The global fastener market, driven by robust demand from automotive, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. Within this expansive industry, carriage bolts—a critical fastener known for their rounded heads and square necks that prevent rotation during installation—remain in consistent demand for applications in machinery, fencing, and structural assembly. With an estimated valuation exceeding USD 110 billion in 2023 (Grand View Research), the fastener market’s expansion underscores the growing need for high-quality, reliable bolt manufacturing. As industries prioritize durability and standardization, sourcing from reputable carriage bolt manufacturers has become increasingly vital. The following list highlights the top 10 manufacturers excelling in product quality, production capacity, global reach, and compliance with international standards, positioning them at the forefront of a steadily growing segment.

Top 10 1 2 Carriage Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Carriage Bolts

Domain Est. 1999

Website: fastcoinc.com

Key Highlights: Carriage bolts, or coach bolts, are fasteners used for heavy-duty wood applications. These bolts feature a round head and square neck….

#2 1/2″X4″ Stainless Carriage Bolt

Domain Est. 2012

Website: hewittrad.com

Key Highlights: In stock $27.43 delivery1/2″x4″ Stainless Carriage Bolt. Hewitt is a leading USA manufacturer of docks, lifts, pontoon legs, & much more. Buy online or find a dealer near you!…

#3 Carriage Bolts

Domain Est. 1996

Website: bacoent.com

Key Highlights: When you need stainless, HDG (hot dipped galvanized), zinc carriage bolts or other types, Baco Enterprises can offer competitive prices and unmatched ……

#4 Carriage Bolts

Domain Est. 1997

Website: tannerbolt.com

Key Highlights: Free delivery over $1,249Carriage Bolts, also called round head square neck bolts, generally feature a broad, shallow round head and are inserted into pre-drilled holes….

#5 Carriage Bolts

Domain Est. 1999

Website: uboltit.com

Key Highlights: U-Bolt-It manufactures Carriage Bolts which have a round head and square neck that prevents the bolt from turning when the nut is tightened. Carriage bolts ……

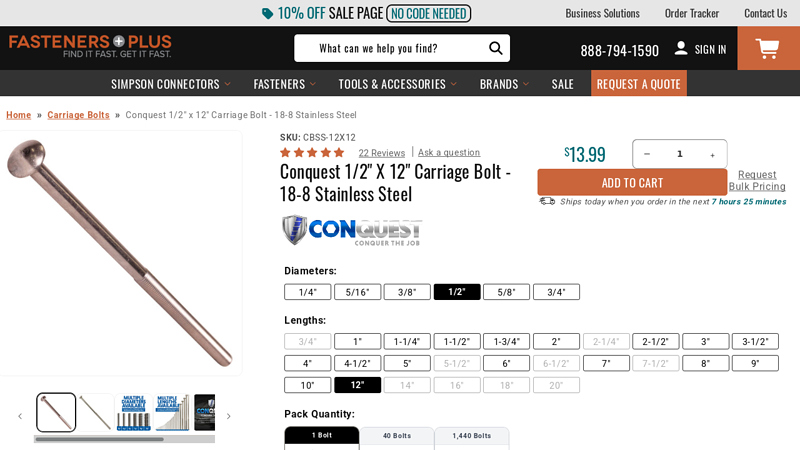

#6 Conquest 1/2″ x 12″ Carriage Bolt

Domain Est. 2003

Website: fastenersplus.com

Key Highlights: Built for professionals and serious DIYers, this stainless steel carriage bolt delivers the durability and performance needed for demanding jobs….

#7 Carriage Bolts

Domain Est. 2003

Website: americanboltcorp.com

Key Highlights: Shop carriage bolts in A307, Grade 5, Grade 8 & stainless. Round head, square neck prevents spinning—ideal for wood-to-wood and ……

