The global market for automotive wiring, including specialized gauge wires such as 9 AWG, is experiencing steady expansion driven by rising vehicle production, increased electrification in transportation, and growing demand for high-performance electrical systems. According to Grand View Research, the global automotive wiring harness market was valued at USD 44.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth trajectory reflects heightened requirements for reliable, durable, and efficient wiring solutions across automotive, marine, and industrial applications—segments where 9 AWG wire plays a critical role due to its optimal balance of current-carrying capacity and flexibility. As demand for robust electrical infrastructure intensifies, manufacturers of 9 AWG wire are scaling innovation in materials, conductivity, and compliance to meet stringent industry standards. The following list highlights the top nine manufacturers leading this space through consistent quality, technological advancement, and global supply capabilities.

Top 9 0 Awg Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire and Cable Manufacturers

Domain Est. 1996

Website: encorewire.com

Key Highlights: Encore Wire is the leading manufacturer of copper and aluminum for residential, commercial and industrial wire needs. We’re unlike any other wire company….

#2 AmerCable Power, Control and Instrumentation Cables

Domain Est. 1995

Website: amercable.com

Key Highlights: AmerCable is a customer-focused, ISO 9001:2015-certified manufacturer of jacketed electrical power, control and instrumentation cables….

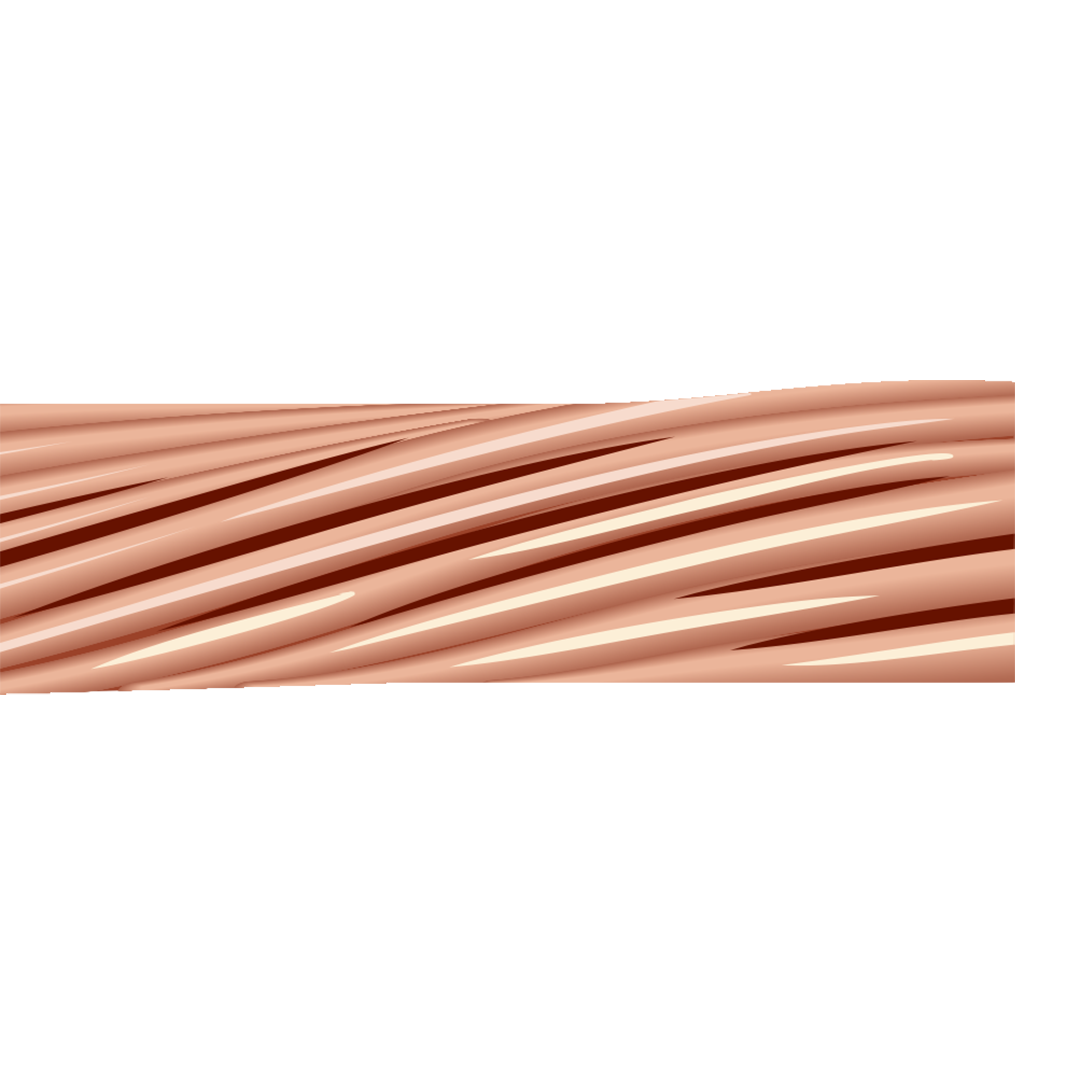

#3 Bare Copper, Stranded, 1/0 AWG, Copper, Soft Drawn

Domain Est. 1996

Website: stateelectric.com

Key Highlights: In stock $12 deliveryWire & Wire Management · Wire, Cord … Bare Copper, Stranded, 1/0 AWG, Copper, Soft Drawn. SKU: WCUBASTR19SD1/0. Manufacturer Part Number: BASTR19SD1/0….

#4 Electrical Wire & Cable Distributors

Domain Est. 1997 | Founded: 1975

Website: houwire.com

Key Highlights: Founded in 1975, Houston Wire and Cable is a master distributor of industrial wire and cable, supplying electrical distributors throughout the USA….

#5

Domain Est. 1995

Website: iewc.com

Key Highlights: IEWC is an entrusted partner to those who build the essential products and infrastructure of our connected world, providing high-quality wire, cable, and fiber ……

#6 Copper Wire Supplier

Domain Est. 1996

Website: cerrowire.com

Key Highlights: Cerrowire is a leading copper wire supplier offering MC cables, aluminum wire, and building cables for reliable electrical solutions….

#7

Domain Est. 1997 | Founded: 1958

Website: kalaswire.com

Key Highlights: Kalas is the leader in manufacturing quality copper wire & cable since 1958. Choose Kalas for bulk wire & cable, welding cable, & terminated battery cables….

