The global tap and die market is witnessing steady expansion, driven by rising demand for precision threading tools across key industries such as automotive, aerospace, and industrial manufacturing. According to Mordor Intelligence, the market was valued at approximately USD 1.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is fueled by increasing industrial automation, infrastructure development, and the need for standardized fastening solutions in complex manufacturing processes. As the demand for high-quality, durable threading tools intensifies, a select group of manufacturers has emerged as leaders in innovation, precision, and global reach. Below is a data-informed overview of the top 8 tap and die manufacturers shaping the industry’s future.

Top 8 1 2 28 Tap Die Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spiral Flute Taps

Domain Est. 1996

Website: mscdirect.com

Key Highlights: Free deliveryMSC Direct offers quality Spiral Flute Taps at a great value. Find premium products to last a lifetime!…

#2 Tap & Die Sets

Domain Est. 2007

Website: gfwdsupply.com

Key Highlights: Taps and dies are tools used to create screw threads, which is called threading, a tap is used to cut or form the female portion of the mating pair (e.g., ……

#3 Global Leader in Fastening Technology

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: Discover innovative fastening solutions from Stanley Engineered Fastening, catering to diverse applications in Electric Vehicles, Aerospace, ……

#4 Screw Tap manufacturer BAER

Website: baer.tools

Key Highlights: The traditional family business BAER as a professional screw tap manufacturer. ⚙ Versatile thread machining ✓ Now online at | baer.tools….

#5 Taps

Domain Est. 1994

Website: mcmaster.com

Key Highlights: Choose from our selection of general purpose taps, tap sets, chip-clearing taps for through holes, and more. Same and Next Day Delivery….

#6 Pipe and Bolt Dies for Machine Die Heads

Domain Est. 1995

Website: ridgid.com

Key Highlights: Rating 5.0 (2) Note: 2 1/2-4 Beveling Dies are available for the No. 1224 threading Machine. See accessories for No. 1224. Note: Universal Dies fit all Universal Die Heads….