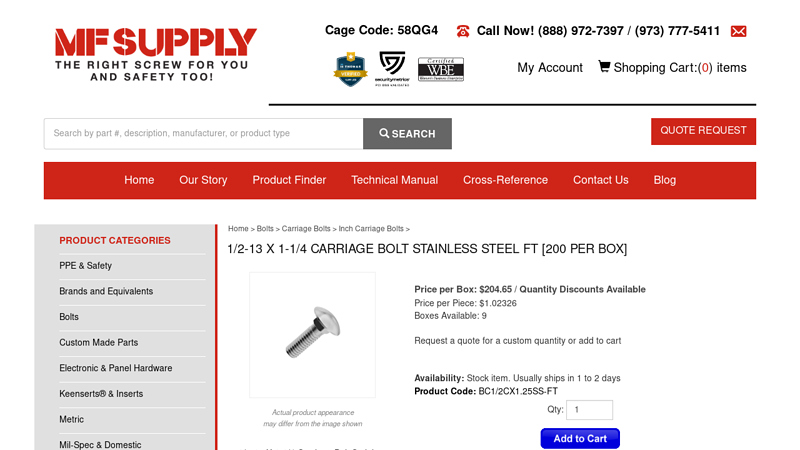

#8 1/2-13 X 1-1/4 Carriage Bolt Stainless Steel FT

Domain Est. 2004

Website: mfsupply.com

Key Highlights: MF Supply is a leading supplier of 1/2-13 X 1-1/4 Carriage Bolt 18-8 Stainless Steel Full Thread. Buy online or request a custom quote today!…

#9 part #9113

Domain Est. 2005

Website: bairproducts.com

Key Highlights: PART #9113 – 1/2″ CARRIAGE BOLT AND NUT. Your Price: $2.00. Part Number: #9113. Availability: In Stock….

#10 Carriage Bolts

Domain Est. 2018

Website: patriotbolt.com

Key Highlights: Carriage bolts come in a wide range of sizes, typically from 1/2 inch to 10 inches long and from 3/16 to 3/4 inch in diameter, allowing for varied applications….

Expert Sourcing Insights for 1 2 Carriage Bolt

H2: Projected 2026 Market Trends for 1/2 Inch Carriage Bolts

The global market for 1/2 inch carriage bolts is expected to experience steady growth and notable shifts by 2026, driven by evolving industrial demands, construction activity, and supply chain dynamics. Key trends shaping the market include:

1. Rising Construction and Infrastructure Development

Anticipated government investments in infrastructure across North America, Europe, and parts of Asia-Pacific are expected to drive demand for durable fasteners like 1/2 inch carriage bolts. These bolts are commonly used in structural framing, fencing, and timber construction due to their rounded heads and square necks that prevent rotation. Increased residential and commercial building projects will support market expansion through 2026.

2. Growth in Industrial Manufacturing and DIY Markets

The continued expansion of light to medium industrial manufacturing, particularly in machinery assembly and agricultural equipment, will sustain demand. Additionally, the growing do-it-yourself (DIY) home improvement trend—amplified by online tutorials and retail availability—will boost consumer-level purchases of standardized fasteners, including 1/2 inch carriage bolts.

3. Material and Coating Innovations

By 2026, there will be a stronger market preference for corrosion-resistant materials such as hot-dip galvanized steel, stainless steel, and zinc-coated variants. Environmental regulations and durability requirements in outdoor and marine applications are pushing manufacturers to adopt advanced coatings, enhancing product lifespan and opening premium pricing segments.

4. Supply Chain Optimization and Localization

Post-pandemic supply chain reconfigurations are leading to a regionalization of fastener manufacturing. Companies are increasingly investing in localized production to reduce lead times and mitigate trade disruptions. This trend is expected to improve availability and responsiveness in key markets like the U.S. and Germany.

5. E-commerce and Digital Distribution Channels

Online platforms—both B2B (e.g., Fastenal, Grainger) and B2C (e.g., Amazon, Home Depot online)—are becoming primary distribution channels. By 2026, digital procurement is projected to account for over 40% of fastener sales, enabling faster delivery, competitive pricing, and broader market reach, especially for standard sizes like 1/2 inch carriage bolts.

6. Sustainability and Regulatory Pressures

Environmental standards, such as REACH and RoHS compliance, are influencing material sourcing and production practices. Manufacturers are adopting leaner processes and recyclable materials to meet sustainability goals, which could affect pricing and production strategies.

In summary, the 1/2 inch carriage bolt market in 2026 will be characterized by steady demand from construction and industrial sectors, enhanced product offerings through material innovation, and a transformation in how products are distributed and purchased—positioning the market for moderate but resilient growth.

