The global plexiglass (polymethyl methacrylate, or PMMA) sheets market has experienced steady growth driven by rising demand across construction, automotive, signage, and consumer electronics sectors. According to a 2023 report by Mordor Intelligence, the global PMMA market was valued at USD 5.94 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028. This expansion is fueled by the material’s superior clarity, lightweight properties, and resistance to UV radiation and weathering, making it a preferred alternative to traditional glass in a wide range of applications. Additionally, Grand View Research reported that increasing infrastructure development in emerging economies and the growing adoption of acrylic sheets in architectural glazing and interior design are key contributors to market momentum. As demand rises, a select group of manufacturers has emerged as leaders in innovation, scale, and product quality—setting the benchmark for performance and sustainability in the plexiglass industry.

Top 10 1 4 Plexiglass Sheets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Plexiglass Sheet

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: 3-day returnsWe will cut-to-size & ship sheets of plexiglass directly to your door. Buy plexiglass online or shop for various grades of plexiglass from our website….

#2 1/4″ x 24″ x 48″ (nominal) Clear Extruded Acrylic

Domain Est. 1997

Website: acmeplastics.com

Key Highlights: In stock Free deliveryClear extruded acrylic 24″ x 48″ x 1/4″ thick. Suitable for numerous varied projects, competitively priced mini-sheets eliminate the need for storage….

#3 Plastic, Acrylic & Polycarbonate Sheet Supplier

Domain Est. 1997

Website: acplasticsinc.com

Key Highlights: Our offering includes acrylic sheeting, plexiglass sheeting, polycarbonate sheeting, multiwall sheeting, abs plastic sheeting, HDPE and much more….

#4 Grafix Plastics

Domain Est. 1997

Website: grafixplastics.com

Key Highlights: Grafix Plastics is a quality plastic film and plastic sheets supplier and full-service material converter. Contact us to help you innovate with confidence!…

#5 Min Plastics

Domain Est. 2000

Website: minplastics.com

Key Highlights: Hawaiʻi’s trusted source for engineered plastics. Official distributor of PLEXIGLAS®, Polycarbonate, Expanded/Foamed PVC, HDPE, Starboard ……

#6 Delvie’s Plastics

Domain Est. 2002

Website: delviesplastics.com

Key Highlights: 4-day delivery 30-day returnsAcrylic plexiglass sheet, cut to size, in hundreds of colors and thicknesses. With an emphasis on customer service, low prices, and the highest quality…

#7 Acrylic Sheets (Plexiglass)

Domain Est. 2004

Website: canalplastic.com

Key Highlights: 4-day delivery 14-day returnsShop premium cast acrylic sheets at Canal Plastics. Clear, colored & frosted plexiglass. Custom cut-to-size. Mirror & iridescent are extruded….

#8 1/4″

Domain Est. 2004

Website: estreetplastics.com

Key Highlights: In stock 30-day returns1/4″ x 12″ x 36″ – Clear Acrylic Plexiglass Sheet – Extruded – (Film Mask) features: Good dimensional stability; Easy to flame polish; Significantly lighter …

#9 1/4″ Thick Clear Acrylic Plexiglass Sheet

Domain Est. 2010

Website: pleximart.com

Key Highlights: In stock $72.96 deliveryClear cast acrylic , 1/4” thick also commonly referred to as perspex sheet, is a high quality and versatile clear plastic sheet material offering high leve…

#10 Plexiglass Sheet

Domain Est. 2010

Expert Sourcing Insights for 1 4 Plexiglass Sheets

H2: 2026 Market Trends for 1/4-Inch Plexiglass Sheets

The global market for 1/4-inch plexiglass (acrylic) sheets is poised for steady growth and transformation by 2026, driven by evolving consumer demands, technological advancements, and sustainability initiatives. As industries and end-users increasingly seek lightweight, durable, and transparent alternatives to glass, plexiglass—particularly in the widely used 1/4-inch thickness—remains a material of choice across multiple sectors.