#8 Heavy

Domain Est. 2012

#9 0 Gauge (1/0 Size) Copper Battery Cable Flexible Rubber with ends

Domain Est. 2014

Website: batterycablesusa.com

Key Highlights: In stock Rating 5.0 (7) This battery cable is rated from -50C to +105C and can handle up to 600 Volts so it will deliver the power you need….

Expert Sourcing Insights for 0 Awg Wire

H2: Projected Market Trends for 0 AWG Wire in 2026

The global market for 0 AWG (American Wire Gauge) wire is poised for notable shifts in 2026, driven by evolving industrial demands, technological advancements, and regulatory changes. As a heavy-gauge conductor widely used in high-current applications such as automotive systems, renewable energy installations, industrial machinery, and data centers, the trajectory of 0 AWG wire reflects broader macroeconomic and sector-specific trends.

-

Growth in Renewable Energy and EV Infrastructure

One of the primary drivers of 0 AWG wire demand in 2026 is the continued expansion of renewable energy systems, particularly solar photovoltaic (PV) arrays and battery storage solutions. These systems require high-capacity wiring to manage large DC currents between solar panels, inverters, and battery banks—all areas where 0 AWG wire is commonly specified. Similarly, the electric vehicle (EV) charging infrastructure boom is fueling demand for robust cabling. Level 2 and DC fast-charging stations often utilize 0 AWG wire to handle high amperage safely, especially in commercial and public charging networks expected to grow significantly by 2026. -

Automotive and Transportation Sector Expansion

The automotive industry, particularly in electric and hybrid vehicles, continues to be a major consumer of 0 AWG wire. As automakers increase production of EVs with larger battery capacities and higher performance, the need for high-current transmission within the vehicle architecture rises. This includes connections between battery packs, inverters, and motors—all applications suitable for 0 AWG conductors. Additionally, specialty and performance automotive markets (e.g., off-road, marine, and racing) are adopting heavier gauge wiring for reliability, contributing to sustained demand. -

Industrial Automation and Data Center Growth

Industrial automation and smart manufacturing systems require reliable power distribution, especially in high-power machinery and robotics. 0 AWG wire is often used in motor control centers and power distribution units within these environments. Concurrently, the ongoing build-out of data centers—particularly those supporting AI and cloud computing—requires robust power delivery systems. With increasing power densities in server racks and backup power systems (UPS), 0 AWG wire is increasingly specified for intra-facility power runs and generator interconnects. -