H2: Common Pitfalls When Sourcing 1/2-Inch Carriage Bolts (Quality and IP Considerations)

Sourcing 1/2-inch carriage bolts may seem straightforward, but several common pitfalls—particularly related to quality and Intellectual Property (IP)—can lead to supply chain disruptions, safety issues, or legal risks. Understanding these challenges helps ensure reliable procurement and compliance.

1. Inconsistent Material Quality and Grade

One of the most frequent issues is receiving bolts made from substandard materials. Carriage bolts should meet recognized standards such as ASTM A307 or Grade 2/Grade 5 specifications. Sourcing from unreliable suppliers may result in bolts that are undersized, improperly heat-treated, or made from low-grade steel, compromising structural integrity.

2. Lack of Certification and Traceability

Reputable suppliers provide mill test reports or certificates of conformance (CoC) verifying material composition and mechanical properties. Without these, it’s difficult to confirm compliance with industry standards—especially critical in construction, infrastructure, or safety-critical applications.

3. Misrepresentation of IP and Branding

Some suppliers may falsely claim that their bolts are manufactured under license or meet proprietary specifications. Unauthorized use of patented designs (e.g., unique head profiles or locking mechanisms) can expose buyers to IP infringement claims. Always verify whether the product design or manufacturing process is protected.

4. Counterfeit or Non-Compliant Fasteners

The global market is plagued by counterfeit fasteners that mimic reputable brands or standards. These may bear fake markings (e.g., forged ASTM or ISO labels) but fail performance tests. Sourcing from unverified vendors increases the risk of receiving non-compliant 1/2-inch carriage bolts.

5. Inadequate Corrosion Resistance

Carriage bolts used in outdoor or high-moisture environments require proper plating or coating (e.g., zinc, hot-dip galvanized, or stainless steel). Some suppliers may misrepresent coating thickness or type, leading to premature rust and failure. Ensure the product meets required environmental standards (e.g., ASTM B633).

6. Poor Dimensional Accuracy

Even slight deviations in bolt length, shank diameter, or head size can prevent proper fit or installation. Low-cost manufacturers may cut corners on machining precision, especially with the square neck feature designed to prevent rotation. Always request dimensional inspection reports when sourcing in bulk.

7. Ignoring Regional Standards and Regulations

Different markets have specific fastener regulations (e.g., CE marking in Europe, ASME/ANSI in North America). Sourcing bolts without confirming regional compliance can result in rejected shipments or legal liability. This is especially important when importing 1/2-inch carriage bolts for certified projects.

8. Overlooking Supplier Due Diligence

Failing to audit or vet suppliers—especially overseas manufacturers—increases exposure to quality and IP risks. Conduct site visits, review certifications, and assess manufacturing capabilities before committing to large orders.

By addressing these pitfalls proactively, procurement teams can ensure they source high-quality, compliant, and legally sound 1/2-inch carriage bolts, minimizing risk across projects and supply chains.

Logistics & Compliance Guide for 1/2″ Carriage Bolt

This guide outlines the key logistics and compliance considerations for handling, transporting, and using 1/2″ carriage bolts in industrial, construction, or distribution environments. Proper management ensures safety, regulatory adherence, and supply chain efficiency.

Product Specifications and Identification

A 1/2″ carriage bolt features a domed head and a square neck beneath the head, designed to prevent rotation when inserted into a square hole. Key specifications include:

– Diameter: 1/2 inch (nominal)

– Thread Length: Varies by application (e.g., 1″, 1.5″, 2″)

– Overall Length: Measured from underside of head to end of shank

– Material: Typically ASTM A307 Grade A (carbon steel), may be hot-dip galvanized or zinc-plated

– Standards Compliance: Meets ASME B18.5 for dimensions and mechanical properties

Ensure exact specifications are verified per purchase order and product datasheet to avoid substitution errors.

Packaging and Handling Requirements

Proper packaging ensures product integrity and facilitates efficient logistics:

- Unit Packaging: Bolts are commonly packed in labeled plastic bags, cardboard boxes, or shrink-wrapped bundles.

- Bulk Packaging: For large volumes, use palletized crates or steel/wooden bins. Max pallet load: 2,000 lbs unless otherwise rated.