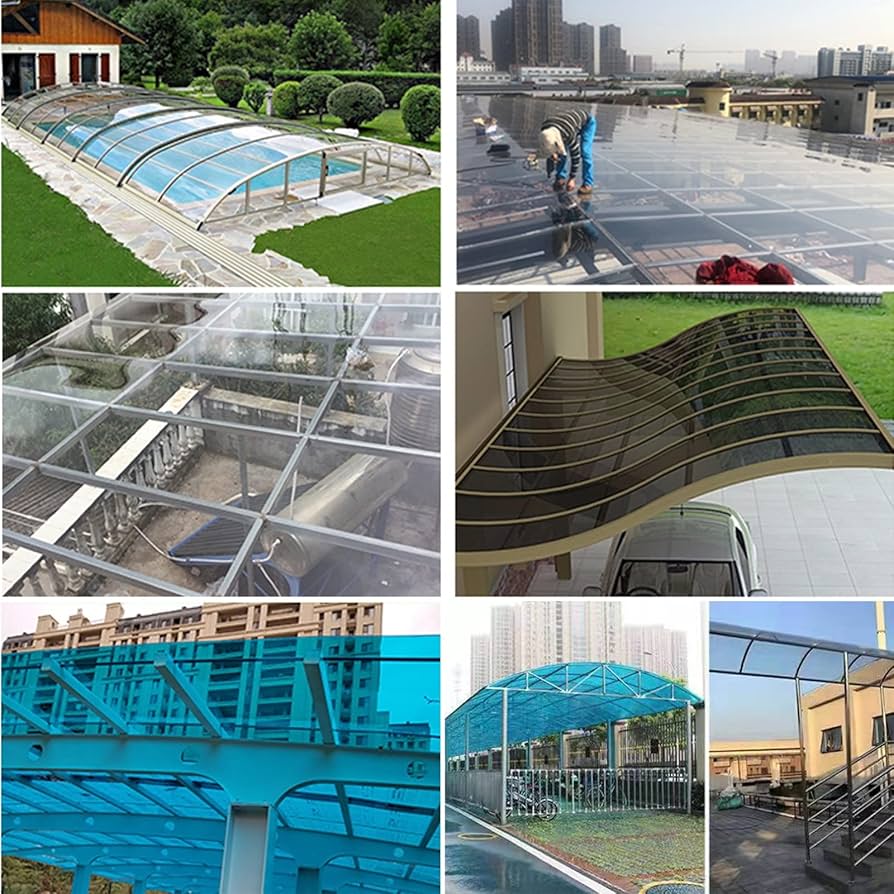

1. Increased Demand in Construction and Architecture

A major trend shaping the 2026 market is the rising adoption of 1/4-inch plexiglass in commercial and residential construction. Architects and designers are favoring acrylic sheets for skylights, partitions, façades, and safety barriers due to their high impact resistance and optical clarity. Urban development projects and green building standards are accelerating demand, especially in regions with strict energy efficiency codes, as plexiglass provides better insulation than traditional glass.

2. Growth in Retail and Display Applications

Retail environments continue to utilize 1/4-inch plexiglass for display cases, signage, and protective sneeze guards—a trend solidified during the pandemic and expected to persist. By 2026, the expansion of experiential retail and pop-up stores will further boost demand for customizable, easy-to-install acrylic solutions. The material’s ability to be laser-cut, engraved, and thermoformed supports innovative retail designs.

3. Sustainability and Recyclability Push

Environmental concerns are reshaping production and consumption patterns. Manufacturers are investing in recycled and bio-based plexiglass formulations to meet corporate sustainability goals and regulatory requirements. By 2026, eco-friendly 1/4-inch sheets are expected to capture a larger market share, especially in Europe and North America, where circular economy policies are gaining momentum.

4. Technological Integration and Smart Surfaces

Emerging applications integrate plexiglass with smart technologies, such as embedded LEDs, touch sensitivity, and anti-microbial coatings. The 1/4-inch thickness is ideal for balancing structural integrity and functionality in interactive kiosks, digital signage, and healthcare environments. This trend is anticipated to grow significantly by 2026, particularly in smart cities and IoT-driven infrastructure.

