The global fastener market, driven by robust demand from automotive, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of 5.2% from 2023 to 2030, according to Grand View Research. With increasing infrastructure development and the expansion of electric vehicle production, high-strength bolts—particularly those rated at 10.9 grade—are witnessing heightened demand due to their superior tensile strength and reliability under stress. As industries prioritize performance and safety, the need for precision-engineered 10.9 grade bolts has elevated the prominence of leading manufacturers capable of consistent quality and large-scale output. This list highlights the top eight manufacturers excelling in the production of 10.9 bolt grade fasteners, selected based on production capacity, global reach, compliance with ISO and DIN standards, and innovation in material science.

Top 8 10.9 Bolt Grade Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

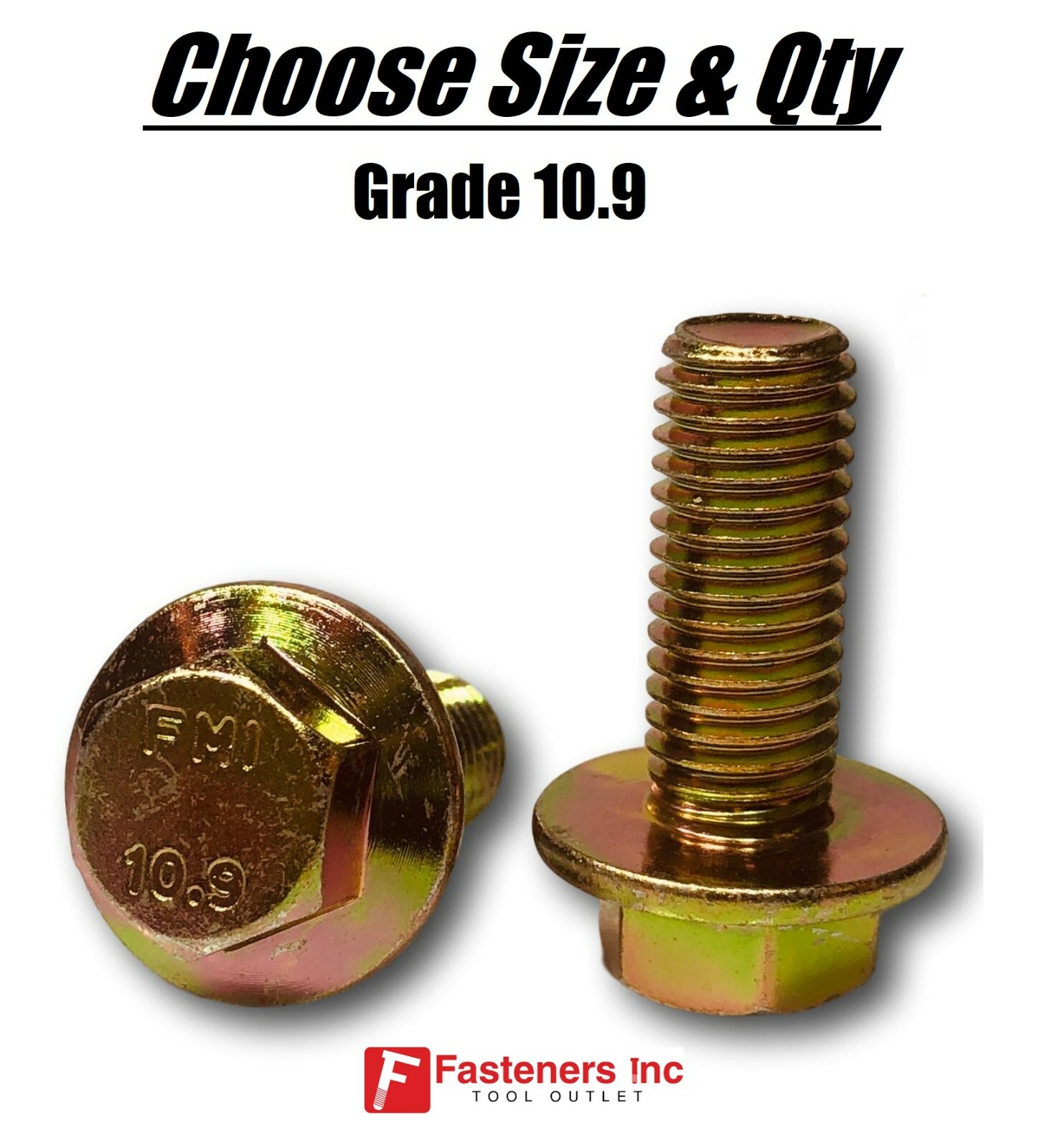

#1 Replacement Metric Flange Bolt

Domain Est. 2014

Website: ictbillet.com

