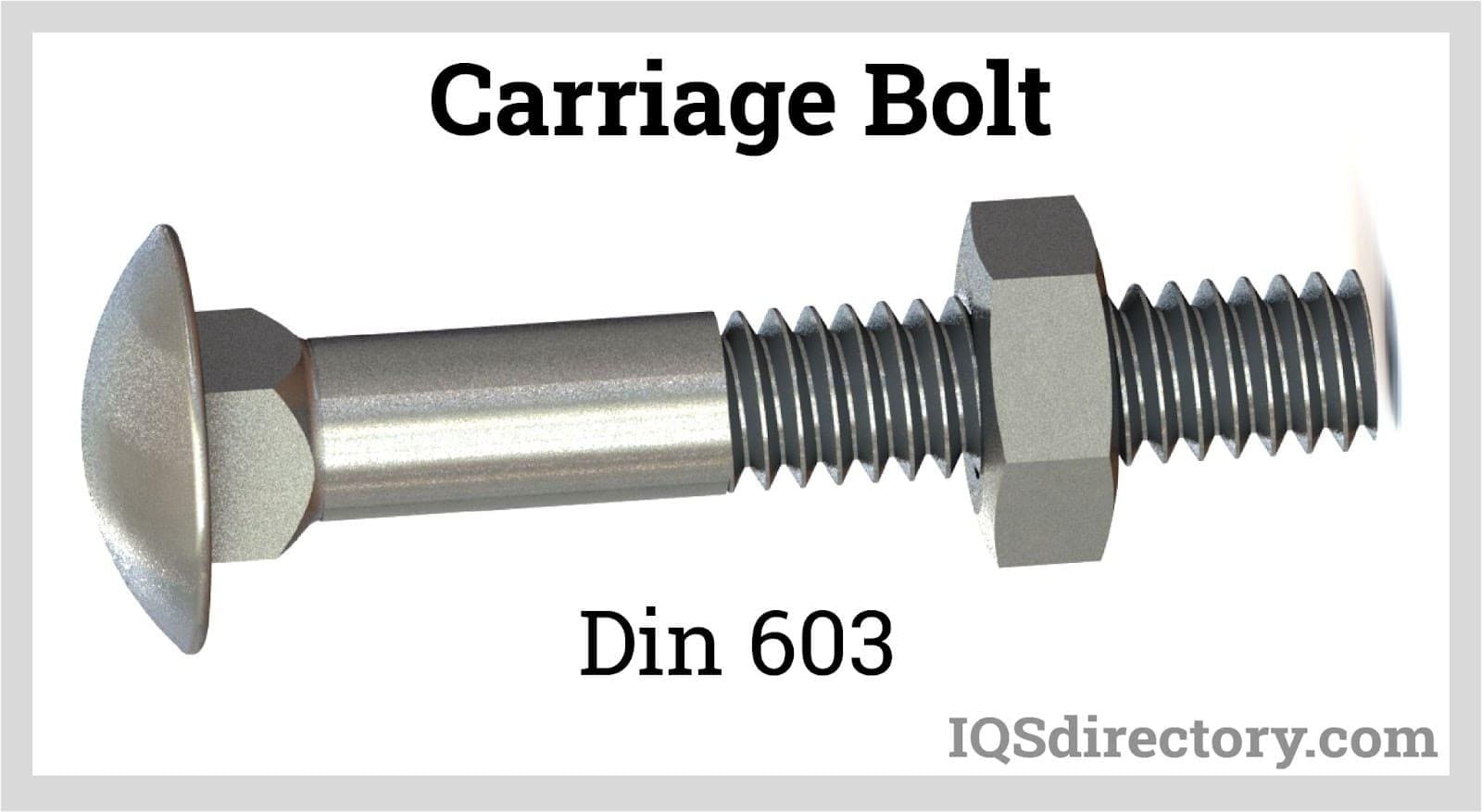

The global fasteners market, driven by sustained demand from automotive, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of around 5.8% from 2023 to 2028, according to Mordor Intelligence. Within this expansive market, carriage bolts—particularly the widely used 1 ¼-inch variant—remain a critical component in structural assemblies, fencing, and machinery due to their rounded heads and square necks that prevent rotation during installation. With increasing infrastructure investments and the rise of modular construction, demand for high-quality, corrosion-resistant 1 ¼” carriage bolts has intensified. This growing need has elevated the importance of reliable manufacturers who maintain strict quality standards, scalable production, and material innovation. Based on production capacity, geographic reach, compliance with ISO and ASTM standards, and product durability, the following seven manufacturers have emerged as leaders in the 1 ¼” carriage bolt segment.

Top 7 1 4 Carriage Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Carriage Bolts

Domain Est. 1999

Website: fastcoinc.com

Key Highlights: Carriage bolts, or coach bolts, are fasteners used for heavy-duty wood applications. These bolts feature a round head and square neck….