Material and Supply Chain Considerations

A key trend in 2026 will be the volatility and strategic sourcing of copper, the primary material in 0 AWG wire. Geopolitical factors, mining output constraints, and environmental regulations may affect copper supply, potentially influencing wire pricing and availability. As a result, some manufacturers are exploring alternatives such as aluminum conductors or hybrid materials, though these face limitations in conductivity and space efficiency. Recycling initiatives and circular economy practices may also gain traction, influencing sustainable sourcing and production methods. -

Regulatory and Safety Standards

Regulatory bodies such as the National Electrical Code (NEC) in the U.S. and international IEC standards continue to shape wire selection and installation practices. By 2026, updated codes may emphasize fire safety, energy efficiency, and resilience in electrical systems—factors that support the use of properly sized conductors like 0 AWG to reduce resistive losses and overheating risks. Compliance with UL, CSA, and RoHS standards will remain critical for manufacturers and installers. -

Regional Market Variations

Demand for 0 AWG wire in 2026 will vary regionally. North America and Europe are expected to lead in adoption due to aggressive decarbonization policies and infrastructure investments. Meanwhile, Asia-Pacific, particularly China and India, will see rising demand driven by urbanization, industrial expansion, and smart grid development. Emerging markets in Latin America and Africa may experience growth in off-grid solar applications, where 0 AWG wire is essential for reliable power transmission.

Conclusion

By 2026, the market for 0 AWG wire is expected to grow steadily, underpinned by the global transition toward electrification, renewable energy, and digital infrastructure. While material costs and supply chain dynamics present challenges, technological integration and regulatory support will reinforce the importance of high-capacity wiring solutions. Stakeholders across manufacturing, distribution, and installation sectors should anticipate increased demand and prepare for evolving technical requirements in this critical segment of the electrical supply chain.

Common Pitfalls When Sourcing 0 AWG Wire (Quality and IP)

Sourcing 0 AWG wire, often used in high-current applications such as automotive, solar, and electrical installations, requires careful attention to avoid quality and intellectual property (IP) issues. Below are key pitfalls to watch for:

Poor Copper Quality and Conductivity

One of the most frequent issues is receiving wire with substandard copper. Some suppliers use copper-clad aluminum (CCA) or oxygen-free copper (OFC) that doesn’t meet ASTM B3 or B8 standards, falsely labeled as pure copper. This reduces conductivity, increases resistance, and poses safety risks due to overheating.

Inadequate Insulation and Jacketing

Low-quality insulation—such as thin, non-uniform, or non-compliant PVC—can lead to premature degradation, especially in extreme temperatures or UV-exposed environments. Always verify that the insulation meets UL 1063, UL 62, or other relevant standards and is appropriate for the intended application (e.g., automotive vs. marine).

Misrepresentation of Gauge and Tolerance

Some suppliers may provide wire that is undersized (i.e., actual diameter smaller than true 0 AWG). This affects ampacity and can violate electrical codes. Always request certification or independently verify dimensions using a micrometer or caliper to ensure compliance with the American Wire Gauge (AWG) standard.

Lack of Certifications and Traceability

Reputable wire should come with certifications such as UL, CSA, RoHS, or ISO. Sourcing from suppliers without proper documentation increases the risk of counterfeit or non-compliant products. Ensure traceability through lot numbers and mill test reports to verify authenticity and material origin.

Intellectual Property (IP) Infringement

Be cautious when sourcing from manufacturers that replicate branded wire designs (e.g., mimicking color codes, labeling, or packaging of well-known brands like Welding Cable or XLP brands). Using or distributing counterfeit or IP-infringing products can lead to legal liability, recalls, or reputational damage.

Inconsistent Stranding and Flexibility

0 AWG wire should have finely stranded conductors for flexibility, especially in dynamic applications. Poor stranding (too few or uneven strands) reduces flexibility and fatigue resistance. Verify strand count and arrangement conform to applicable standards like ASTM B8.

Counterfeit or Gray Market Products

Purchasing from unauthorized distributors or unclear supply chains increases exposure to counterfeit goods. These may lack proper testing, use recycled materials, or omit critical safety features. Always source from authorized or vetted suppliers with transparent supply chains.

