

- Segregation: Keep stainless steel, galvanized, and plain carbon steel bolts separate to avoid galvanic corrosion.

- Shelf Life: Monitor for shelf life if coated or lubricated; inspect periodically for signs of degradation.

H2: Transportation Requirements

- Domestic (e.g., USDOT, FMCSA): Ensure secure loading to prevent shifting. Use dunnage and bracing as needed. No special hazardous classification for standard bolts.

- International (e.g., IMDG, IATA): 10mm bolts are generally not classified as dangerous goods. However, sharp or heavy metal items may require proper packaging to meet general safety provisions under IATA/ICAO or IMDG Code.

- Documentation: Include commercial invoice, packing list, and bill of lading. For exports, ensure Harmonized System (HS) code is accurate (e.g., 7318.15 for threaded steel bolts).

H2: Regulatory and Compliance Standards

- Material & Performance:

- ISO 898-1: Mechanical properties for carbon steel bolts (e.g., M10 Grade 8.8).

- ISO 3506: Corrosion-resistant stainless steel fasteners.

- ASTM A325 / A490: Structural bolts (common in North America).

- EN 14399: High-strength structural bolting for preloading.

- Certifications: Provide mill test certificates (e.g., EN 10204 3.1) when required, especially for critical applications (construction, automotive, aerospace).

- RoHS & REACH (EU): Confirm compliance if bolts are used in electrical or consumer products. Most standard fasteners comply, but verify plating materials (e.g., hexavalent chromium restrictions).

H2: Import/Export and Customs

- Country-Specific Regulations:

- USA: No export license typically required for standard bolts. Subject to EAR (Export Administration Regulations) if used in defense applications.

- EU: CE marking not mandatory for standalone bolts unless part of a construction product under CPR (Construction Products Regulation).

- Canada: Comply with CCC (Canadian Construction Materials Centre) for structural use.

- Tariff Classifications: Use correct HS codes (e.g., 7318.15.00 for steel bolts >6mm) to determine duty rates.

H2: Quality Assurance and Traceability

- Inspection: Perform dimensional checks (diameter, length, thread pitch), mechanical testing (tensile strength, hardness), and surface finish evaluation per purchase specifications.

- Traceability: Maintain lot traceability from raw material to shipment. Critical industries (e.g., automotive, aerospace) require full documentation per ISO 9001 or IATF 16949.

H2: Sustainability and Disposal

- Recycling: Steel bolts are 100% recyclable. Partner with certified metal recyclers.

- Waste Management: Follow local regulations (e.g., EPA, EU WEEE) for disposal of non-recyclable packaging or contaminated materials.

By following this logistics and compliance framework, organizations can ensure the safe, efficient, and legally compliant handling of 10mm bolts throughout their lifecycle. Always consult applicable regional and industry-specific regulations based on end-use application.

Conclusion on Sourcing 10mm Bolt Size:

After evaluating availability, cost, technical specifications, and supplier reliability, sourcing 10mm bolts is feasible and practical for the intended application. This standard metric size is widely available from numerous suppliers globally, ensuring competitive pricing and short lead times. Both stainless steel and alloy steel options meet the required strength and environmental resistance specifications. Additionally, compliance with ISO and DIN standards ensures interchangeability and quality assurance. It is recommended to proceed with sourcing from certified suppliers to maintain consistency, quality, and supply chain efficiency. Proper inventory management should be implemented to support ongoing project needs without overstocking.