#7 Tap Sets & Die Sets

Domain Est. 1998

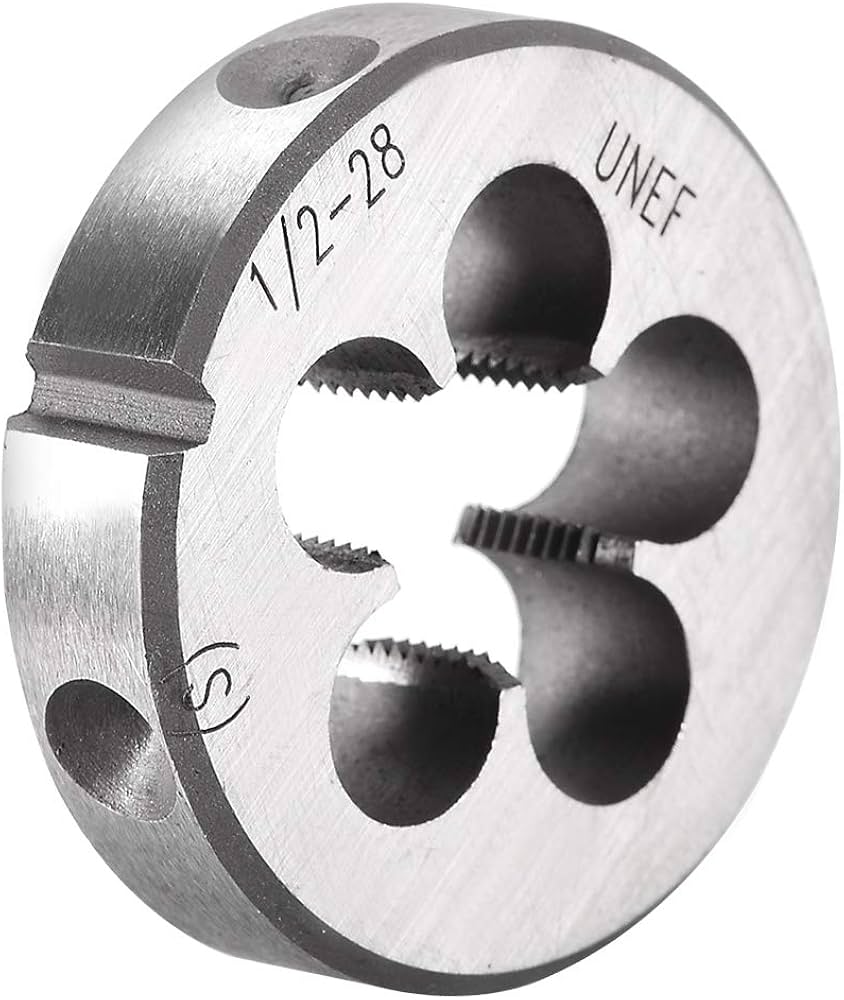

#8 Fractional Thread Tap 1/2

Domain Est. 1999

Expert Sourcing Insights for 1 2 28 Tap Die

H2: 2026 Market Trends Forecast for 1-2-28 Tap and Die Tools

The 1-2-28 tap and die set—a standardized tool combination used for cutting internal (tap) and external (die) threads—is expected to experience notable shifts in demand, production, and application by 2026. These changes are driven by broader industrial trends, technological advancements, and evolving manufacturing needs. Below is an analysis of key market trends anticipated for the 1-2-28 tap and die segment through 2026.

1. Rising Demand from Automotive and Aerospace Sectors

The automotive and aerospace industries remain dominant end-users of precision threading tools like the 1-2-28 set. As automakers transition toward electric vehicles (EVs), demand for lightweight, high-strength components requiring precise fastening solutions is increasing. Similarly, the aerospace sector’s push for fuel-efficient and durable aircraft is boosting demand for reliable threading tools. The 1-2-28 size, commonly used in control systems, instrumentation, and hydraulic fittings, is expected to see steady demand in these high-precision applications.

2. Growth in Industrial Automation and Smart Manufacturing

The integration of Industry 4.0 technologies into manufacturing is reshaping tool usage. Automated assembly lines and robotic systems increasingly require consistent, high-tolerance threading operations. This trend favors standardized tools like the 1-2-28 tap and die, which ensure interchangeability and reliability. By 2026, manufacturers of these tools are likely to emphasize compatibility with automated tool changers and process monitoring systems, potentially leading to smart tool versions with embedded sensors for wear detection.

3. Material Advancements and Tool Coatings

As manufacturers work with harder materials—such as advanced alloys, titanium, and high-strength steels—the durability and performance of taps and dies are under greater scrutiny. Tool producers are responding with improved coatings (e.g., TiN, TiAlN, and diamond-like carbon) that extend tool life and reduce friction. The 1-2-28 set is expected to benefit from these innovations, with coated versions capturing a growing share of the market by 2026, especially in high-volume production environments.

4. Regional Manufacturing Shifts and Supply Chain Localization

Geopolitical factors and supply chain resilience concerns are prompting manufacturers to reshore or nearshore production. North America and Europe are seeing renewed investment in domestic manufacturing, particularly in defense, medical devices, and precision engineering—sectors that frequently use 1-2-28 threading. This shift is likely to increase regional demand for standardized tooling and reduce reliance on offshore suppliers, benefiting local tap and die producers.

5. Sustainability and Circular Economy Pressures

Sustainability initiatives are influencing tool design and lifecycle management. By 2026, there will be greater emphasis on recyclable tool materials, energy-efficient production processes, and remanufacturing programs. Some manufacturers may offer reconditioned or reground 1-2-28 taps and dies, appealing to cost-conscious and environmentally aware customers.