5. Supply Chain Resilience and Regional Manufacturing

Ongoing geopolitical tensions and logistics disruptions have prompted a shift toward localized production. By 2026, more suppliers are expected to establish regional manufacturing hubs to reduce lead times and dependency on global supply chains. This shift will enhance availability and reduce costs for end-users, especially in developing markets.

6. Price Volatility and Raw Material Challenges

Despite growth, the market may face headwinds from fluctuating prices of methyl methacrylate (MMA), the primary raw material for plexiglass. Energy costs and petrochemical market dynamics could lead to price volatility. However, advancements in alternative feedstocks and recycling technologies may help stabilize long-term pricing.

In conclusion, the 2026 outlook for 1/4-inch plexiglass sheets is optimistic, marked by innovation, sustainability, and diversification across industries. Companies that invest in eco-friendly materials, digital customization, and supply chain efficiency are likely to lead the market in the coming years.

Common Pitfalls When Sourcing 1/4″ Plexiglass Sheets (Quality & IP)

Sourcing 1/4″ Plexiglass (acrylic) sheets may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to project failures, safety issues, or legal complications. Here are the most common pitfalls to avoid:

Poor Optical Clarity and Surface Quality

One of the primary reasons for choosing Plexiglass is its transparency. However, low-quality sheets often suffer from inconsistent thickness, haze, wave patterns, or surface scratches that degrade optical performance. Off-brand or recycled acrylic may appear cloudy or have internal stresses that distort light. Always request samples to evaluate clarity and surface finish under real-world lighting conditions.