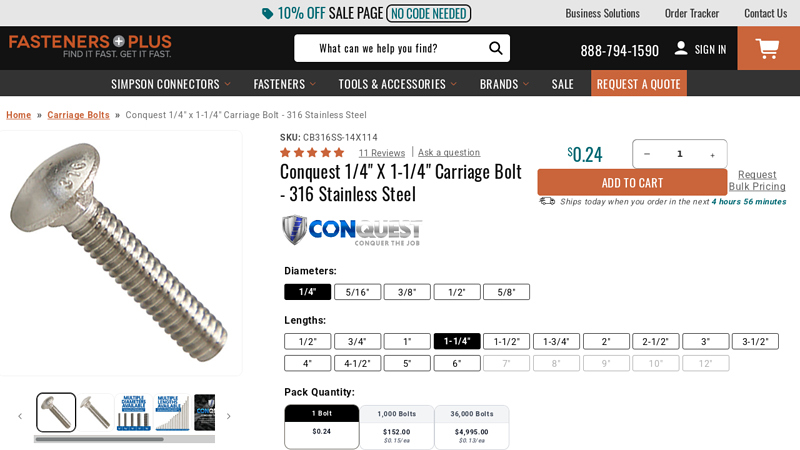

#2 Conquest 1/4″ x 1

Domain Est. 2003

Website: fastenersplus.com

Key Highlights: In stock Rating 5.0 (10) Length: 1-1/4″ ; Material: 316 Stainless Steel ; Head type: Round Head, Square Neck ; Manufacturer name: Conquest Fasteners ; Measuring system: Standard …

#3 1/4″X4

Domain Est. 2012

Website: hewittrad.com

Key Highlights: In stock $27.43 delivery1/4″x4-1/2″ Carriage Bolt. Hewitt is a leading USA manufacturer of docks, lifts, pontoon legs, & much more. Buy online or find a dealer near you!…

#4 Industrial Steel Carriage Bolt Products

Domain Est. 2015

Website: valuefastener.com

Key Highlights: Industrial steel carriage bolt products are manufactured for applications that require a bolt that resists turning when the nut is tightened or removed….

#5 Carriage Bolts

Domain Est. 1996

Website: bacoent.com

Key Highlights: Stainless Steel, Zinc, Galvanized And HDG Bolts Available. Carriage bolts feature a round, domed head and square neck, which is specifically designed to ……

#6 Carriage Bolts

Domain Est. 1997

Website: tannerbolt.com

Key Highlights: Free delivery over $1,249Carriage Bolts, also called round head square neck bolts, generally feature a broad, shallow round head and are inserted into pre-drilled holes….