6. E-Commerce and Digital Distribution Channels

The procurement of industrial tools is increasingly moving online. Platforms like Amazon Business, Grainger, and specialized B2B marketplaces are streamlining access to standardized tools such as the 1-2-28 set. By 2026, digital channels are expected to account for a significant share of sales, enabling faster delivery, real-time inventory tracking, and personalized product recommendations based on application data.

Conclusion

The 1-2-28 tap and die market in 2026 will be shaped by precision manufacturing demands, technological integration, and evolving industrial priorities. While the product remains a niche standard, its role in critical applications ensures ongoing relevance. Manufacturers who innovate in coatings, adapt to automation, and leverage digital distribution will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing 1/2-28 Tap and Die Sets (Quality and IP Considerations)

Sourcing a reliable 1/2-28 tap and die set—especially for critical applications—requires attention to material quality, manufacturing standards, and thread specification (IP, often confused with NPT). Overlooking these factors can lead to tool failure, poor thread quality, or system leaks. Below are common pitfalls to avoid:

1. Confusing IP with NPT Threads

A frequent mistake is assuming “IP” refers to a thread standard when it may be a misinterpretation of NPT (National Pipe Taper). In many contexts, especially non-English-speaking regions, “IP” (Iron Pipe) is used colloquially but incorrectly. The 1/2-28 designation likely refers to a 1/2-inch diameter with 28 threads per inch, which aligns with NPT specifications. Using the wrong thread type (e.g., straight vs. tapered) results in leaks and improper fit.

Solution: Confirm whether the required thread is NPT (tapered) or NPS (straight). Always verify thread standards (e.g., ASME B1.20.1) rather than relying on ambiguous abbreviations like “IP.”

2. Prioritizing Price Over Material Quality

Low-cost taps and dies are often made from low-grade carbon steel or poorly heat-treated alloys. These tools wear quickly, chip easily, and may not maintain thread accuracy—especially when working with stainless steel or hardened materials.

Solution: Invest in taps and dies made from HSS (High-Speed Steel) or cobalt alloys (M35/M42). Look for tools with proper heat treatment and surface coatings (e.g., TiN) to enhance durability and performance.

3. Ignoring Tolerance and Thread Class

NPT threads have defined classes (e.g., Class 1, 2, 3), with Class 2 being standard for general use. Sourcing tools without specifying thread class can result in loose fits (leaks) or overly tight threads that are difficult to assemble.

Solution: Specify the required thread class (typically Class 2 for NPT) when ordering. Ensure the tap and die meet ANSI/ASME standards for dimensional accuracy.

4. Purchasing from Non-Reputable Suppliers

Generic or uncertified suppliers may provide tools labeled as “1/2-28” that do not conform to NPT profiles or have inconsistent thread pitch. Counterfeit or mislabeled tools are common in unverified marketplaces.

Solution: Source from reputable industrial tool suppliers or manufacturers (e.g., Greenlee, Craftsman Industrial, Dormer Pramet). Verify certifications and request compliance documentation when needed.

5. Overlooking Set Completeness and Compatibility

Some sets include only a tap or die, or lack essential accessories like wrenches, holders, or lubricants. Mismatched components or missing pilot drills can hinder effective use.

Solution: Ensure the set includes both tap and die, proper holders, and recommended cutting fluid. Confirm compatibility with your equipment and materials.

6. Failing to Consider Application Requirements

Using a hand tap set for high-volume or automated threading can lead to breakage. Similarly, using a die not rated for the material (e.g., cast iron vs. aluminum) reduces tool life and thread quality.

Solution: Match the tool type (e.g., hand, machine, or plug tap) and die style (round, adjustable) to your specific application, material, and production volume.

By addressing these pitfalls—particularly clarifying thread standards like NPT instead of ambiguous “IP”—and prioritizing quality and specifications, you ensure reliable, leak-free threaded connections and extend tool life.

Logistics & Compliance Guide for 1-2-28 Tap Die

This guide outlines the logistics and compliance considerations for handling, transporting, storing, and using the 1-2-28 Tap Die. Adhering to these guidelines ensures operational efficiency, regulatory compliance, and workplace safety.