- Labeling: Each unit must display:

- Product description (e.g., “1/2″ x 2″ Carriage Bolt, ASTM A307”)

- Quantity

- Lot or batch number

- Manufacturer or supplier ID

- Handling symbols (e.g., “Fragile,” “This Side Up”)

- Handling: Use mechanical aids (forklifts, pallet jacks) for pallets. Avoid dragging or dropping containers to prevent damage and worker injury.

Storage Conditions

Optimal storage preserves material quality and prevents corrosion:

- Environment: Store indoors in a dry, temperature-controlled area (40°F–90°F / 5°C–32°C), away from direct sunlight and moisture.

- Humidity: Relative humidity below 60% to minimize rust risk.

- Ventilation: Ensure adequate airflow to prevent condensation.

- Racking: Keep packages off the floor (minimum 6 inches) using pallets or shelving. Segregate by grade, finish, and size.

- Shelf Life: Indefinite if stored properly. Inspect periodically for signs of corrosion or packaging damage.

Transportation and Shipping

Follow best practices for safe and compliant shipment:

- Mode Selection: Suitable for truck, rail, air, or sea freight depending on volume and urgency.

- Palletization: Secure loads with stretch wrap and edge protectors. Use banding or strapping for stability.

- Documentation: Include:

- Commercial Invoice

- Packing List

- Bill of Lading

- Material Safety Data Sheet (MSDS/SDS) – although non-hazardous, may be required for customs

- Hazard Classification: 1/2″ carriage bolts are non-hazardous under DOT, IATA, and IMDG regulations.

- Export Controls: Generally not subject to ITAR or EAR restrictions, but verify for high-strength alloys or special finishes.

Regulatory and Compliance Standards

Adherence to industry and safety standards is mandatory:

- ASTM A307: Standard specification for carbon steel bolts and studs.

- ASME B18.5: Dimensional standards for carriage bolts.

- OSHA 1910.132: Personal protective equipment (PPE) required during handling (e.g., gloves, safety glasses).

- REACH & RoHS: Compliance required if selling in the EU. Confirm plating materials (e.g., hexavalent chromium-free zinc) meet regulations.

- Customs Tariff Code (HTS): 7318.15.00 – Bolts and bolts and bolts, of iron or steel. Verify local tariff codes for import/export.

Quality Assurance and Traceability

Maintain full supply chain transparency:

- Inspection: Perform incoming and outgoing visual and dimensional checks.

- Certifications: Request mill test reports (MTRs) or certificates of conformance (CoC) from suppliers.

- Traceability: Retain lot numbers and supplier documentation for minimum 5 years (or per company policy).

- Non-Conformance: Isolate and quarantine defective batches. Report to supplier and document corrective actions.

Environmental and Safety Considerations

- Waste Disposal: Scrap metal is recyclable. Dispose of packaging per local regulations (e.g., cardboard recycling, plastic reclamation).

- Worker Safety: Provide training on manual handling to prevent strains. Use PPE to avoid cuts from sharp edges.

- Spill/Leak Response: Not applicable for solid bolts, but galvanizing residues (e.g., zinc dust) should be cleaned with damp cloths and disposed of as metal-contaminated waste if present.

Summary

The logistics and compliance framework for 1/2″ carriage bolts emphasizes proper identification, packaging, storage, and documentation. While not classified as hazardous, adherence to ASTM, ASME, OSHA, and environmental regulations ensures safe handling and legal distribution. Maintain traceability and quality control to support supply chain integrity and customer confidence.

Conclusion for Sourcing 1/2 Inch Carriage Bolt:

After evaluating various suppliers, material specifications, and cost considerations, sourcing a 1/2 inch carriage bolt is a straightforward process given its standardized nature and widespread availability. These bolts, commonly used in structural and outdoor applications due to their smooth, domed head and square neck that prevents spinning during installation, can be procured from industrial hardware suppliers, online marketplaces, or local hardware stores.

Key considerations when sourcing include determining the required length, thread type (typically UNC), material (such as zinc-plated steel, stainless steel, or hot-dipped galvanized for corrosion resistance), and compliance with industry standards (e.g., ASTM A307 or ASME B18.5). Bulk purchasing from reputable suppliers often results in cost savings without compromising quality.

In conclusion, the 1/2 inch carriage bolt is readily available, cost-effective, and essential for many construction and assembly applications. Ensuring proper specifications and supplier reliability will lead to optimal performance and durability in the intended use.