Inadequate Environmental and Safety Compliance

Ensure the wire meets environmental regulations (e.g., RoHS, REACH) and fire safety ratings (e.g., flame retardant, low smoke zero halogen—LSZH) if required. Non-compliant wire can fail inspections or create hazards in enclosed spaces.

By carefully vetting suppliers, requesting documentation, and independently verifying product specifications, you can avoid these common quality and IP-related pitfalls when sourcing 0 AWG wire.

Logistics & Compliance Guide for 0 AWG Wire

Overview of 0 AWG Wire

0 AWG (also known as 1/0 AWG) wire is a thick-gauge electrical conductor commonly used in high-current applications such as automotive power systems, solar installations, industrial machinery, and residential service entrances. Proper logistics handling and compliance with regulatory standards are essential to ensure safety, performance, and legal adherence throughout the supply chain.

Regulatory Standards and Compliance

0 AWG wire must comply with national and international electrical and safety standards. Key regulations include:

– National Electrical Code (NEC) – NFPA 70 (U.S.): Specifies installation requirements, ampacity ratings, and insulation types for 0 AWG conductors.

– UL Standards (Underwriters Laboratories): Requires certification marks such as UL 44 (Thermoset-Insulated Wires) or UL 83 (Thermoplastic-Insulated Wires).

– CSA C22.2 (Canada): Ensures compliance for use in Canadian electrical systems.

– RoHS and REACH (EU): Restricts hazardous substances in electrical components; applicable for imported wire.

– ASTM B3 and B8: Governs the standards for concentric-lay stranded copper and aluminum conductors.

Ensure all wire shipments include appropriate certification documentation and labeling to meet destination country requirements.

Packaging and Handling Requirements

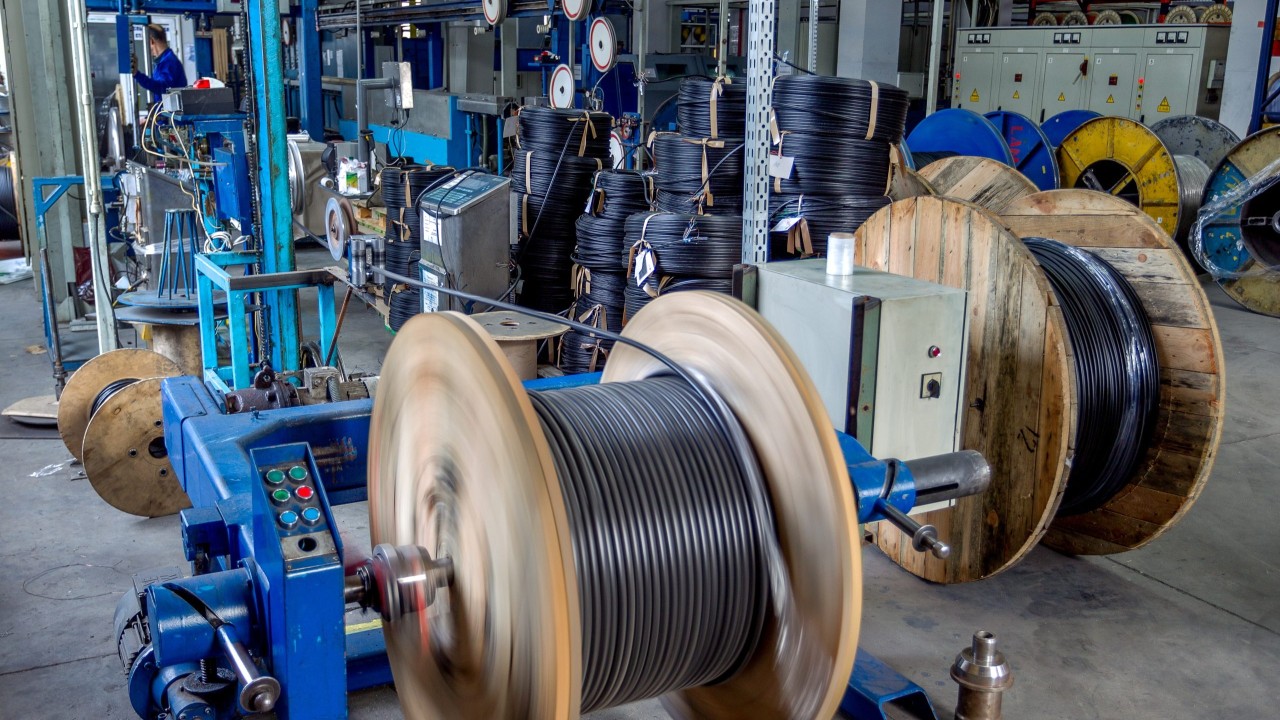

Due to its weight and rigidity, 0 AWG wire requires specialized packaging:

– Supplied on reels or spools (typically 100 ft, 250 ft, or 500 ft lengths) made of durable plastic or wood.