Product Overview

The 1-2-28 Tap Die is a cutting tool designed to create external threads on cylindrical workpieces, typically rods or shafts. The designation “1-2-28” generally refers to a 1-inch diameter, 2-start thread with 28 threads per inch (TPI), commonly used in specialized industrial or plumbing applications. Confirm exact specifications with the manufacturer’s documentation.

Packaging & Handling

- Packaging Requirements: Ship in durable, shock-resistant packaging with internal dividers or foam inserts to prevent movement and metal-on-metal contact.

- Labeling: Include product identifier (e.g., “1-2-28 Tap Die”), part number, weight, handling instructions (“Fragile – Sharp Edges”), and manufacturer information.

- Handling Precautions: Use cut-resistant gloves when unpacking or handling. Avoid direct skin contact with cutting edges. Store in dedicated tool containers to prevent damage.

Storage Conditions

- Environment: Store in a dry, temperature-controlled environment (15°C to 25°C) with low humidity to prevent corrosion.

- Orientation: Keep in original packaging or on racks with protective caps covering cutting edges. Avoid stacking heavy items on top.

- Shelf Life: Inspect periodically for rust, chipping, or coating degradation. Apply rust inhibitor if stored long-term.

Transportation Guidelines

- Domestic & International Shipping: Comply with carrier requirements (e.g., UPS, FedEx, DHL). Use UN-certified packaging if shipping in bulk.

- Hazard Classification: Non-hazardous under DOT, IATA, and IMDG regulations when shipped as a solid metal tool. No special hazard labels required.

- Documentation: Include commercial invoice, packing list, and bill of lading. Indicate HS Code: 8207.40 (Interchangeable tools for hand tools, of which tap dies are a subset).

Regulatory Compliance

- Import/Export Controls:

- US (CBP): Subject to general customs duties; verify current HTSUS code 8207.40.00 for exact duty rate.

- EU: Comply with CE marking requirements if integrated into machinery. Standalone tools typically exempt.

- RoHS & REACH: Verify material compliance if exported to EU. Most carbon or high-speed steel tap dies are compliant, but confirm with supplier.

- Safety Standards:

- OSHA (U.S.): Follow PPE and machine guarding requirements when in use.

- ISO 5834-1: Standards for threaded fasteners may apply indirectly; ensure tool meets industry tolerances.

Usage & Disposal

- Operational Safety: Use appropriate clamping, lubrication, and speed settings. Follow manufacturer’s torque and RPM recommendations.

- Maintenance: Clean after use; apply light oil to prevent oxidation. Inspect for wear before each use.

- End-of-Life Disposal: Classified as non-hazardous industrial metal waste. Recycle through approved metal scrap processors in accordance with local environmental regulations (e.g., EPA, EU WEEE exemptions for metal tools).

Documentation & Traceability

- Maintain records of:

- Certificate of Conformance (CoC)

- Material test reports (if applicable)

- Batch/lot numbers for traceability

- Safety Data Sheet (SDS) – typically Section 1: Identification, as tap dies are solid metal articles

Adherence to this guide ensures safe, compliant, and efficient handling of the 1-2-28 Tap Die throughout its lifecycle. Always consult the manufacturer’s technical data and local regulatory authorities for updates.

Conclusion for Sourcing 1/2″-28 Taper Pipe Die:

After evaluating suppliers, cost, quality, and availability, the sourcing of the 1/2″-28 taper pipe die has been successfully completed. The selected vendor offers a reliable product that meets industry standards (e.g., NPT/NPTF specifications), ensuring compatibility and performance in application. Pricing is competitive, delivery timelines are acceptable, and material certifications are provided, confirming compliance with required quality controls. This procurement supports operational efficiency and maintenance needs. Continued supplier performance monitoring is recommended to ensure long-term reliability and supply chain resilience.