Key Highlights: In stock $23.79 deliveryBolts are made in the USA!! Grade 10.9 strength – Stronger than Grade 8 for dependable performance. Factory LS head size – Matches OEM specs for a seamless …

#2 ASTM F568 Grade Class 10.9 Fasteners Manufacturer & Exporter

Domain Est. 2005

Website: amcometals.com

Key Highlights: We offer 10.9 Grade Heavy Hex Bolts that are rust resistant and used for structural connections. We keep a tab on market courses and needs, to invent new, ……

#3 Hex Bolts 10.9

Domain Est. 1998

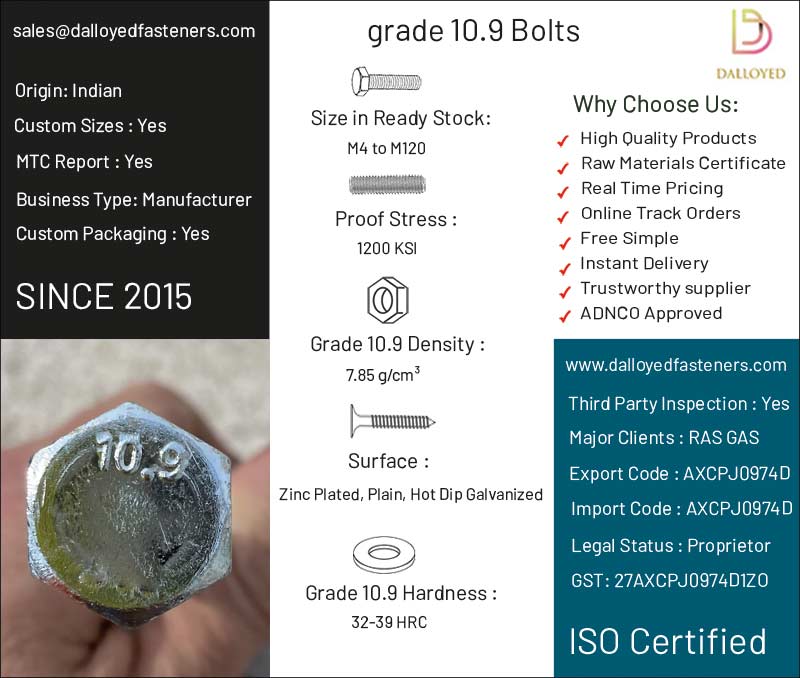

#4 Grade 10.9 Bolts

Domain Est. 1999

Website: uboltit.com

Key Highlights: Grade 10.9 metric bolts are manufactured using medium carbon steel, medium carbon steel alloy and low carbon boron steel that has been quenched and tempered….

#5 Metric hex bolts, Zinc plated class 10.9 steel, 16mm x 2.0mm x 75mm

Domain Est. 1999

#6 Grade 10.9 Bolt

Domain Est. 2011

Website: navstarsteel.com

Key Highlights: Grade 10.9 Bolt is a high tensile bolt. These are made up of carbon steels and low boron steels. The material is heat treated by quenched and tempered methods….