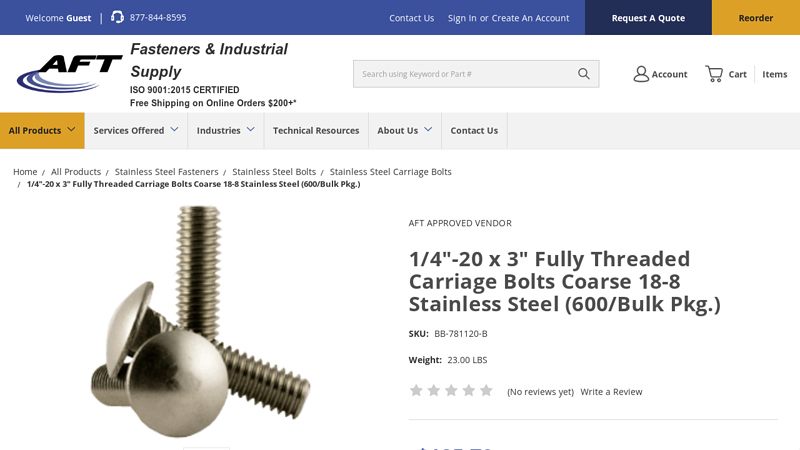

#7 1/4″

Domain Est. 2008

Website: aftfasteners.com

Key Highlights: In stock Free delivery over $200AFT Approved Vendor. 1/4″-20 x 3″ Fully Threaded Carriage Bolts Coarse 18-8 Stainless Steel (600/Bulk Pkg.) SKU: BB-781120-B. Weight: 23.00 LBS….

Expert Sourcing Insights for 1 4 Carriage Bolt

H2: 2026 Market Trends for 1/4-Inch Carriage Bolts

The global market for 1/4-inch carriage bolts is expected to experience steady growth and transformation by 2026, driven by broader construction, manufacturing, and infrastructure development trends. These bolts—recognized for their smooth, domed head and square neck that prevents rotation during installation—are widely used in woodworking, fencing, machinery, and structural applications. Key market dynamics shaping the 2026 outlook include:

-

Increased Infrastructure Investment

Governments worldwide, particularly in North America, Europe, and parts of Asia-Pacific, are prioritizing infrastructure renewal and expansion. Public spending on transportation, utilities, and public buildings is boosting demand for durable fasteners like 1/4-inch carriage bolts. The U.S. Infrastructure Investment and Jobs Act and similar initiatives in Canada and the EU are expected to sustain construction activity, directly benefiting the fastener market. -

Growth in Residential and Commercial Construction

The ongoing recovery and growth in housing markets, especially in emerging economies and suburban developments, are increasing demand for wood and metal framing components. Carriage bolts are commonly used in deck building, timber framing, and fencing—sectors anticipated to remain strong through 2026 due to rising home improvement spending and new construction projects. -

Industrial Automation and Manufacturing Expansion

As manufacturing facilities modernize and expand, especially in automotive, agricultural equipment, and material handling industries, there is continued need for reliable fastening solutions. Carriage bolts are often specified in equipment assembly due to their tamper-resistant design and durability. Growth in automation and reshoring of manufacturing in the U.S. and Europe will support demand. -

Material and Sustainability Trends

The fastener industry is seeing increased focus on corrosion resistance and sustainability. By 2026, demand for 1/4-inch carriage bolts made from hot-dipped galvanized steel, stainless steel, or with eco-friendly coatings is expected to rise. Manufacturers are also exploring recyclable materials and energy-efficient production methods to meet environmental regulations and buyer preferences. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted companies to diversify sourcing and shorten supply chains. This trend is encouraging regional production of fasteners, including carriage bolts, reducing dependency on imports. By 2026, localized manufacturing hubs in North America and Europe may capture increased market share, improving lead times and reducing costs. -

E-commerce and Distribution Channels

Online procurement of industrial supplies continues to grow. Platforms like Amazon Business, Fastenal, and Grainger are making it easier for contractors and DIY users to access standardized fasteners such as 1/4-inch carriage bolts. This shift enhances market reach and transparency, pushing suppliers to improve packaging, labeling, and inventory management. -

Price Volatility and Raw Material Costs

Steel prices, influenced by global trade policies, energy costs, and geopolitical factors, remain a key risk. Fluctuations in iron ore and scrap metal prices could impact the cost of 1/4-inch carriage bolts. However, economies of scale and improved production efficiency may help mitigate some cost pressures by 2026.