Inconsistent Sheet Thickness and Dimensional Accuracy

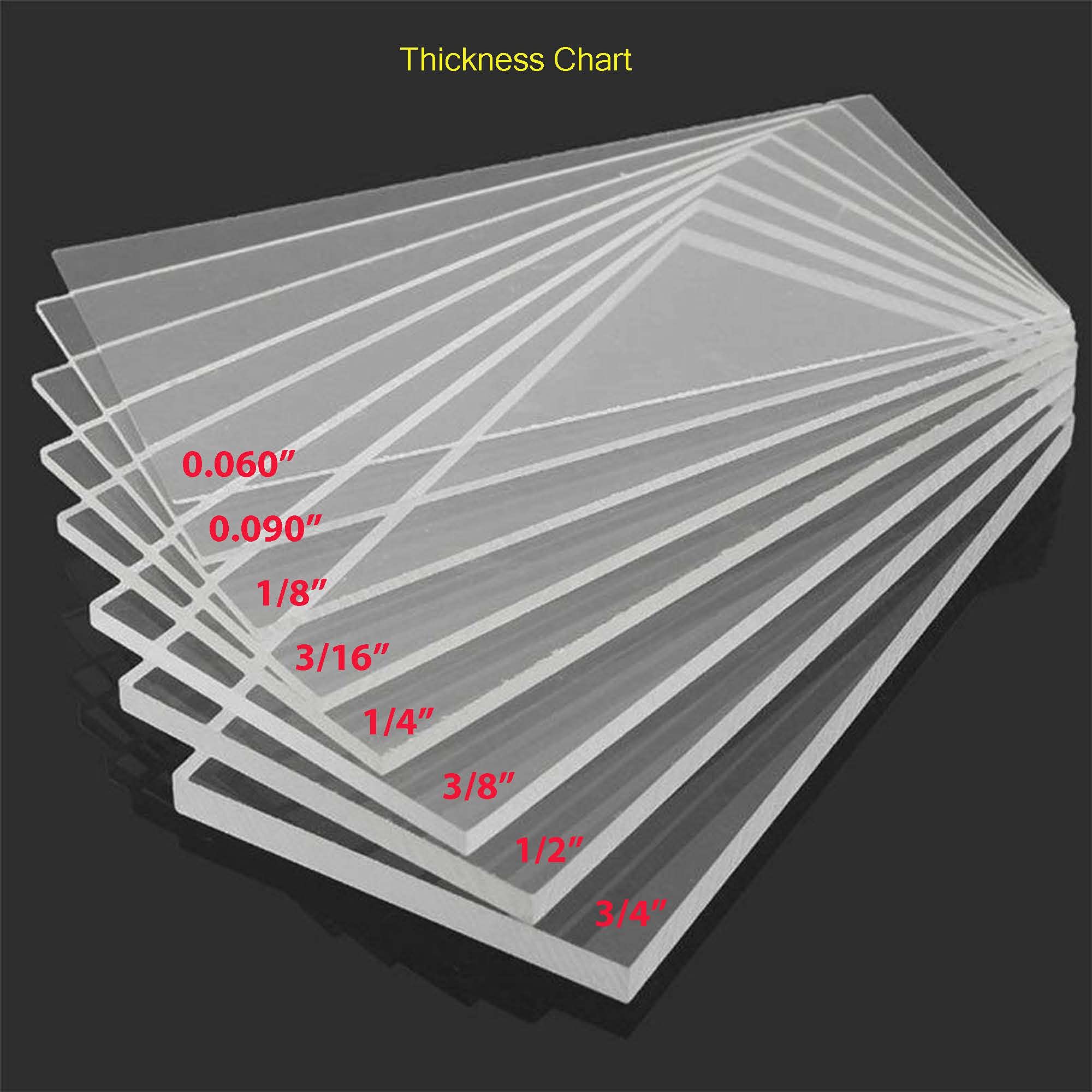

While 1/4″ (6.35 mm) is a standard thickness, cheaper suppliers may offer sheets that vary significantly—sometimes as thin as 5.5 mm. This inconsistency can compromise structural integrity, affect fit during installation, or interfere with machining and assembly. Verify tolerance specifications (e.g., ±0.2 mm) and insist on calibrated thickness measurements.

Use of Non-Cell-Cast Acrylic (Extruded Instead)

Cell-cast acrylic typically offers superior strength, scratch resistance, and optical clarity compared to extruded acrylic. Many low-cost suppliers use extruded sheets to cut costs, which are more prone to cracking under stress and exhibit lower thermal resistance. Ensure the material is specified as cell-cast (e.g., brand names like Plexiglas G, Acrylite GP) if performance is critical.

Lack of UV Resistance and Weatherability

Standard acrylic yellows and becomes brittle when exposed to prolonged sunlight. For outdoor applications, UV-stabilized or co-extruded acrylic is essential. Failing to verify UV protection can result in premature degradation. Check for certifications or manufacturer data sheets confirming outdoor suitability.

Ignoring Intellectual Property (IP) and Brand Authenticity

“Plexiglas” is a registered trademark of Röhm GmbH (sold under brands like Plexiglas®, Altuglas®, etc.). Many suppliers sell generic acrylic while misleadingly using the term “Plexiglas” to imply brand authenticity. This can mislead buyers into thinking they’re purchasing a high-performance, IP-protected product. Always confirm the actual brand and request documentation to avoid counterfeit or misrepresented materials.

Absence of Certification and Traceability

High-performance or safety-critical applications (e.g., signage, protective barriers, medical devices) may require compliance with standards such as ANSI, ASTM, or ISO. Generic sheets often lack certification, making them unsuitable for regulated environments. Ensure the supplier provides material test reports (MTRs) and traceable batch information.

Inadequate Scratch and Chemical Resistance

Not all acrylics are equally resistant to solvents, cleaners, or abrasion. Some off-brand sheets may degrade when exposed to common disinfectants or environmental pollutants. Confirm chemical resistance specifications, especially for industrial or healthcare applications.

Poor Supplier Reliability and Minimum Order Issues

Some suppliers may offer attractive pricing but fail to deliver on time or provide consistent quality across batches. Others impose high minimum order quantities (MOQs) that don’t align with project needs. Vet suppliers for reliability, scalability, and customer service before committing.