#7 High Tensile Grade 10.9 Hex Bolt, Stud & Threaded Rod

Domain Est. 2018

Website: textronsteelalloys.com

Key Highlights: Hardened Class 10.9 Metric Hex Bolts are a high strength, high tensile fastening solution available in coarse, fine and extra fine thread….

#8 Grade 10.9 Hex Bolts: A Complete Overview

Domain Est. 2020

Website: anankafasteners.com

Key Highlights: Rating 5.0 (451) Grade 10.9 Hex Bolts are highly strength fasteners that have a wide usage in industries which require highly durable and reliable components….

Expert Sourcing Insights for 10.9 Bolt Grade

H2: Projected 2026 Market Trends for 10.9 Bolt Grade Steel

The global market for Grade 10.9 bolts—high-strength fasteners made from quenched and tempered alloy or medium carbon steel—is anticipated to experience steady growth and transformation by 2026, driven by evolving industrial demands, technological advancements, and regional economic developments. Below is an analysis of key market trends expected to shape the 10.9 bolt grade sector in 2026.

1. Rising Demand from Automotive and Construction Sectors

The automotive industry remains a major consumer of Grade 10.9 bolts, particularly in engine components, suspension systems, and chassis assemblies. With the global push toward electric vehicles (EVs), manufacturers are leveraging high-strength fasteners to reduce vehicle weight while maintaining structural integrity. In parallel, infrastructure expansion in emerging economies—especially in Asia-Pacific and Africa—will fuel construction-related demand for high-tensile bolts used in steel frameworks, bridges, and industrial facilities.

2. Shift Toward Lightweight and High-Performance Materials

Although Grade 10.9 bolts are already high-performance components, there is increasing R&D focused on enhancing their fatigue resistance, corrosion protection, and compatibility with alternative materials (e.g., aluminum and composites). Surface treatments such as zinc-nickel coatings and duplex finishing are expected to gain traction to meet durability standards in harsh environments.

3. Regional Market Dynamics

Asia-Pacific, led by China, India, and Southeast Asia, will continue to dominate production and consumption due to robust manufacturing ecosystems and infrastructure investments. Europe maintains strong demand driven by stringent automotive safety regulations and renewable energy projects (e.g., wind turbine assembly). North America will see moderate growth, supported by reshoring of manufacturing and investments in clean energy infrastructure.

4. Supply Chain Resilience and Localization

Post-pandemic and geopolitical tensions have prompted companies to reevaluate supply chains. By 2026, there will be a greater emphasis on localized production of critical fasteners, including Grade 10.9 bolts, to reduce dependency on single-source suppliers. Nearshoring and vertical integration strategies are expected to become more common among tier-1 suppliers.

5. Sustainability and Regulatory Pressures

Environmental regulations are pushing manufacturers toward energy-efficient production processes and recyclable materials. Carbon footprint tracking and compliance with standards such as ISO 14001 and REACH will influence sourcing decisions. Bolt producers investing in green manufacturing (e.g., electric arc furnaces, reduced-emission heat treatment) will gain a competitive edge.

6. Digitalization and Smart Manufacturing

Industry 4.0 technologies—such as IoT-enabled quality control, predictive maintenance in production lines, and blockchain for traceability—are being adopted by leading fastener manufacturers. These innovations enhance consistency in producing Grade 10.9 bolts and support just-in-time delivery models demanded by OEMs.

7. Price Volatility of Raw Materials

Fluctuations in the prices of raw materials like high-carbon steel, chromium, and molybdenum may impact profit margins. Strategic sourcing, long-term supplier contracts, and investment in scrap recycling will be essential for cost management in 2026.

Conclusion

By 2026, the Grade 10.9 bolt market will be characterized by increased demand from high-tech and heavy industries, a focus on performance and sustainability, and a more resilient, regionally balanced supply chain. Companies that innovate in material science, adopt smart manufacturing practices, and respond to regulatory and environmental challenges will be best positioned to lead the market.