– Reels must be secured to prevent unwinding during transit.

– Protective caps or covers should shield the ends of the wire to prevent damage and oxidation.

– Label each package with gauge (0 AWG), conductor material (copper/aluminum), insulation type (e.g., THHN, XHHW), voltage rating, and compliance markings.

– Store reels vertically to prevent deformation and avoid stacking.

Transportation and Shipping Considerations

- Weight Management: 0 AWG copper wire weighs approximately 50–60 lbs per 100 ft; plan for proper lifting equipment (e.g., forklifts).

- Mode of Transport: Suitable for truck, rail, and sea freight. Air freight is possible but cost-prohibitive for large volumes.

- Hazard Classification: Non-hazardous under DOT and IATA regulations, unless bundled with flammable insulation materials (verify MSDS).

- International Shipments: Include commercial invoice, bill of lading, and certificates of compliance. Declare accurate HS Code (e.g., 8544.49 for insulated copper wire).

- Climate Control: Avoid prolonged exposure to moisture and extreme temperatures to prevent insulation degradation.

Storage Guidelines

- Store in a dry, climate-controlled indoor environment to prevent corrosion and insulation damage.

- Keep away from direct sunlight, chemicals, and sources of heat.

- Elevate reels off the floor using pallets to prevent moisture absorption.

- Rotate stock using FIFO (First In, First Out) to minimize aging of insulation materials.

Import/Export Documentation

For cross-border logistics, prepare:

– Certificate of Conformity (CoC)

– Test reports (e.g., dielectric strength, conductivity)

– Material Safety Data Sheet (MSDS/SDS)

– Proof of origin (e.g., for NAFTA/USMCA or EU preferential treatment)

– Customs declaration with accurate product description and HTS code

Verify import regulations in the destination country—some require third-party testing or local certification (e.g., INMETRO in Brazil, CCC in China).

Quality Assurance and Inspection

Conduct pre-shipment inspections to verify:

– Correct wire gauge (diameter ~0.3648 inches / 9.266 mm)

– Conductor material purity (e.g., 99.9% copper)

– Insulation thickness and integrity per ASTM or UL standards

– Legible and permanent printing on insulation (manufacturer, gauge, ratings)

– Reel condition and secure packaging

Maintain traceability through batch/lot numbers for compliance audits.

Disposal and Recycling Compliance

- Copper 0 AWG wire is highly recyclable; follow EPA and local regulations for scrap metal disposal.

- Insulated wire may require separation of metal and plastic components.

- Do not incinerate halogenated insulation (e.g., PVC) due to toxic emissions.

- Use certified e-waste or metal recycling facilities compliant with environmental standards.

Adhering to this logistics and compliance guide ensures safe, efficient handling of 0 AWG wire while meeting legal and quality requirements across the supply chain.

Conclusion for Sourcing 0 AWG Wire:

After evaluating various suppliers, material specifications, and application requirements, sourcing 0 AWG (American Wire Gauge) wire requires careful consideration of several key factors: conductor material (typically copper or aluminum), insulation type (such as THHN, XHHW, or USE), voltage rating, temperature tolerance, and compliance with local electrical codes (e.g., NEC in the U.S.).

0 AWG wire is commonly used in high-current applications such as main power feeds, battery banks, solar installations, automotive systems, and large-scale electrical distribution. Therefore, it is critical to source from reputable suppliers offering UL-listed or equivalent certified products to ensure safety, durability, and regulatory compliance.

Cost-effectiveness should not compromise quality—prioritizing certified, low-resistance conductors with proper stranding (stranded vs. solid) enhances performance and ease of installation. Additionally, evaluating lead times, bulk pricing, and logistical requirements will optimize procurement efforts.

In conclusion, successful sourcing of 0 AWG wire hinges on balancing technical specifications, quality assurance, and reliable supply chain partners to meet the demands of high-amperage electrical systems safely and efficiently.