By paying close attention to material specifications, brand authenticity, and supplier credibility, you can avoid these common pitfalls and ensure you source high-quality, IP-compliant 1/4″ Plexiglass sheets suitable for your application.

Logistics & Compliance Guide for 1/4″ Plexiglass Sheets

Product Description and Specifications

1/4″ (6.35 mm) Plexiglass (acrylic) sheets are rigid, transparent thermoplastic panels commonly used in signage, displays, protective barriers, and architectural applications. They offer high optical clarity, weather resistance, and impact strength compared to glass. Standard sheet sizes typically include 48″ x 96″ (4′ x 8′), though custom dimensions may be available.

Packaging Requirements

Plexiglass sheets must be packaged to prevent surface scratches, cracking, and edge damage during transit. Each sheet should be protected with:

– A removable paper or film protective layer on both sides

– Corrugated cardboard corner guards or edge protectors

– Secure bundling with stretch wrap or strapping

– Placement within a rigid outer container or palletized with skid boards to avoid direct stacking

Handling and Storage Guidelines

- Always handle sheets with clean gloves to avoid fingerprints and surface contamination

- Lift using two or more people for standard 4′ x 8′ sheets to prevent bending or cracking

- Store vertically in a cool, dry environment away from direct sunlight and high heat sources

- Avoid placing heavy objects on stored sheets to prevent warping or stress fractures

Transportation and Shipping

- Secure sheets on pallets or in crates for freight transport

- Use straps or tie-downs to immobilize loads during transit

- Protect against moisture by covering with waterproof tarps or using enclosed trailers

- Clearly label shipments as “Fragile” and “This Side Up” to alert handlers

- For international shipments, comply with ISPM 15 regulations if wood pallets are used (heat-treated and stamped)

Regulatory Compliance

- Ensure product complies with relevant safety and material standards such as ASTM D4802 (for acrylic sheet properties)

- Provide Safety Data Sheet (SDS) in accordance with OSHA’s Hazard Communication Standard (29 CFR 1910.1200)

- Declare product as non-hazardous for transport under DOT 49 CFR when shipped in solid sheet form

- For export, include Harmonized System (HS) code 3920.51 for polymethyl methacrylate (PMMA) sheets

Environmental and Disposal Considerations

- Plexiglass is recyclable (Resin Identification Code #7 – “Other Plastics”)

- Dispose of off-cuts and waste in accordance with local, state, and federal environmental regulations

- Avoid incineration without proper emission controls, as burning acrylic can release harmful fumes

Documentation and Labeling

Include the following with each shipment:

– Packing list with item description, quantity, dimensions, and weight

– Certificate of Compliance (if applicable)

– SDS for workplace safety compliance

– Proper shipping labels with handling instructions and customer information

Special Considerations for International Shipments

- Verify customs requirements for destination country

- Provide accurate commercial invoice with declared value

- Confirm voltage and labeling requirements if sheets are part of a larger assembled product

- Use appropriate export-grade packaging to withstand extended transit times

In conclusion, sourcing 1/4-inch plexiglass (acrylic) sheets requires careful consideration of several key factors to ensure both quality and value. It is important to evaluate suppliers based on material quality, pricing, availability, shipping options, and customer service. Whether purchasing from local hardware stores, specialty plastics suppliers, or online retailers like Amazon, Home Depot, or Tap Plastics, comparing product specifications—such as clarity, UV resistance, and sheet dimensions—is essential for meeting project requirements.

Additionally, considering the intended application—whether for display cases, protective barriers, signage, or DIY projects—will influence the choice of finish (clear, frosted, or mirrored) and the need for additional features like anti-scratch coating. While local suppliers offer the advantage of immediate pickup and expert advice, online vendors often provide a broader selection and competitive pricing with delivery convenience.

Ultimately, balancing cost, quality, and convenience will lead to the most effective sourcing decision. By researching suppliers, reading customer reviews, and ordering samples when possible, you can ensure that the 1/4-inch plexiglass sheets meet your project’s needs efficiently and economically.