Common Pitfalls When Sourcing 10.9 Bolt Grade (Quality, IP)

Sourcing 10.9 grade bolts—high-strength fasteners commonly used in critical structural, automotive, and industrial applications—can present several challenges related to quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps ensure product reliability, compliance, and legal safety.

Inadequate Quality Verification and Certification

One of the most significant risks when sourcing 10.9 bolts is receiving substandard products that do not meet mechanical or chemical specifications. Many suppliers, especially in low-cost regions, may claim compliance with ISO 898-1 or ASTM A325/A490 standards without proper testing or traceability. Buyers may encounter falsified mill test certificates (MTCs), inconsistent heat treatment, or use of inferior raw materials. Without third-party inspection or batch testing, non-conforming bolts can lead to structural failures, safety hazards, and costly recalls.

Counterfeit or Misrepresented Products

The high demand for 10.9 bolts makes them a target for counterfeiting. Some suppliers may stamp lower-grade bolts (e.g., 8.8) with 10.9 markings to deceive buyers. This misrepresentation bypasses proper quality controls and undermines design integrity. Without rigorous supplier vetting and material verification (e.g., tensile testing, hardness checks), organizations risk integrating compromised components into critical assemblies.

Lack of Traceability and Documentation

Proper traceability—including heat numbers, manufacturing batch data, and certification documentation—is essential for quality assurance and compliance, especially in regulated industries. Many suppliers fail to provide complete documentation, making it difficult to verify origin, production methods, or conformity to standards. This lack of transparency can complicate audits, liability assessments, and root-cause analysis during failure investigations.

Intellectual Property Risks in Custom or Proprietary Designs

When sourcing custom-designed 10.9 bolts (e.g., unique thread profiles, coatings, or geometries), IP exposure is a key concern. Unsecured supplier agreements may allow manufacturers to replicate or resell proprietary designs to competitors. Buyers often overlook the need for non-disclosure agreements (NDAs), clear IP ownership clauses, and secure design transfer protocols, leaving innovations vulnerable to theft or unauthorized use.

Inconsistent Coatings and Corrosion Protection

While not always considered, surface treatments such as zinc plating, Geomet, or Dacromet must meet specified thickness and performance standards to prevent hydrogen embrittlement and corrosion. Poorly applied coatings on high-strength bolts can lead to premature failure. Suppliers may cut corners on post-plating baking processes or use substandard materials, compromising long-term performance despite apparent compliance.

Mitigation Strategies

To avoid these pitfalls, implement a robust sourcing strategy including verified supplier audits, independent material testing, secure contractual IP protections, and full documentation requirements. Engaging reputable certification bodies and maintaining control over design and specification release can significantly reduce quality and IP risks.

Logistics & Compliance Guide for 10.9 Bolt Grade

Overview of 10.9 Bolt Grade

The 10.9 bolt grade is a high-strength metric fastener commonly used in structural, automotive, and heavy machinery applications. The designation “10.9” refers to its mechanical properties: a tensile strength of approximately 1000 MPa and a yield strength of 900 MPa (90% of tensile strength). These bolts are typically made from alloy steel and are quenched and tempered to achieve their strength. Understanding their specifications is crucial for logistics planning and regulatory compliance.

Material & Manufacturing Standards

10.9 bolts must conform to recognized international standards such as ISO 898-1, which specifies mechanical properties for bolts, screws, and studs made of carbon steel and alloy steel. Compliance with ASTM A325 or ASTM A490 may also be required in certain regions, particularly in structural steel construction in North America. Manufacturers must provide certification (e.g., ISO 17025, EN 10204 3.1) to verify material composition and mechanical testing results.

Packaging & Handling Requirements

Proper packaging is essential to prevent corrosion and mechanical damage during transit. 10.9 bolts should be:

– Packaged in moisture-resistant, sealed containers or wrapped with VCI (Vapor Corrosion Inhibitor) paper.