In summary, the 1/4-inch carriage bolt market in 2026 will be shaped by strong end-user demand from construction and manufacturing, coupled with evolving material standards and supply chain strategies. While competition and cost management will remain challenges, the overall outlook remains positive, with steady demand forecast across key industrial and residential sectors.

Common Pitfalls Sourcing 1/4 Inch Carriage Bolts (Quality, IP)

Sourcing 1/4 inch carriage bolts—especially with attention to quality and IP (Ingress Protection) ratings—can present several challenges, particularly when intended for outdoor, industrial, or high-stress applications. Below are common pitfalls to watch for:

Inadequate Material Quality

Many suppliers offer carriage bolts made from low-grade steel or unverified alloys. Without proper certification (e.g., ASTM A307 or ISO 898-1), bolts may lack the required tensile strength or durability. Always verify material specifications and request test reports when high performance is critical.

Misunderstanding IP Ratings

Carriage bolts themselves are not typically assigned IP ratings, as these apply to enclosures, not fasteners. However, confusion arises when sourcing bolts for use in IP-rated assemblies (e.g., electrical enclosures). Using non-corrosion-resistant bolts can compromise the overall IP rating by allowing rust or degradation that creates gaps. Ensure compatibility with the environmental protection goals of the final product.

Incorrect Thread or Shank Dimensions

Tolerance variations in thread pitch, diameter, or square neck size can lead to poor fit or installation issues. Especially with metric vs. imperial specifications, even a slight deviation in the 1/4 inch diameter or thread count (e.g., 1/4″-20 vs. 1/4″-28) can result in assembly failures.

Poor Corrosion Resistance

For outdoor or humid environments, lack of proper plating (e.g., zinc, hot-dip galvanized, or stainless steel) leads to premature rusting. Avoid generic “weather-resistant” claims without knowing the actual coating thickness or type (e.g., ASTM F1941 for mechanical plating).

Counterfeit or Non-Compliant Products

Imported bolts may lack traceability, proper markings, or compliance with regional standards (e.g., CE, RoHS). This is especially risky when sourcing from low-cost overseas suppliers without audits or quality control.

Inconsistent Head or Square Neck Design

The square neck beneath the head must properly resist rotation during installation. Poorly formed or undersized square sections can spin in the receiving material, compromising joint integrity.

Overlooking Application-Specific Standards

Certain industries (marine, automotive, structural) have specific requirements for fasteners. Using standard-duty carriage bolts in high-vibration or load-bearing scenarios without verifying suitability can lead to failure.

To mitigate these pitfalls, always source from reputable suppliers, request material certifications, clarify environmental requirements, and ensure dimensional and performance standards align with your application needs.

Logistics & Compliance Guide for 1/4″ Carriage Bolt

This guide outlines key logistics and compliance considerations for handling, transporting, storing, and using 1/4″ carriage bolts, ensuring operational efficiency and adherence to regulatory standards.

Product Specifications & Identification

- Nominal Size: 1/4 inch diameter

- Thread Length: Varies by bolt length (e.g., 3/4″, 1″, 1-1/2″, etc.)