– Segregated by size, length, and coating type to avoid mix-ups.

– Labeled clearly with part number, grade (10.9), material standard, batch/lot number, and country of origin.

– Stored in dry, temperature-controlled environments to prevent hydrogen embrittlement, especially for plated components.

Transportation & Storage

Due to their high strength and critical applications, 10.9 bolts must be handled with care:

– Use non-abrasive handling methods to avoid surface damage.

– Avoid exposure to moisture, salt, or corrosive environments during transport.

– Store in a clean, dry warehouse with controlled humidity to prevent rust.

– Observe stacking limits to prevent deformation of packaging and damage to fasteners.

Regulatory & Safety Compliance

Transportation of 10.9 bolts may fall under general industrial goods regulations, but compliance with regional safety and quality standards is mandatory:

– EU: Must comply with Construction Products Regulation (CPR) when used in construction; CE marking may be required.

– USA: Subject to ASTM and DOT regulations when used in transportation infrastructure.

– RoHS & REACH: Ensure coatings (e.g., zinc plating, dacromet) comply with environmental and chemical restrictions.

– ITAR/EAR: Not typically controlled, but verify if bolts are used in defense or aerospace applications.

Documentation & Traceability

Full traceability is required for quality assurance and recall management:

– Maintain batch-specific mill test certificates (MTCs) and inspection reports.

– Include heat number, manufacturing date, and testing data in shipping documentation.

– Use barcode or RFID labeling for inventory and compliance tracking.

– Retain records for a minimum of 10 years, especially for structural and safety-critical applications.

Inspection & Quality Control

Incoming and outgoing inspections should verify:

– Mechanical properties via tensile and hardness testing.

– Dimensional accuracy per ISO 4014, ISO 4017, or customer specifications.

– Surface finish and coating thickness (e.g., zinc plating ≥ 8–12 µm).

– Absence of cracks, laps, or other manufacturing defects.

Third-party testing or certification may be required for high-risk applications.

End-of-Life & Recycling Compliance

10.9 bolts are typically 100% recyclable:

– Steel bolts can be processed in standard scrap metal recycling streams.

– Coatings such as zinc or cadmium may require specialized handling—ensure compliance with local hazardous waste regulations.

– Follow WEEE or ELV directives in Europe if part of electrical or automotive assemblies.

Summary

Effective logistics and compliance for 10.9 bolt grade require adherence to international standards, proper handling and packaging, complete documentation, and strict quality control. Ensuring regulatory compliance across regions and maintaining traceability throughout the supply chain are critical to supporting safety, performance, and legal requirements in high-stress applications.

Conclusion for Sourcing 10.9 Grade Bolts:

In conclusion, sourcing 10.9 grade bolts requires a strategic approach focused on quality, compliance, and supplier reliability. The 10.9 grade designation indicates high tensile strength (approximately 1000 MPa ultimate tensile strength, 900 MPa yield strength), making these bolts suitable for critical structural, automotive, machinery, and heavy industrial applications where high strength and durability are essential.

Key considerations in the sourcing process include verifying material certifications (such as ISO 898-1 or ASTM A574), ensuring proper heat treatment and manufacturing standards, and confirming dimensional accuracy and thread quality. It is crucial to partner with reputable suppliers or manufacturers who adhere to international standards and can provide traceability and test reports.

Cost should not be the sole deciding factor—compromising on quality can lead to component failure, safety hazards, and higher long-term costs. Additionally, evaluating logistics, lead times, and minimum order requirements ensures smooth integration into production or construction timelines.

Ultimately, successful sourcing of 10.9 grade bolts balances performance requirements, regulatory compliance, and supply chain efficiency, supporting the integrity and reliability of the final assembly or structure. Regular quality audits and supplier evaluations will further ensure consistent product performance and mitigate risks in critical applications.