- Head Type: Domed (round) head with a square neck beneath to prevent rotation during installation

- Material: Typically steel (plain, zinc-plated, or hot-dip galvanized); stainless steel or other alloys may be used depending on application

- Standards: Complies with ASME B18.5 for carriage bolts; may meet ASTM A307 Grade A (general purpose) or other specifications depending on grade

- Finish: Common finishes include plain (unfinished), zinc-plated (clear or yellow chromate), or hot-dip galvanized for corrosion resistance

Packaging & Labeling Requirements

- Primary Packaging: Bulk packed in poly bags, shrink-wrapped bundles, or corrugated boxes; smaller quantities may be in retail clamshells or blister packs

- Secondary Packaging: Packed in master cartons labeled with:

- Product description (e.g., “1/4” Carriage Bolt, Zinc Plated, 2” Long”)

- Quantity per box

- Part/Stock Number (SKU)

- Manufacturer or supplier name

- Lot or batch number (for traceability)

- Compliance markings (e.g., RoHS, REACH if applicable)

- Barcoding: UPC or QR codes for inventory and supply chain tracking

- Hazard Labeling: Generally not required for standard steel carriage bolts unless coated with hazardous substances (verify SDS)

Transportation & Handling

- Mode of Transport: Suitable for all standard modes (truck, rail, air, sea) when properly packaged

- Load Securing: Palletized loads must be stretch-wrapped and banded; unit loads should be stable to prevent shifting

- Handling Precautions:

- Use appropriate lifting equipment for heavy pallets

- Avoid dropping or impact to prevent deformation

- Use gloves to prevent hand injuries from sharp edges

- Environmental Protection: Protect from moisture during transit to prevent rust, especially for non-galvanized bolts

Storage Conditions

- Environment: Store indoors in a dry, well-ventilated area

- Temperature: Ambient conditions (40°F to 90°F / 5°C to 32°C recommended)

- Humidity: Keep relative humidity below 60% to minimize corrosion risk

- Shelving: Use pallet racking or shelves; avoid direct floor contact

- Segregation: Store away from corrosive chemicals, salts, and moisture sources

- First-In, First-Out (FIFO): Implement inventory rotation to prevent long-term storage issues

Regulatory & Compliance Standards

- U.S. Regulations:

- ITAR/EAR: Not typically controlled unless used in defense or aerospace applications

- CPSC: Not applicable for industrial fasteners

- DOT: No special handling requirements for standard steel bolts

- International:

- REACH (EU): Ensure no SVHCs (Substances of Very High Concern) above threshold in plating or coatings

- RoHS (EU): Applies if bolts are used in electrical/electronic equipment; confirm plating complies

- Customs Classification: HS Code typically 7318.15 (screws, bolts, and nuts, of iron or steel)

- Safety Data Sheet (SDS): Required under OSHA HazCom if coatings contain hazardous substances (e.g., hexavalent chromium in some platings); otherwise, may be exempt

Quality Assurance & Traceability

- Incoming Inspection: Verify dimensions, thread accuracy, finish, and packaging per purchase order

- Certifications: Request mill test reports (MTRs) or certs of compliance for critical applications

- Traceability: Maintain lot/batch records for recall or quality investigations

- Non-Conformance Handling: Quarantine and report defective shipments per supplier agreement

Environmental & Sustainability Considerations

- Recyclability: 100% recyclable as ferrous metal; encourage recycling of packaging materials

- Waste Disposal: Dispose of metal waste via scrap metal recyclers; follow local regulations for coated bolts

- Sustainable Sourcing: Prefer suppliers with ISO 14001 certification or environmental management systems

Summary

Proper logistics and compliance management for 1/4″ carriage bolts ensures product integrity, regulatory adherence, and supply chain efficiency. Attention to packaging, storage, transportation, and documentation supports safe handling and traceability across industrial and commercial applications. Always verify specific requirements based on end-use and geographic market.

In conclusion, sourcing 1/4-inch carriage bolts requires careful consideration of factors such as material type, grade, length, finish, quantity, and supplier reliability. Whether for construction, woodworking, or industrial applications, ensuring the bolts meet required specifications (e.g., ASTM standards) is essential for safety and performance. Exploring local hardware stores, online retailers, or industrial suppliers can provide convenient access, while comparing pricing and lead times helps optimize cost-efficiency. By verifying quality and compliance, you can confidently source 1/4-inch carriage bolts that meet your project’s needs.